GaN-based p-GaN enhanced HEMT device and manufacturing method thereof

An enhancement-mode, p-gan technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of p-GaN difficulty, device threshold instability, low activation rate, etc., to achieve cap layer thickness and Reduced doping concentration requirements, low doping concentration and thickness requirements, and improved depletion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

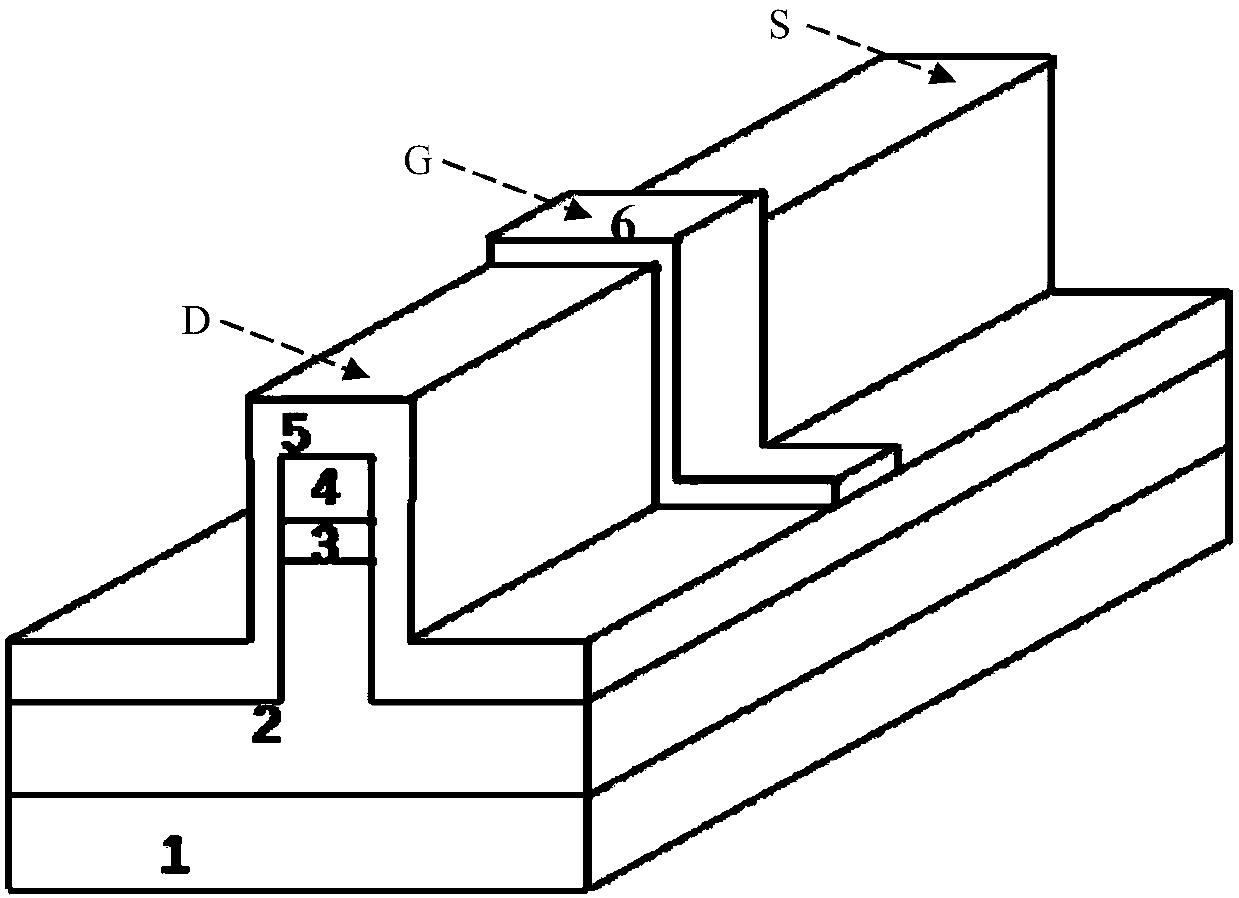

[0127] Embodiment 1: Fabricate a p-GaN / AlGaN / GaN enhanced HEMT device on a Si substrate.

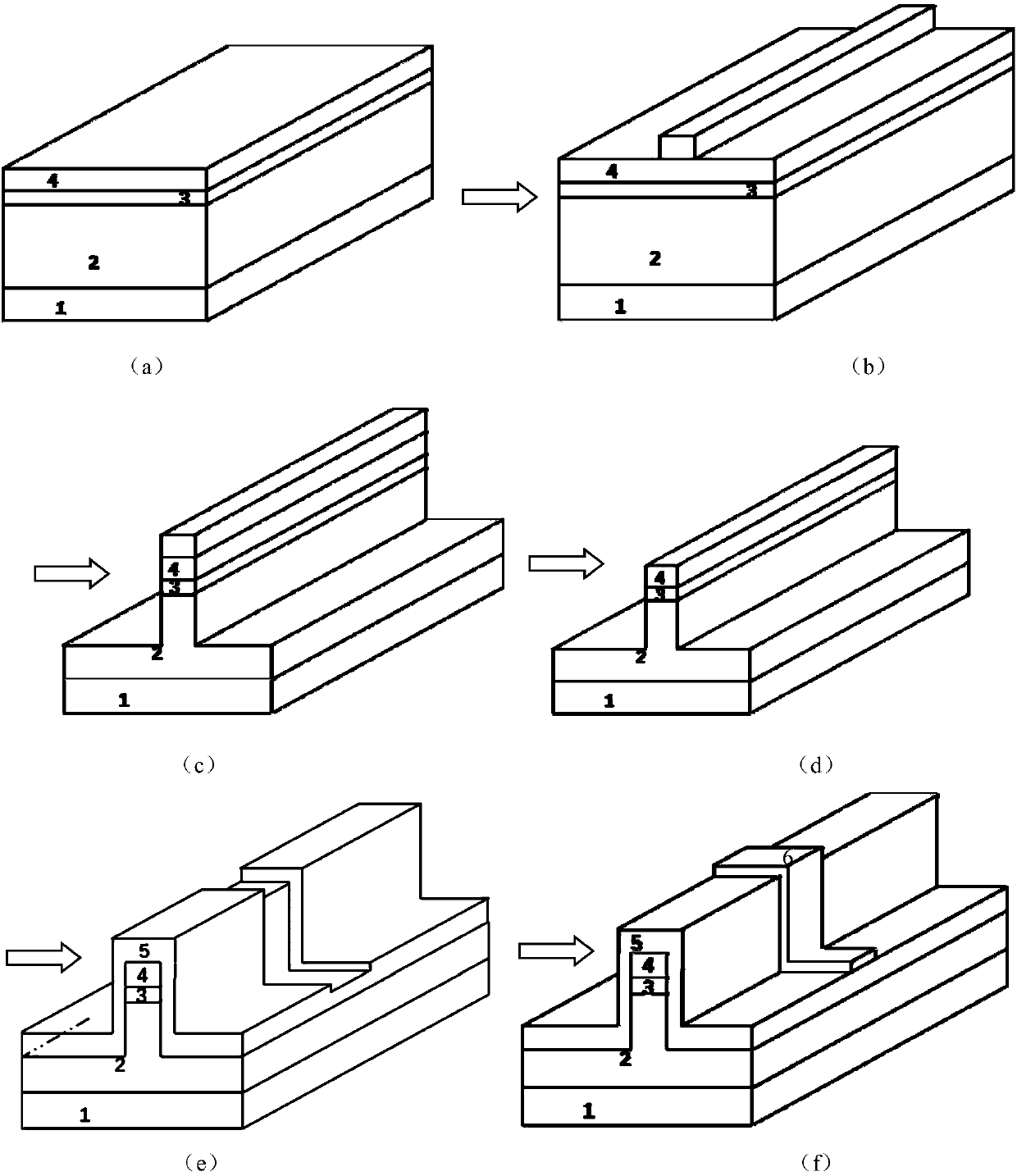

[0128] Step 1: growing a buffer layer.

[0129] A low-temperature AlN buffer layer and a GaN buffer layer were grown on a Si substrate by MOCVD, wherein the AlN low-temperature growth temperature was 700° C., the thicknesses were 20 nm, and the thickness of the GaN buffer layer was 2 μm.

[0130] Step 2: growing a GaN channel layer and a barrier layer.

[0131] GaN channel layer and AlGaN barrier layer are epitaxially grown on the buffer layer by MOCVD, the thicknesses are 5nm and 20nm respectively, forming the following figure 2 The device structure shown in (a).

[0132] Step 3: growing a mask layer resistant to Cl-based etching.

[0133] 50nm thick Si grown by LPCVD 3 N 4 , Si 3 N 4 The Cl-based etching resistance can be used as a mask layer for etching to form a tunnel structure.

[0134] Step 4: Photolithographic graphics.

[0135] Using a contact photolithography machine,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com