A kind of black phosphorus modified polyimide composite material and its preparation method and application

A technology of polyimide and composite materials, applied in chemical instruments and methods, and other chemical processes, can solve the problems of easy aggregation of nanoparticles, degradation of composite material performance, and low surface activity of carbon fibers, so as to increase wear resistance , Improve wear resistance, reduce shear and compression stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

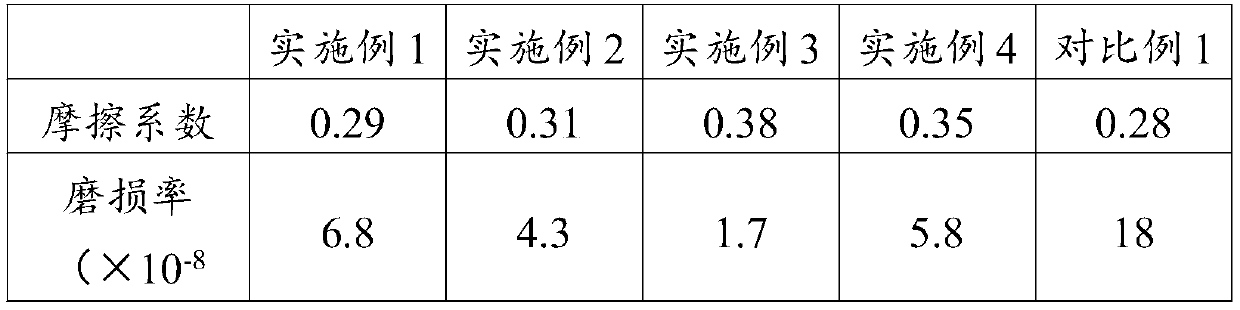

Examples

preparation example Construction

[0041] The present invention also provides the preparation method of the polyimide composite material modified by black phosphorus, comprising the following steps:

[0042] (a) mixing polyimide, polytetrafluoroethylene, carbon fiber, graphite, polyphenylester and black phosphorus in absolute ethanol to obtain a compound;

[0043] (b) removing the absolute ethanol in the resulting mixture to obtain a dry mixture;

[0044] (c) Pressurizing and sintering the obtained dry mixture to obtain a black phosphorus-modified polyimide composite material.

[0045] The invention mixes polyimide, polytetrafluoroethylene, carbon fiber, graphite, polyphenylester and black phosphorus in absolute ethanol to obtain a mixture. The invention mixes polyimide, polytetrafluoroethylene, carbon fiber, graphite, polyphenylester and black phosphorus in absolute ethanol, and can mix the materials of each object very uniformly. In a specific embodiment of the present invention, the ratio of the mass of ca...

Embodiment 1

[0051] Seal 10g of red phosphorus, 2g of tin, and 1g of tin iodide in a quartz ampoule, vacuum (10 -1 Pa) in a tube furnace at 1°C·min -1 Heating to 700°C and keeping the temperature constant for 6h, then at 0.2°C·min -1 Lower the temperature to 450°C, keep it warm for 1 hour and then lower it to room temperature within 3 hours, and separate the target product from the residual mineralizer by refluxing toluene to obtain crude black phosphorus. Using 300mL of absolute ethanol as the liquid-phase stripping medium, liquid-phase stripped the crude black phosphorus, ultrasonic power 500W, time 30min, after centrifugation, take the supernatant, centrifuge, and dry to obtain black phosphorus.

[0052] Weigh 74.5g of polyimide, 5g of polytetrafluoroethylene, 5g of carbon fiber, 5g of flake graphite, 10g of polyphenylene, and 0.5g of nano-black phosphorus, mix them evenly in 300mL of absolute ethanol, and dry the mixed powder Put it into the mold, gradually raise the temperature from...

Embodiment 2

[0055] Seal 40g red phosphorus, 4g tin, and 1g tin iodide in a quartz ampoule, vacuum (10 -1 Pa) in a tube furnace at 2°C·min -1 Heating to 600°C and keeping the temperature constant for 7h, then at 0.5°C·min -1 Lower the temperature to 500°C, keep it warm for 2 hours and then lower it to room temperature within 5 hours, and separate the target product from the residual mineralizer by refluxing toluene to obtain crude black phosphorus. Using 400mL of absolute ethanol as the liquid-phase stripping medium, liquid-phase stripping the crude black phosphorus, ultrasonic power 600W, time 50min, after centrifugation, take the supernatant, centrifuge, and dry to obtain black phosphorus.

[0056] Weigh 64g of polyimide, 10g of polytetrafluoroethylene, 5g of carbon fiber, 10g of flake graphite, 10g of polyphenylene, and 1g of nano black phosphorus, mix them evenly in 400mL of absolute ethanol, and put the mixed powder into The mold was gradually heated from room temperature to 375°C u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com