Rubber plug for stabilizing well wall of limestone deep well and preparation method thereof

A well wall stability and rubber plug technology, which is applied to chemical instruments and methods, adhesives, epoxy resin glue, etc., can solve the problems of short gelation time of liquid rubber plugs, early gelation and curing, unfavorable deep well operations, etc., to achieve solidification Controllable time, good toughness, and long effective period of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

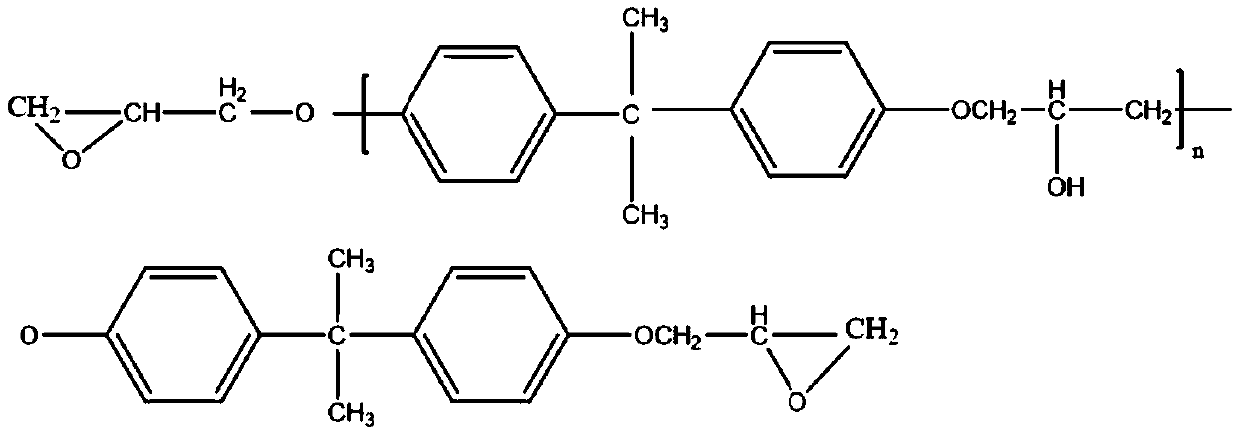

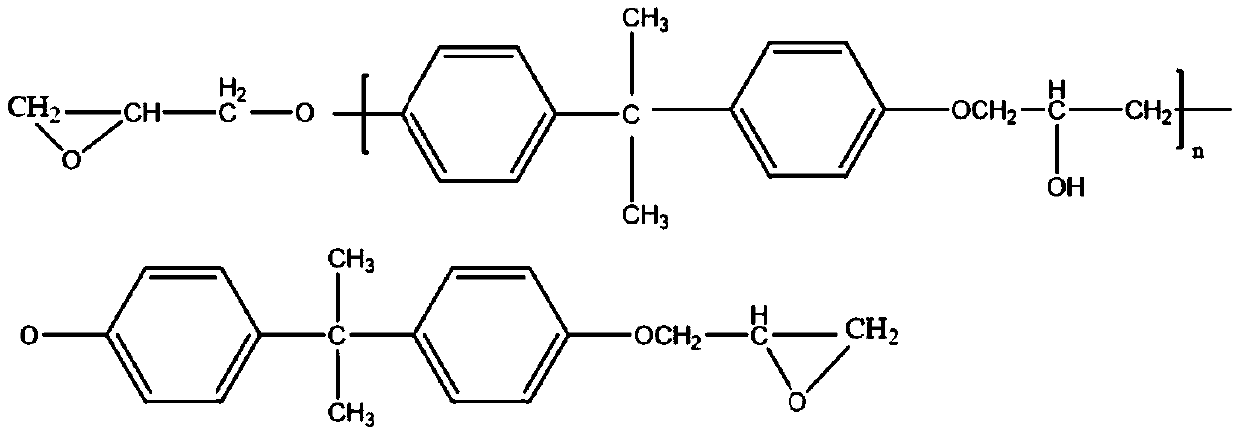

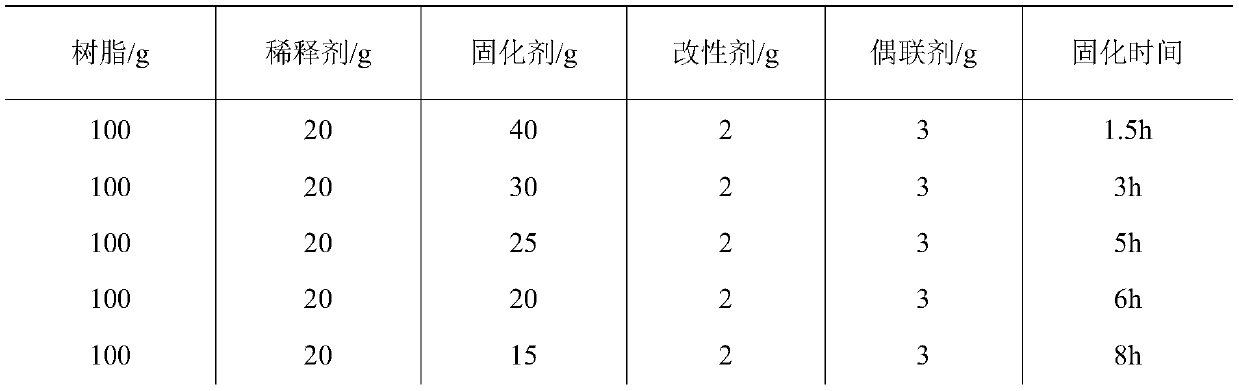

Method used

Image

Examples

Embodiment 1

[0059] 20g of butyl glycidyl ether was added to 100g of epoxy resin, and after stirring uniformly, 25g of diaminodiphenyl sulfone and 3g of titanate coupling agent were added to the above system and stirred at 70°C for 0.5h after stirring uniformly. The prepared liquid was placed under a high-speed mixer with a stirring speed of 200 r / min, and 2 g of modifier microsilica powder was weighed and slowly added to the prepared liquid and stirred for 20 min. That is, the high-strength well-wall-stabilizing rubber plug of the present invention is obtained. It was placed in a sample bottle and sealed, placed in a constant temperature oil bath at 100°C, aged for 30h, the volume shrinkage was less than 1%, and the formed cured product had high strength and good adhesion.

[0060] Wellbore Stability Simulation Test:

[0061] The cementing ability of the high-strength resin rubber plug provided in this example to rock debris was investigated. The specific implementation process is as fo...

Embodiment 2

[0063] First add 20g of butyl glycidyl ether to 100g of epoxy resin, stir evenly, add 25g of diaminodiphenyl sulfone and 3g of titanate coupling agent to the above system, stir at 70°C for 0.5h and stir evenly . The prepared liquid was placed under a high-speed mixer with a stirring speed of 200 r / min, and 2 g of nano-calcium carbonate particles were weighed and slowly added to the prepared liquid and stirred for 20 min. That is, the high-strength well-wall-stabilizing rubber plug of the present invention is obtained. It was placed in a sample bottle and sealed, placed in a constant temperature oil bath at 130°C, aged for 30h, the volume shrinkage was less than 1%, and the formed cured product had high strength and good adhesion.

[0064] Wellbore Stability Simulation Test:

[0065] The cementing ability of the high-strength resin rubber plug provided in this example to rock debris was investigated. The specific implementation process is as follows: put an appropriate amoun...

Embodiment 3

[0067] First add 20g of butyl glycidyl ether to 100g of epoxy resin, stir evenly, add 25g of diaminodiphenyl sulfone and 3g of titanate coupling agent to the above system, stir at 70°C for 0.5h and stir evenly . The prepared liquid was placed under a high-speed mixer with a stirring speed of 200 r / min, and 2 g of fumed silica was weighed and slowly added to the prepared liquid and stirred for 20 min. That is, the high-strength well-wall-stabilizing rubber plug of the present invention is obtained. It was placed in a sample bottle and sealed, placed in a constant temperature oil bath at 150°C, aged for 30h, the volume shrinkage was less than 1%, and the formed cured product had high strength and good adhesion.

[0068] Wellbore Stability Simulation Test:

[0069] The cementing ability of the high-strength resin rubber plug provided in this example to rock debris was investigated. The specific implementation process is as follows: put an appropriate amount of limestone rock f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com