A kind of acid cleaning fracturing fluid and preparation method thereof

A clean fracturing fluid and acidic technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of limited formation acidification capacity, heavy fluid mixing workload, high cost, etc., and achieve good sand-carrying performance and acidification The effect of strong ability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

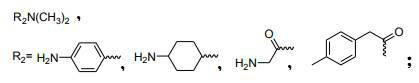

[0027] Molar ratio: stearic acid: erucic acid: 2-amino-N,N-dimethylacetamide: KF / γ-Al 2 o 3 =1:2:1:0.3, stearic acid: erucic acid: l,3-dichloro-2-propanol = 1:2:3 Prepare raw materials, mixed solvent is V 乙醇 :V 水 =1:1.

[0028] Add stearic acid, erucic acid, 2-amino-N,N-dimethylacetamide and KF / γ-Al 2 o 3 , stirring and raising the temperature to 90° C., maintaining the temperature for 8 hours, and cooling to room temperature to obtain an intermediate. Mix the intermediate and 1,3-dichloro-2-propanol in a mixed solvent evenly, stir and heat up to 70°C, keep the temperature for 6 hours, cool to room temperature, and the obtained reddish-brown liquid is the gemini surfactant of the present invention .

[0029] The acidic cleaning fracturing fluid Y1 is obtained by mixing and stirring according to the following proportions, and each component is calculated by mass percentage: 0.8% of the gemini surfactant of the present invention, 20% of hydrochloric acid, and the rest is...

Embodiment 2

[0031] Molar ratio: palmitic acid: erucic acid: 4-amino-N,N-dimethylaniline: K / γ-Al 2 o 3 = 1:1:1:0.1, palmitic acid: erucic acid: l,3-dibromo-2-propanol = 1:1:2 Prepare raw materials, mixed solvent is V 异丙醇 :V 水 =1:1.5.

[0032] Add palmitic acid, erucic acid, 4-amino-N,N-dimethylaniline and K / γ-Al 2 o 3 , stirring and raising the temperature to 110° C., maintaining the temperature for 10 hours, and cooling to room temperature to obtain an intermediate. Mix the intermediate and 1,3-dibromo-2-propanol in a mixed solvent evenly, stir and heat up to 80°C, keep the temperature for 8 hours, cool to room temperature, and the obtained reddish-brown liquid is the gemini surfactant of the present invention .

[0033] The acidic cleaning fracturing fluid Y2 is obtained by mixing and stirring according to the following proportions, and the components are expressed in mass percent: 0.5% of the gemini surfactant of the present invention, 20% of hydrochloric acid, and the rest is w...

Embodiment 3

[0035] Molar ratio: benzoic acid: oleic acid: 4-methyl-N,N-dimethylphenylacetamide: KCO 3 / γ-Al 2 o 3 = 1:2:1:0.3, benzoic acid: oleic acid: 1,3-dibromo-2-propanol = 1:2:4 Prepare raw materials, mixed solvent is V 乙醇 :V 水 =1.5:1.

[0036] In the reaction kettle equipped with electric stirrer, condenser, thermometer and oil bath heating condition, add benzoic acid, oleic acid, 4-methyl-N,N-dimethylphenylacetamide and KCO 3 / γ-Al 2 o 3, stirring and raising the temperature to 100° C., maintaining the temperature for 12 hours, and cooling to room temperature to obtain an intermediate. Mix the intermediate and 1,3-dibromo-2-propanol in a mixed solvent evenly, stir and raise the temperature to 60°C, keep the temperature for 12 hours, cool to room temperature, and the obtained reddish-brown liquid is the gemini surfactant of the present invention .

[0037] The acidic cleaning fracturing fluid Y3 is obtained by mixing and stirring according to the following proportions, eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com