Online monitoring method of laser additive manufacturing process based on multi-source heterogeneous data

A multi-source heterogeneous data and manufacturing process technology, applied in the direction of additive processing, electrical digital data processing, special data processing applications, etc., can solve problems such as easy spheroidization, no longer applicable, lack of process control of forming quality, etc. , to achieve the effect of solving deep learning and fusion and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In this embodiment, an online monitoring method of laser additive manufacturing process based on multi-source heterogeneous data is carried out as follows:

[0043] In the selective laser melting process, laser light interacts with metal powders to produce a process of melting, vaporization and reconstruction. There are many signal sources in this laser melting process, including acoustic signals, plasma signals, ultrasonic waves, infrared radiation and electrical signals. The formation and change of these signals are closely related to the formation and change of the molten pool. The study of the sound, temperature, image formation and change mechanism in the laser melting process is of great significance for revealing the thermodynamic laws of the laser melting process.

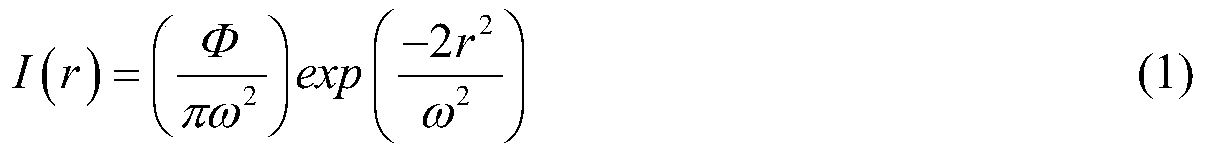

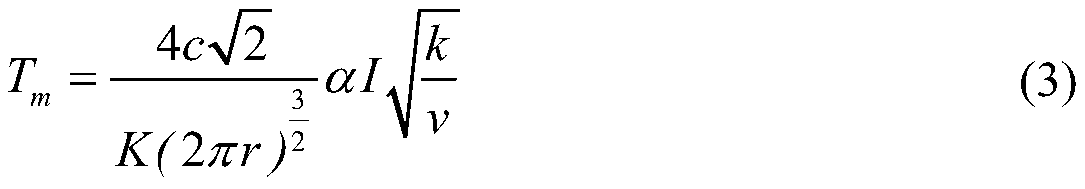

[0044] Study the sound, temperature, image formation and change mechanism in the laser melting process, establish the laser energy distribution when the laser adopts Gaussian distribution, and establ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com