A kind of ultra-high-strength concrete and thin-walled electric pole made of the ultra-high-strength concrete

An ultra-high-strength concrete, thin-walled technology, applied in the field of building materials, can solve the problems of inconvenient transportation, installation and maintenance, large bearing capacity wall thickness, and cracking damage of electric poles, and achieves easy transportation, installation and maintenance, and low porosity. , The effect of reducing the weight of the pole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

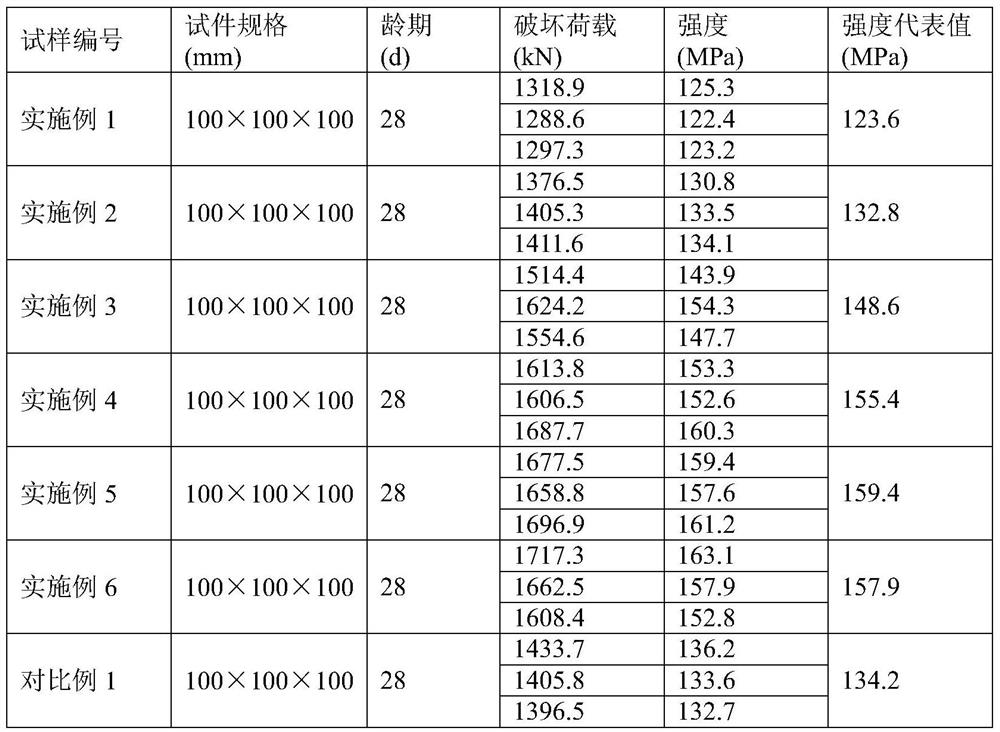

Examples

Embodiment 1

[0031] P.O 52.5 Ordinary Portland Cement 1000kg, SiO 2 The content is 95% and the specific surface area is 20000m 2 200kg of silica fume / kg, 1200kg of 4-mesh quartz sand, 218kg of wavy 30mm steel fiber are fully mixed in a concrete mixer; then 223kg of water is added and fully stirred for 30min; The water agent is fully stirred until the mixture is uniform, and the ultra-high-strength concrete is obtained after being discharged from the tank. The ultra-high-strength concrete is centrifugally formed to produce a thin-walled electric pole with a wall thickness of 40mm.

Embodiment 2

[0033] P.O 52.5 Ordinary Portland Cement 1000kg, SiO 2 The content is 95% and the specific surface area is 20000m 2 200kg of silica fume / kg, 1627kg of 4-mesh quartz sand, and 236kg of wavy 30mm steel fibers are fully mixed in a concrete mixer; then 235kg of water is added and fully stirred for 30min; The water agent is fully stirred until the mixture is uniform, and the ultra-high-strength concrete is obtained after being discharged from the tank. The ultra-high-strength concrete is centrifugally formed to produce a thin-walled electric pole with a wall thickness of 39mm.

Embodiment 3

[0035] P.O 52.5 Ordinary Portland Cement 1000kg, SiO 2 The content is 95% and the specific surface area is 20000m 2 187kg of silica fume / kg, 1490kg of 4-mesh quartz sand, and 217kg of wavy 30mm steel fiber are fully mixed in a concrete mixer; then 184kg of water is added and fully stirred for 30min; The water agent is fully stirred until the mixture is uniform, and the ultra-high-strength concrete is obtained after being discharged from the tank. The ultra-high-strength concrete is centrifugally formed to produce a thin-walled electric pole with a wall thickness of 37mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com