Composite self-lubricating layer prepared by extrusion water spraying method and preparation method thereof

A technology of self-lubricating layer and composite belt, applied in the direction of coating, etc., can solve the problems of inapplicability, achieve the effect of prolonging the service life, good wear resistance and fatigue resistance, and simplifying the process and steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

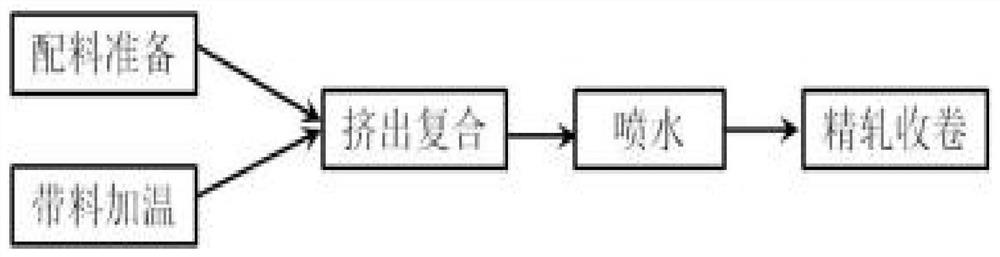

Method used

Image

Examples

Embodiment 1

[0065] Preparation of PEEK composite self-lubricating layer

[0066] A weight percentage of the polyether ether ketone 65%, 12% PTFE, 12% carbon fiber, 11% graphite mixed, dried at 130 ℃ under give mix, the mix into the extruder ;

[0067] Powder discharged from the ball strip Unwinder, the system enters the preheating (preheating frequency induction) preheated at 250 deg.] C, to give the powder strip preheated pellets; then passes under the discharge opening extruded, ready to enter the rolling mill; et extrusion mixture after the cover strip into the rolling mill driven by a recombination process;

[0068] The mixture was heated to 370 deg.] C in, until the mixture reaches a half molten state, self-lubricating layer extruded film 1mm thick;

[0069] The self-lubricating-layer film of the blanket to preheat the powder strip on the ball, at 260 ℃ (electric wire temperature) at 1m / min rate of rolling to obtain a composite strip;

[0070] Cooling the composite under conditions tap...

Embodiment 2

[0074] Preparation of polyetheretherketone self-lubricating layer

[0075] A weight percentage of 70% polyether ether ketone, a polyphenylene ester 10%, 10% aramid, 10% molybdenum disulfide, mixed, dried at 130 ℃ under give mix, pressing the mix into the machine;

[0076] Powder discharged from the ball strip Unwinder into preheating system (high-frequency induction preheating) preheated at 365 deg.] C, to give the powder strip preheated pellets; then passes under the discharge opening extruded, ready to enter the rolling mill, mix, etc. after extrusion self-lubricating-layer film covered by the strip entering the rolling mill driven recombination process;

[0077] The mixture was heated to 415 deg.] C in, until the mixture reaches a half molten state, self-lubricating layer extruded film of a thickness of 0.05mm;

[0078] The self-lubricating-layer film of the blanket to preheat the powder strip on the ball, at 315 deg.] C (outside temperature infrared ray) at 3m / min rate of ro...

Embodiment 3

[0083] Preparation of polyetheretherketone self-lubricating layer

[0084] A weight percentage of 50% polyether ether ketone, 20% polytetrafluoroethylene, 18% glass fiber, 12% graphite fluoride, mixed, dried at 130 ℃ under give mix, the mix into extruder;

[0085] Powder discharged from the ball strip Unwinder, the system enters the preheating (preheating infrared radiation) preheated at 300 ℃, to give spherical powder preheated strip, then passes under the discharge opening extruded, ready to enter the rolling mill, extruding the mixture, etc. after the film layer is covered by the lubricating strip entering the rolling mill driven by a recombination process;

[0086] After the mixture was heated to 400 ℃, until the mixture reaches a half molten state, extruded from a 10mm thick lubricating layer film;

[0087] The self-lubricating-layer film of the blanket to preheat the powder strip on the ball, (transfer temperature heating belt) at 300 deg.] C at 10m / min rate of rolling to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com