Anode materials for lithium ion battery and preparation methods thereof

A technology for lithium-ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of poor conductivity of lithium-ion batteries, cannot protect Si nanoparticles from powdering and falling off, and cannot ensure that the carbon shell is not broken, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

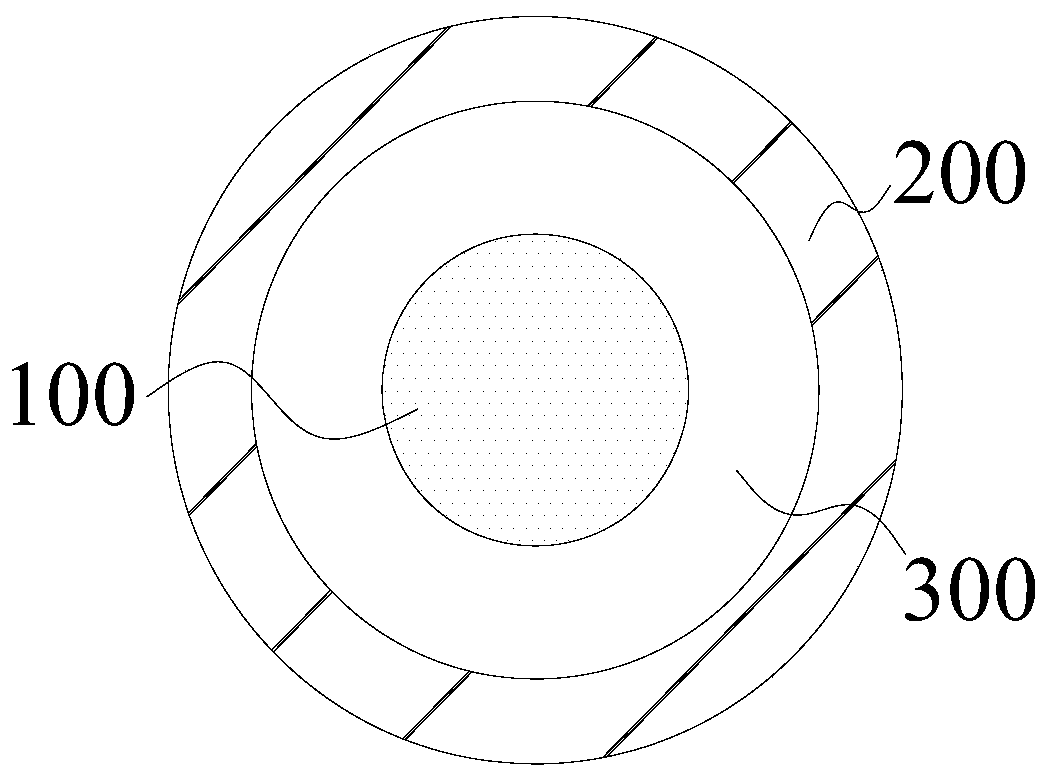

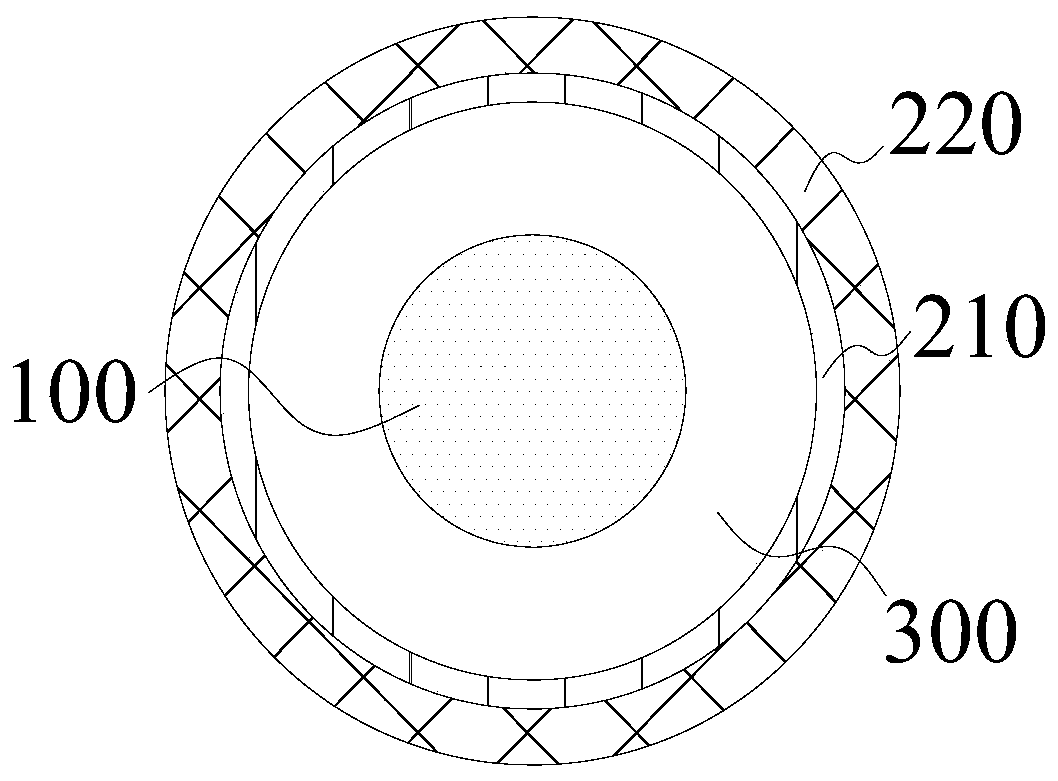

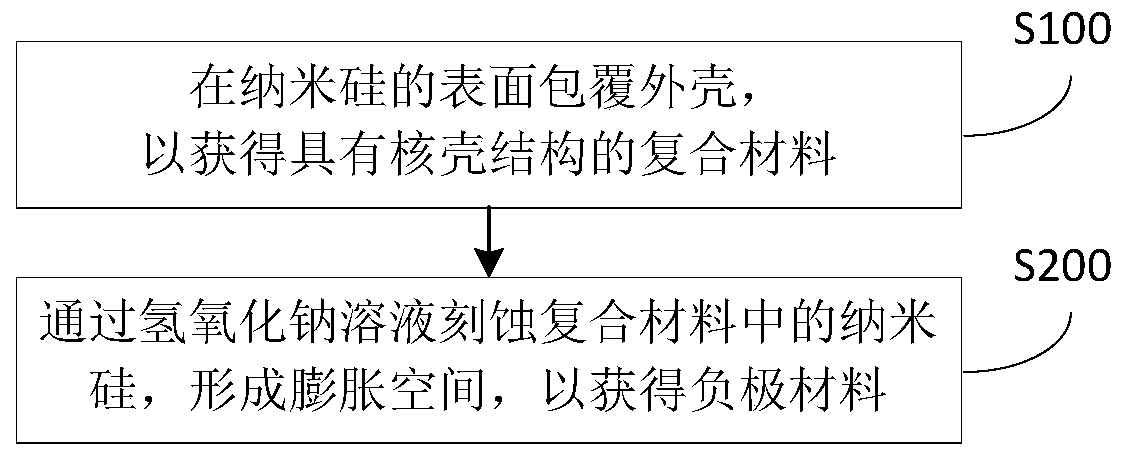

[0046] In another aspect of the present invention, the present invention proposes a method for preparing a negative electrode material for a lithium ion battery. According to an embodiment of the present invention, refer to image 3 , the preparation method comprises:

[0047]S100: Coating a shell on the surface of nano-silicon to obtain a composite material with a core-shell structure.

[0048] In this step, a shell is coated on the surface of the nano-silicon to obtain a composite material with a core-shell structure, wherein the material forming the shell includes graphene.

[0049] According to the embodiment of the present invention, those skilled in the art can design the specific steps of coating the shell on the surface of the nano-silicon to obtain the core-shell structure according to the specific material of the shell. In some embodiments of the invention, reference Figure 4 , step S100 may include:

[0050] S110: Prepare graphene oxide solution and nano-silico...

Embodiment 1

[0064] In this example, an anode material for a lithium ion battery was prepared. The specific steps are:

[0065] (1) The graphene oxide solution with a solid content of 1.34% was prepared into 1L of graphene oxide (GO) solution of 1mg / mL, and dispersed by ultrasonic stirring for 2 hours, and the stirring speed was 220rpm / min; weighed 7g of polypyrrolidone (PVP K-30) was dissolved in 500mL deionized water, then weighed 1g of Si nanoparticles (30nm particle size) and added to the PVP solution, ultrasonically stirred for 1 hour, the stirring speed was 220rpm / min, to obtain PVP dispersion dispersion of Si nanoparticles.

[0066] (2) Then the GO solution was stirred at a speed of 330rpm / min, and the Si dispersion was added dropwise to prepare a uniformly mixed GO / Si / PVP dispersion; then the GO / Si / PVP dispersion was spray-dried, wherein, The air inlet temperature of the spray drying is 199°C, the wind speed is 80%, the speed of the sampling peristaltic pump is 30%, the needle is...

Embodiment 2

[0071] In this embodiment, the cycle performance test and the rate characteristic test are performed after the negative electrode material of the embodiment 1 is made into a button battery.

[0072] The button battery of this embodiment has an initial discharge capacity of 2216mAh / g and an initial coulombic efficiency of 73.2% at a rate of 0.1C, and a discharge capacity of 1390mAh / g after 50 cycles with a capacity retention rate of 82.23%.

[0073] The button battery of this embodiment has a discharge capacity of 1601mAh / g at a rate of 0.1C, a discharge capacity of 1542mAh / g at a rate of 0.2C, a discharge capacity of 1503mAh / g at a rate of 0.5C, and a capacity of 1503mAh / g at a rate of 1C. The discharge capacity of the battery is 1470mAh / g, the discharge capacity at 2C rate is 1431mAh / g, and the discharge capacity at 3C rate is 1379. To sum up, the button battery of this embodiment has a capacity retention rate of 86.1% at different rates from 0.1C to 3C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com