Anti-doodling fluorescent water paint for interior wall and preparation method of water paint

An anti-graffiti and fluorescent technology, applied in the field of coatings, to achieve the effects of good stain resistance, excellent anti-mold and antibacterial performance, and strong fluorescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

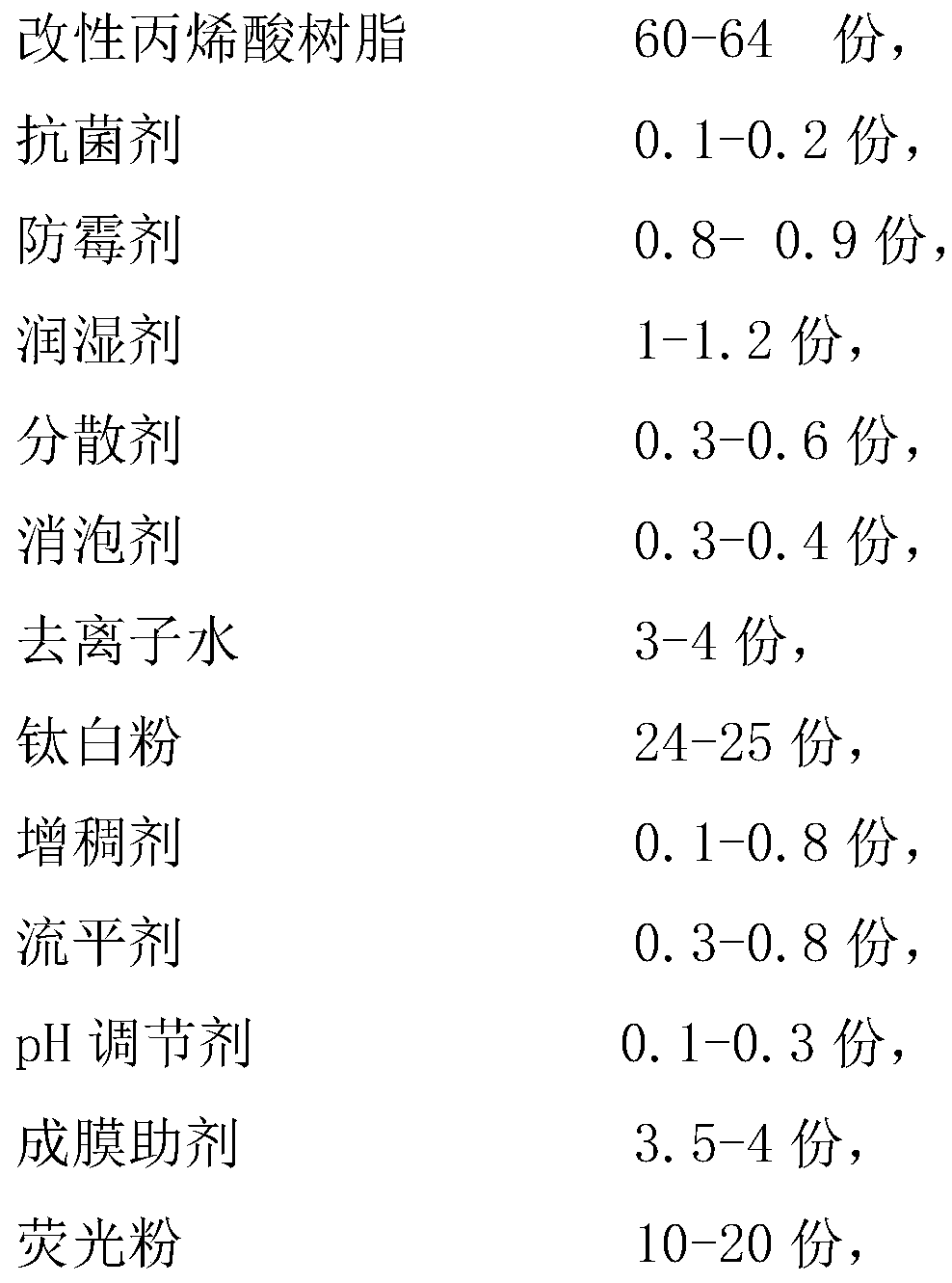

[0029] Fluorescent anti-graffiti interior wall water paint provided by the invention comprises the following components by weight fraction:

[0030] Described finished paint comprises:

[0031]

[0032] The following components of the curing agent in parts by weight:

[0033] 7.5 parts of modified aliphatic polyisocyanate,

[0034] 2 parts of organic solvent.

[0035] The organosiloxane-modified waterborne hydroxyl polyacrylic resin described in this example is a kind of polyacrylic acid, methacrylic acid, methyl methacrylate, butyl acrylate and multifunctional auxiliary agent produced by Hebei Xinguang Chemical Co., Ltd. Copolymerized emulsion with optimized process. The dispersant is BYK-190 from BYK. The defoamer is BASF's A10. The titanium dioxide is Lomon LR996. The leveling agent is BYK-346 from BYK. The film-forming aid is TEXANOL of Qilu Eastman Specialty Chemicals Co., Ltd. The pH regulator is selected from Dow Chemical's AMP-95.

[0036] The preparation m...

Embodiment 2

[0047] The difference between embodiment 2 and embodiment 1 is that

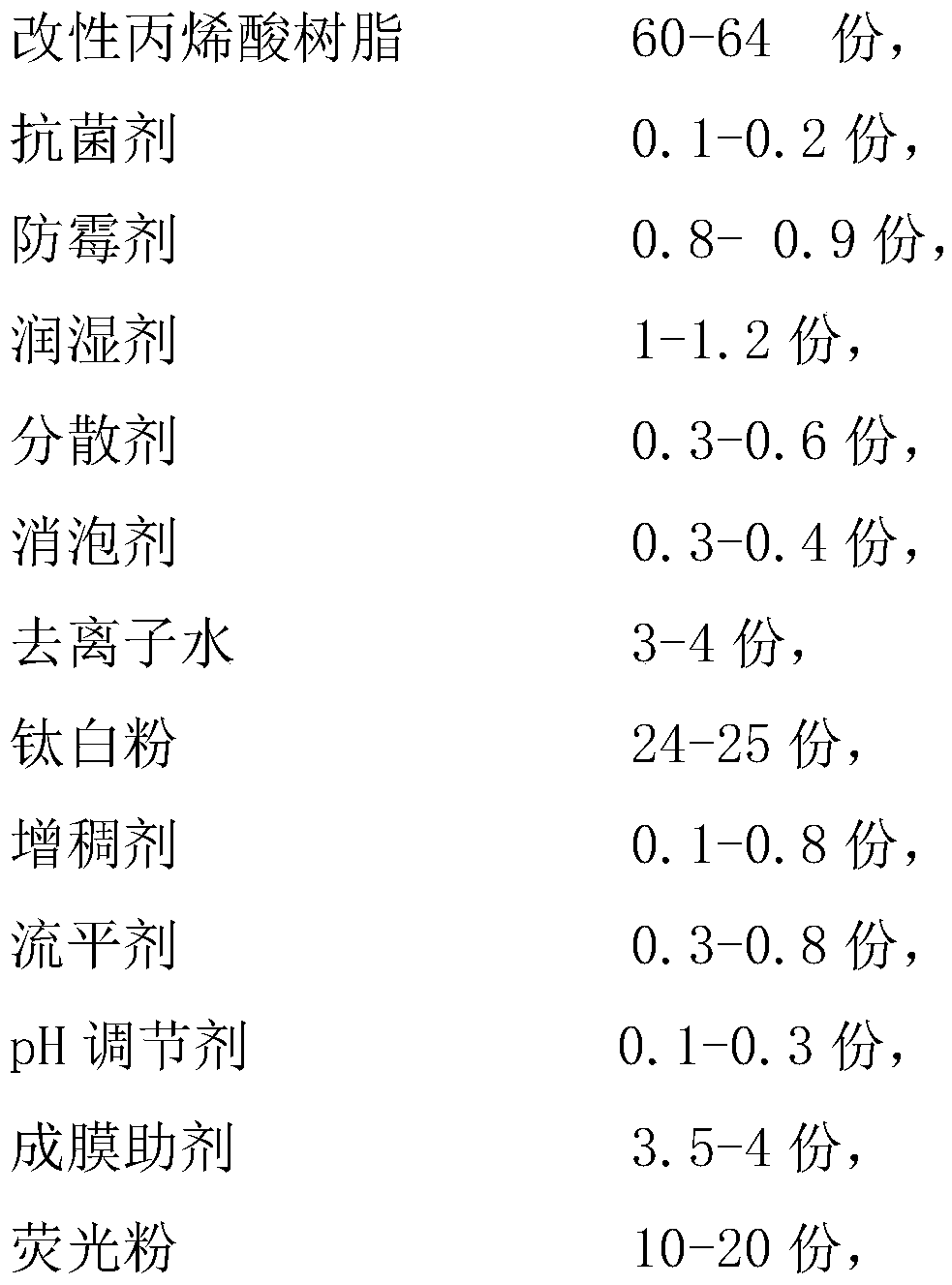

[0048] The invention provides fluorescent anti-graffiti interior wall water paint, which comprises the following components by weight fraction:

[0049] Described finished paint comprises:

[0050]

[0051] Described curing agent comprises:

[0052] 8.5 parts of modified aliphatic polyisocyanate,

[0053] 3 parts of organic solvent.

[0054] The thickener is an alkali-swellable thickener. The wetting agent is polyacrylate.

[0055] The preparation method of acrylic acid amino stoving varnish of the present invention, comprises the steps:

[0056] (1) Add the modified acrylic resin to the reaction tank A, stir at a speed of 200-300rpm for 2-3 minutes, then add deionized water, pH regulator, wetting agent, dispersant, defoamer, antibacterial agent, Coalescing aid, stir at a speed of 400-600rpm until uniform;

[0057] (2) Slowly add titanium dioxide, fluorescent powder, and deionized water into the re...

Embodiment 3

[0065] The difference between embodiment 3 and embodiment 1 is:

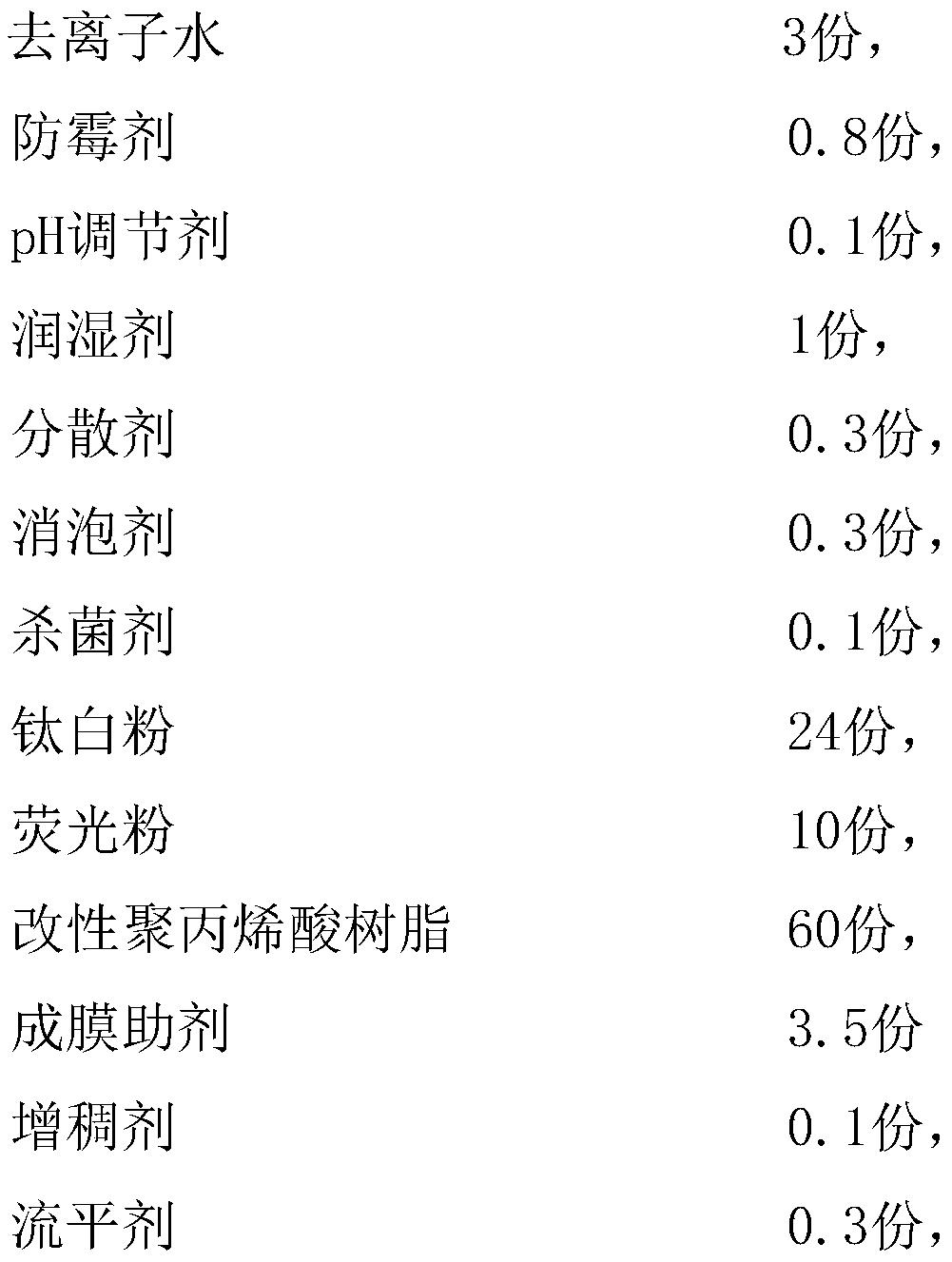

[0066] The invention provides fluorescent anti-graffiti interior wall water paint, which comprises the following components in parts by mass:

[0067] Described finished paint comprises:

[0068]

[0069] Described curing agent comprises:

[0070] 8 parts of modified aliphatic polyisocyanate,

[0071] 2.5 parts of organic solvent.

[0072] The preparation method of anti-graffiti interior wall paint of the present invention, comprises the steps:

[0073] (1) Add the modified acrylic resin to the reaction tank A, stir at a speed of 200-300rpm for 2-3 minutes, then add deionized water, pH regulator, wetting agent, dispersant, defoamer, antibacterial agent, Coalescing aid, stir at a speed of 400-600rpm until uniform;

[0074] (2) Slowly add titanium dioxide, fluorescent powder, and deionized water into the reaction tank A, stir at a speed of 1200-1300rpm for 30 minutes, stop the machine, and test the finenes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com