Soft-touch antibacterial wood-plastic composite material and preparation method thereof

A composite material and antibacterial wood technology, which is applied in the field of soft-touch antibacterial wood-plastic composite materials and its preparation, can solve the problems of hidden dangers to the health of residents and children, affecting the appearance of materials, and mildew on the surface, so as to reduce the number of bacteria, improve the appearance, and prevent mildew Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

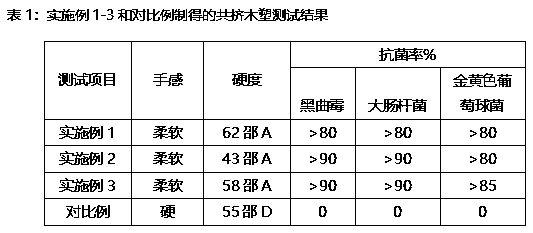

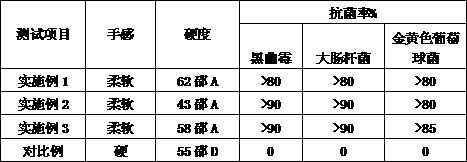

Examples

Embodiment 1

[0042] S1, the core layer material according to the following mass parts: 25 parts of HDPE resin, 50 parts of poplar wood powder, 20 parts of calcium carbonate, 3 parts of silane coupling agent, 2 parts of PE wax, 0.2 parts of 1076 and 168 are put into the high-speed mixer Stir for 5 minutes;

[0043]S2. Put the mixed material in step S1 into the twin-screw extruder through the main feeding hopper, melt, extrude, and granulate; wherein, the barrel temperature of the twin-screw extruder is 150°C, and the degree of vacuum is -0.06 to -0.08MPa;

[0044] S3, the surface layer material according to the following mass parts: 70 parts of EVA, 20 parts of sarin resin, 3 parts of zinc borate, 1 part of nano-zinc oxide, 1 part of nano-silver oxide, 5 parts of maleic anhydride grafted polyethylene, azo 1 part of dimethylamide, 0.2 parts of 1076 and 168 in total, 0.4 parts of light stabilizer 944 were put into a high-speed mixer and stirred for 3 minutes;

[0045] S4. Put the blended pe...

Embodiment 2

[0047] S1, the core layer material according to the following mass parts: 45 parts of PP resin, 40 parts of rice husk powder, 10 parts of talcum powder, 4 parts of maleic anhydride grafted polypropylene, 1 part of lubricant calcium stearate, and 1010 parts of antioxidant and 0.4 parts of 168 were put into a high-speed mixer and stirred for 3 minutes;

[0048] S2. Put the mixed material in step S1 into the twin-screw extruder through the main feeding hopper, melt, extrude, and granulate; wherein, the barrel temperature of the twin-screw extruder is 210°C, and the degree of vacuum is -0.06 to -0.08MPa;

[0049] S3, the surface layer material according to the following mass parts: 75 parts of EVA, 10 parts of sarin resin, 4 parts of zinc borate, 2 parts of nano-zinc oxide, 2 parts of nano-silver oxide, 2 parts of maleic anhydride grafted polypropylene, azo 3 parts of diisopropyl diformate, 1 part of antioxidant 1010 and 168, and 1 part of light stabilizer 770 were put into a hig...

Embodiment 3

[0052] S1, the core layer material according to the following mass parts: 30 parts of HDPE resin, 45 parts of straw powder, 15 parts of short glass fiber, 5 parts of titanate coupling agent, 3 parts of lubricant glyceryl monostearate, antioxidant A total of 0.3 parts of 1076 and DSTP were put into a high-speed mixer and stirred for 4 minutes;

[0053] S2. Put the mixed material in step S1 into the twin-screw extruder through the main feeding hopper, melt, extrude, and granulate; wherein, the barrel temperature of the twin-screw extruder is 180°C, and the degree of vacuum is -0.06 to -0.08MPa;

[0054] S3, the surface layer material according to the following mass parts: 65 parts of EVA, 12 parts of sarin resin, 5 parts of zinc borate, 3 parts of nano-zinc oxide, 3 parts of nano-silver oxide, 8 parts of maleic anhydride grafted polyethylene, bicarbonate Put 2 parts of sodium, 0.6 parts of antioxidant 1076 and DSTP in total, and 2 parts of light stabilizer 622 into a high-speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com