Preparation method of wave-absorbing continuous SiCN ceramic fiber

A ceramic fiber and wave type technology, which is applied in the field of high-performance fiber preparation, can solve the problems of difficult introduction of electromagnetic waves, increased loss, and adverse effects on wave-absorbing performance, and achieve the effects of reduced reflection, reduced atomic ratio, and excellent wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention proposes a method for preparing a wave-absorbing continuous SiCN ceramic fiber, comprising the following steps:

[0023] S1: Place the polycarbosilane crosslinked fiber in a vacuum sintering furnace and vacuumize;

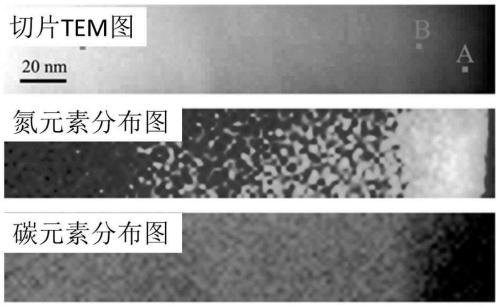

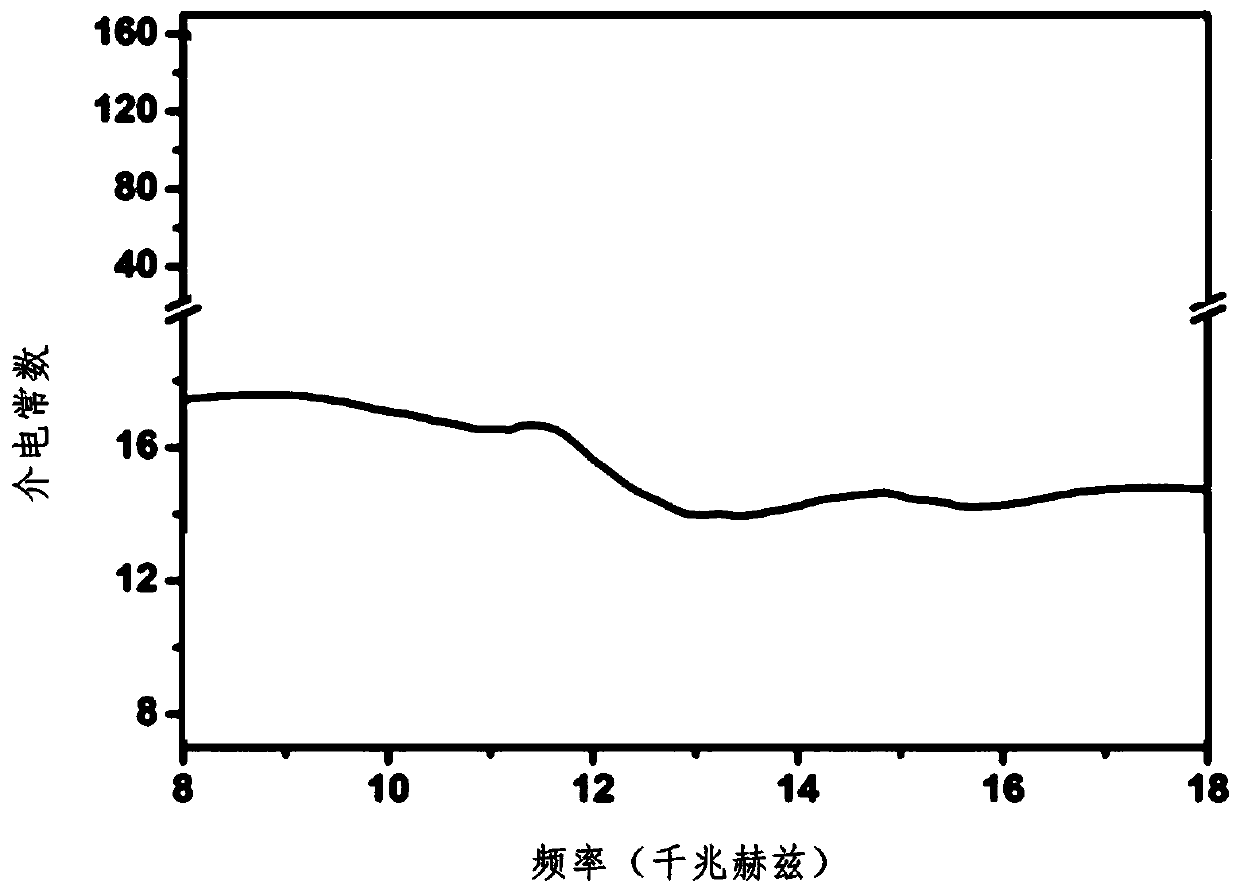

[0024] In the step S1, the C / Si atomic ratio of the polycarbosilane crosslinked fiber is 1.5-2, the weight retention rate in nitrogen at 1000°C is higher than 80%, and it will not melt and deform at 400°C; it has excellent wave-absorbing properties Ceramic fibers require a certain amount of SiC, Si 3 N 4 Different from C, etc., the selected polycarbosilane cross-linked fiber raw material can provide Si and C, polycarbosilane cross-linked fiber raw material can form SiC at high temperature, and then part of SiC becomes Si through atmosphere reaction 3 N 4 , the raw materials can meet the needs of use and are rich in sources and cheap in price.

[0025] The vacuuming is until the pressure in the vacuum sintering furnace is lower than ...

Embodiment 1

[0044] This embodiment provides a method for preparing a wave-absorbing continuous SiCN ceramic fiber, comprising the following steps:

[0045] S1: Put the polycarbosilane cross-linked fiber in a vacuum sintering furnace and evacuate to make the pressure in the furnace lower than 1Pa;

[0046] S2: Raise the temperature of the vacuum sintering furnace to 400°C, and then feed a mixture of ammonia and helium with a volume ratio of 1:1 at a flow rate of 1.5L / min until the pressure in the vacuum sintering furnace is 85kPa;

[0047] S3: Continue to feed the mixed gas of ammonia and helium at a flow rate of 1.5L / min, and at the same time raise the temperature in the vacuum sintering furnace from 400°C to 900°C at a heating rate of 1°C / min, and keep it in the vacuum sintering furnace The pressure remains unchanged at 85kPa, and stop feeding the mixed gas of ammonia and helium into the vacuum sintering furnace after the temperature reaches 900°C;

[0048] S4: Control the pressure in t...

Embodiment 2

[0057] This embodiment provides a method for preparing a wave-absorbing continuous SiCN ceramic fiber, comprising the following steps:

[0058] S1: Put the polycarbosilane cross-linked fiber in a vacuum sintering furnace and evacuate to make the pressure in the furnace lower than 1Pa;

[0059] S2: Raise the temperature of the vacuum sintering furnace to 400°C, and then feed a mixture of ammonia and helium with a volume ratio of 4:1 at a flow rate of 2.0L / min until the pressure in the vacuum sintering furnace is 95kPa;

[0060] S3: Continue to feed the mixed gas of ammonia and helium at a flow rate of 2.0L / min, and at the same time raise the temperature in the vacuum sintering furnace from 400°C to 900°C at a heating rate of 1.5°C / min, and keep the temperature in the vacuum sintering furnace The pressure remains unchanged at 95kPa, and stop feeding the mixed gas of ammonia and helium into the vacuum sintering furnace after the temperature reaches 900°C;

[0061] S4: Control th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

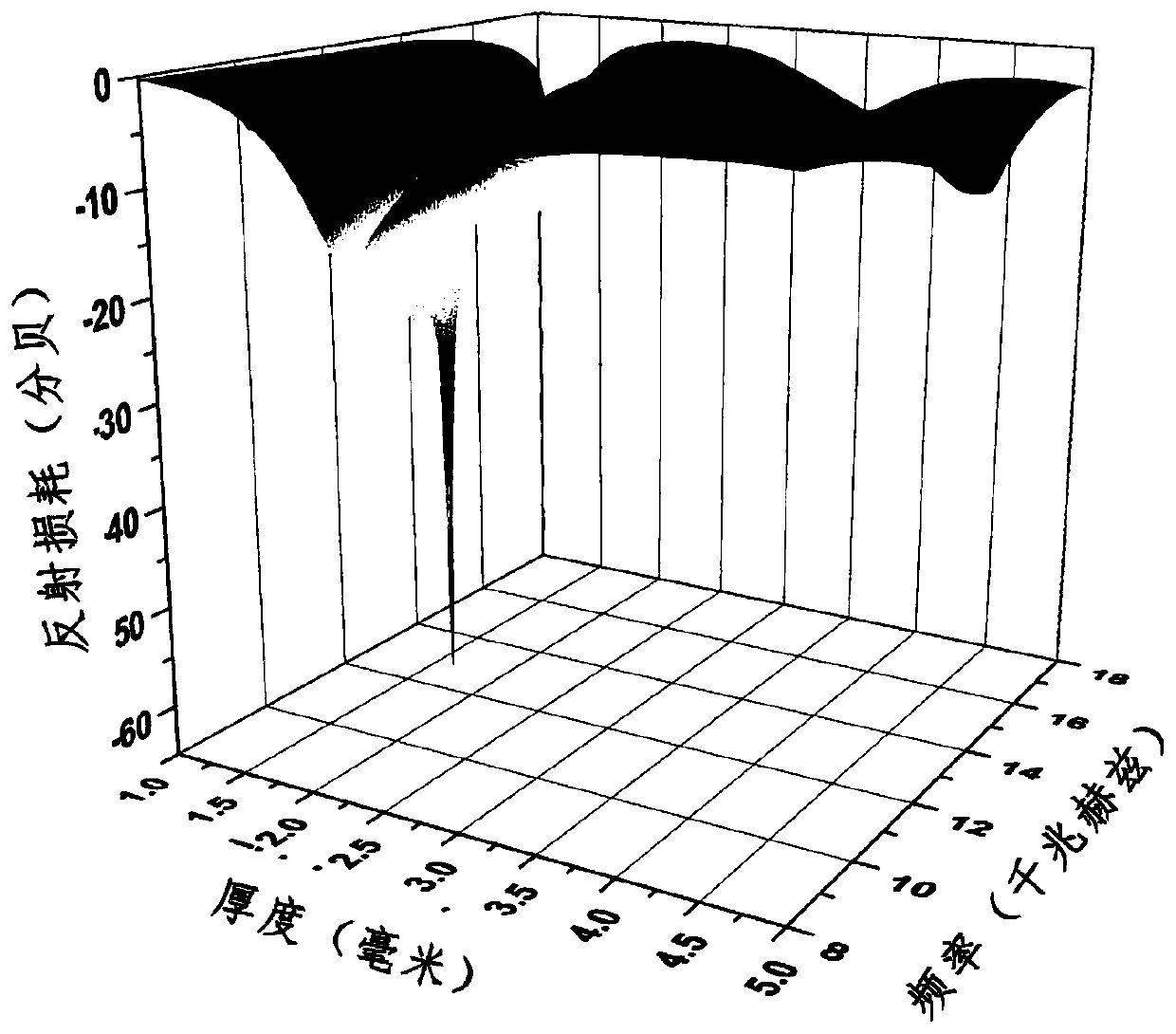

| Effective absorption bandwidth | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com