A gradient phase change heat storage body and its preparation method

A phase change heat storage and gradient technology, which is applied in heat storage equipment, lighting and heating equipment, chemical instruments and methods, etc., can solve the problem of reducing the proportion of sensible heat, and can not use the temperature difference between the inner and outer layers of the heat storage for efficient phase transformation heat, no hierarchical sequential heat exchange, etc., to achieve the effects of reducing thermal insulation cracks, efficient heat transfer and storage, and slowing down leakage or loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

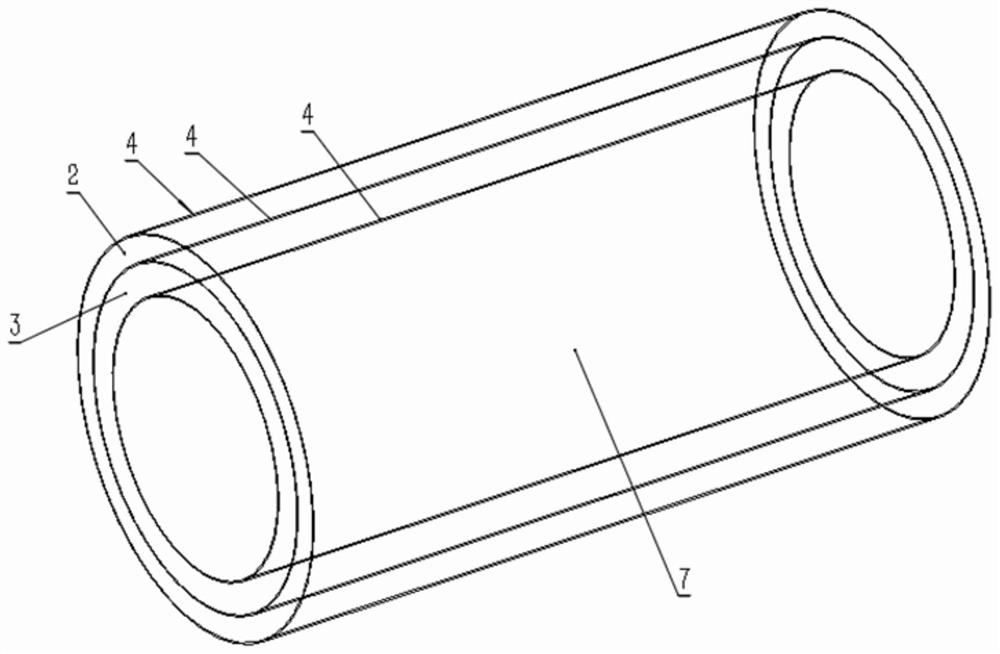

[0030] The tubular shell 1 is made of a plastic cylinder with a diameter of 200mm, a length of 300mm and a wall thickness of 2mm.

[0031] The heat-conducting separation film 4 is made of aluminum foil, and the heat releasing pipe 6.1 and the heat taking pipe 6.2 are made of copper pipe with an inner diameter of 12mm, bent into a U shape, and the length including the external section is 400mm. The formed central heat exchange assembly 6 has an outer diameter of 90 mm.

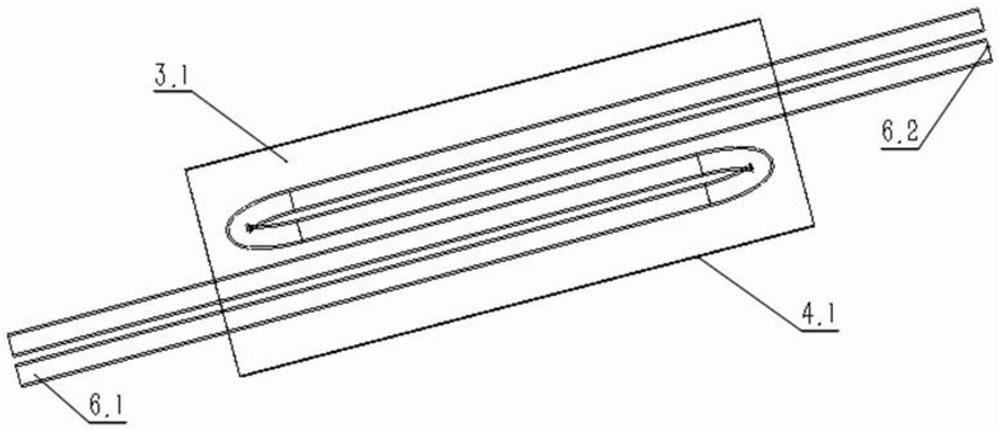

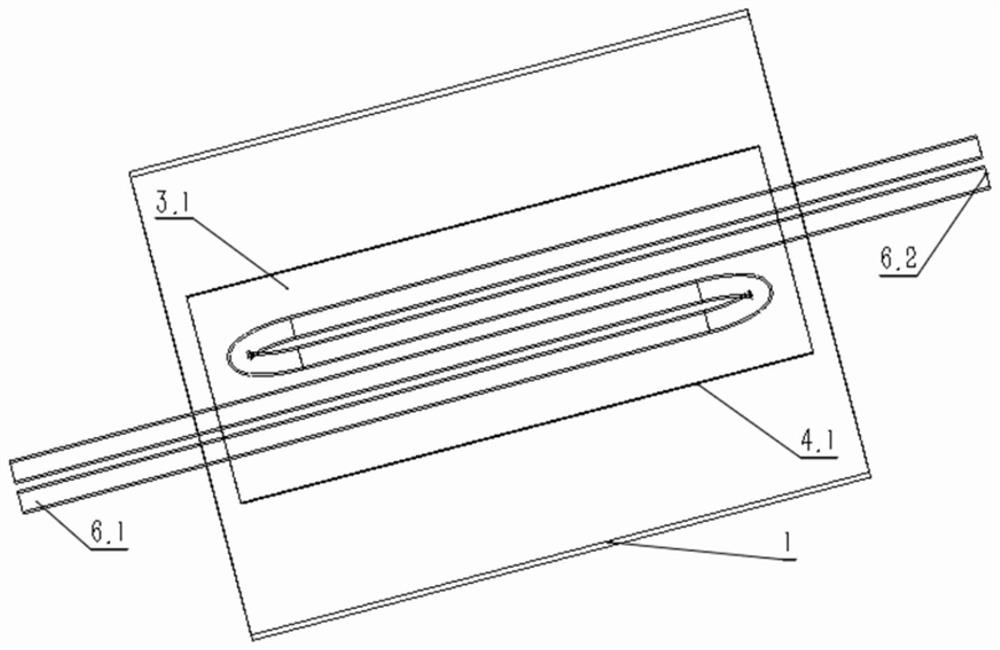

[0032] The gradient phase change unit group 7 is set to 3 groups, the single layer thickness is 7.5mm, the total layer thickness is 45mm, and the overall outer diameter is 180mm. figure 2 is a structural schematic diagram of a group of gradient phase transition unit group 7, from figure 2 It can be seen from the figure that a group of gradient phase change unit group 7 only includes one cylindrical inner phase transition layer and one outer cylindrical phase transition layer, and one cylindrical outer phase ...

Embodiment 2

[0037] The tubular shell 1 is made of a plastic cylinder with a diameter of 290mm, a length of 500mm and a wall thickness of 4mm.

[0038] The heat-conducting separation film 4 is made of copper foil, and the heat release pipe 6.1 and the heat taking pipe 6.2 are made of copper tube with an inner diameter of 12mm, which is wound into a spiral shape, and the length including the external section is 600mm. The outer diameters of the heat releasing pipe 6.1 and the heat taking pipe 6.2 are 110 mm and 80 mm respectively, and the outer diameter of the central heat exchange component 6 formed is 120 mm.

[0039] The gradient phase change unit group 7 is set to 3 groups, with a single layer thickness of 12.5 mm, a total layer thickness of 75 mm, and an overall outer diameter of 270 mm.

[0040] From the inside to the outside, the cylindrical partial inner phase change layer and the cylindrical outer partial phase change layer (3.1, 2.1, 3.2, 2.2, 3.3, 2.3) select polyethylene oxide 1...

Embodiment 3

[0044] The tubular shell 1 is made of a plastic cylinder with a diameter of 200mm, a length of 300mm and a wall thickness of 2mm.

[0045] The heat-conducting separation film 4 is made of graphite paper, the heat release pipe 6.1 and the heat taking pipe 6.2 are made of copper tube with an inner diameter of 12mm, bent into multiple U shapes, and the length including the external section is 400mm. The formed central heat exchange assembly 6 has an outer diameter of 90 mm.

[0046] The gradient phase change unit group 7 is set to 3 groups, with a single layer thickness of 7.5 mm, a total layer thickness of 45 mm, and an overall outer diameter of 180 mm.

[0047] From the inside to the outside, the cylindrical inner phase change layer and the cylindrical outer phase change layer (3.1, 2.1, 3.2, 2.2, 3.3, 2.3) are sequentially selected from polyethylene oxide 2000, polyethylene oxide 1500, polyethylene oxide 1000, polyoxyethylene Ethylene 800, polyethylene oxide 600, and polyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com