Silicone slurry residue treatment system and treatment technology thereof

A processing system and organosilicon technology, applied in the direction of organic chemistry, process efficiency improvement, inorganic chemistry, etc., can solve the problems of secondary pollution, effective resources, waste, etc., and achieve the effect of saving investment, improving utilization efficiency, and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below through specific examples. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

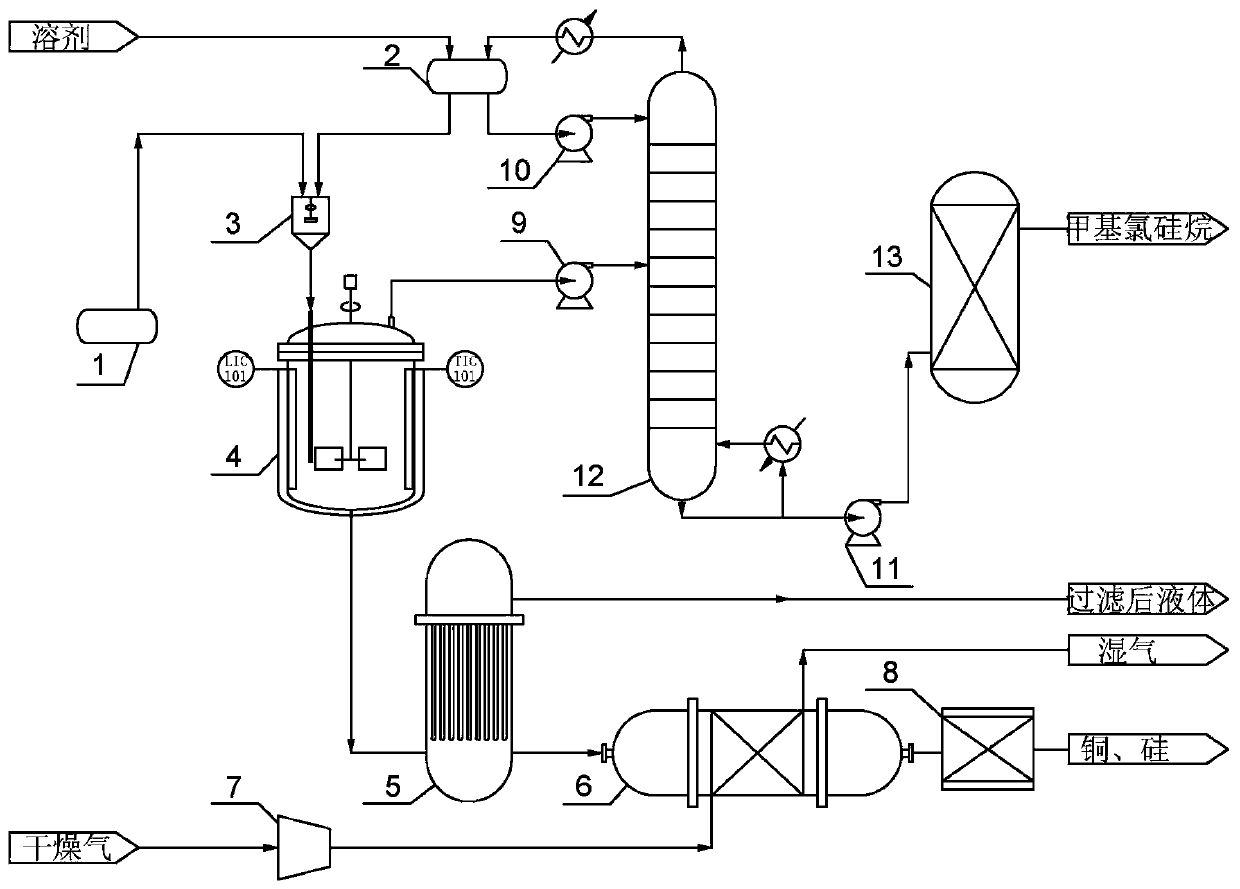

[0035] Such as figure 1 As shown, this embodiment discloses for the first time an organic silicon pulp and slag treatment system integrating evaporation, rectification, cracking and other processes, mainly including a pulp and slag tank 1, an azeotropic solvent tank 2, a mixing tank 3, and an azeotropic evaporation kettle 4. Distillation product distillation tower 12, high boiling cracking device 13, residue filter 5, solid drying tower 6, waste powder deactivation device 8.

[0036] The organic silicon slurry tank 1 and the azeotropic solvent tank 2 are respectively connected to the two inlets of the mixing tank 3, and the mixing tank 3 is used to store the organic silicon slurry raw material and the azeotropic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com