Transition metal single-atom catalyst as well as preparation method and application thereof

A transition metal and transition metal salt technology, applied in the field of micro-nano material preparation, can solve problems such as inability to improve, complex synthesis methods, intensified thermal motion, etc., and achieve the effects of reducing surface pollution, avoiding metal agglomeration, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing a nickel single-atom catalyst, comprising the steps of:

[0045] 1) Weigh 0.2mmol nickel acetate and 0.6mmol o-phenanthroline into a test tube, add 2mL ethanol, stir magnetically until completely dissolved to obtain a clear and transparent solution;

[0046] 2) After the reaction is completed, weigh 69.6mg of carbon black and add it to the above solution of Ketjenblack EC-300J type, mix evenly, heat in a water bath at 60°C for 4h, and then dry it in an oven at 80°C for 12h to obtain a crude product;

[0047] 3) The crude product obtained above was heated in an argon atmosphere at 10°C·min -1 The heating rate is raised to 580°C, and kept at this temperature for 2 hours. After the completion, the temperature is naturally lowered to room temperature, and the Ni single-atom catalyst is obtained, which is recorded as Ni-SAC. The Ni-SAC can be detected by the ICP-AES method. The supported amount of Ni atoms was 6.0 wt%.

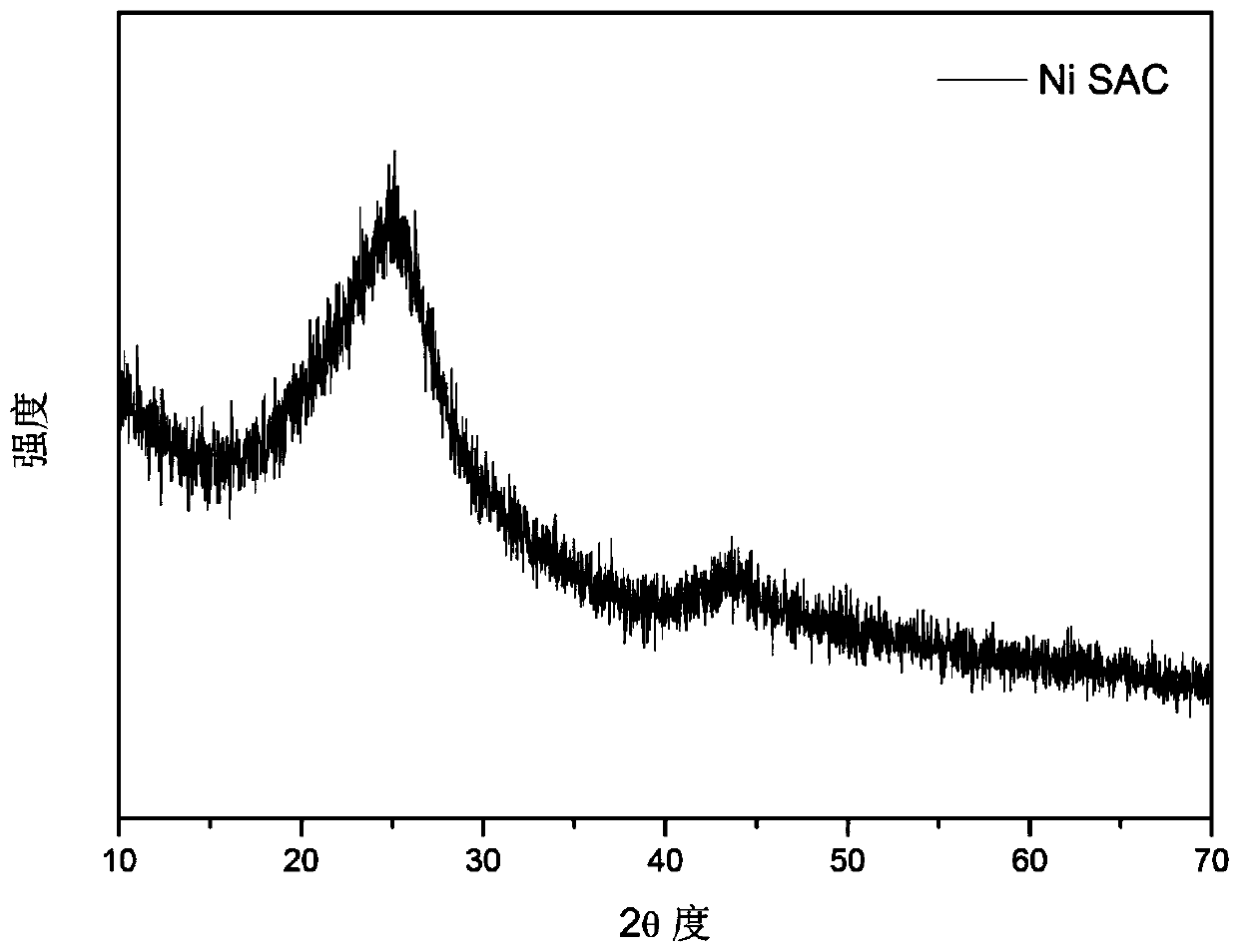

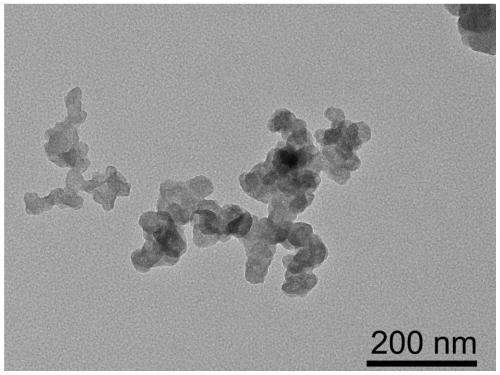

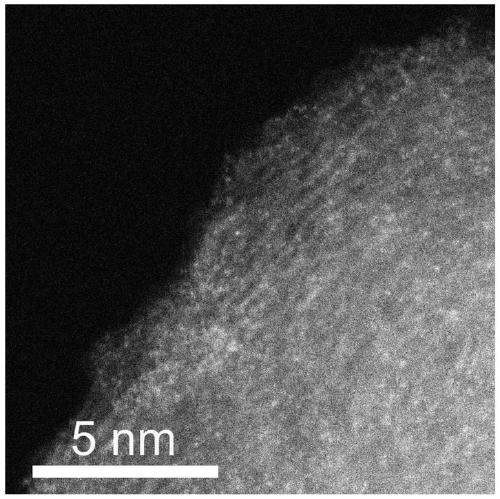

[0048] figure 1 The middle c...

Embodiment 2-4

[0054] Repeat embodiment 1, its difference is only to change nickel acetate into nickel chloride, nickel nitrate, nickel sulfate. The Ni single-atom catalyst obtained is not significantly different from the single-atom catalyst obtained in Example 1, and by ICP-AES method, it can be detected that the Ni atom loading in the Ni-SAC is 6 wt%.

[0055] Figure 5 It is the XRD pattern of the Ni single-atom catalyst synthesized by embodiment 2-4, as can be seen from the figure, the Ni single-atom catalyst that adopts nickel chloride, nickel nitrate, nickel sulfate all only appears the peak of carbon black, and The peak of Ni or its compound did not appear. This also shows that the species of anions in transition metal salts have no significant effect on the formation of single-atom catalysts.

Embodiment 5

[0057] Repeat Example 1, its difference is only to change Ketjenblack EC-300J type carbon black into Vulcan XC-72 type carbon black, the catalyzer that obtains is single-atom catalyst, and by ICP-AES method, can detect in this Ni-SAC , the loading of Ni atoms was 4.5wt%.

[0058] Figure 6 Shown are the Ni single-atom XRD patterns synthesized in Example 1 and Example 5. In the figure, the Ni single atoms synthesized by two types of carbon black only have the peak of carbon black, and no peak of metal element or compound appears. This indicates that the type of carbon black has no significant effect on the formation of single-atom catalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com