Preparation method of anti-pollution polyamide film composite film

A polyamide thin film, composite membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of reducing the feasibility of large-scale production and application, increasing the preparation cost, complex steps, etc. The effect of membrane fouling flux attenuation rate reduction, easy large-scale industrial production, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing an anti-pollution polyamide film composite reverse osmosis membrane (RO), the specific steps are as follows:

[0032] 1. Prepare an aqueous monomer solution containing calcium ions: respectively select m-phenylenediamine (MPD) and anhydrous calcium chloride as the aqueous film-forming monomer and water-soluble calcium salt, and mix m-phenylenediamine (MPD) and Anhydrous calcium chloride was added to water, and then stirred continuously under constant temperature (25° C.) until completely dissolved to obtain a mixed solution. The concentration of MPD in the solution was 3.0 wt%, CaCl 2 The concentration is 1.0wt%;

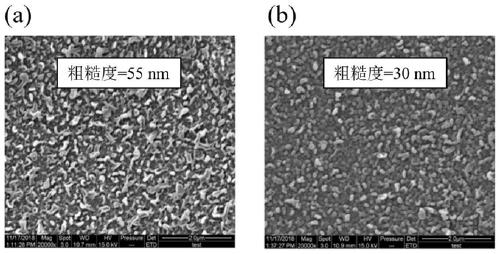

[0033]2. Interfacial polymerization: The surface of the porous flat ultrafiltration membrane with a molecular weight cut-off of 150,000 Daltons prepared by polysulfone material is immersed in the aqueous phase monomer solution containing calcium ions prepared in step 1, soaked for 2 minutes, and then used The a...

Embodiment 2

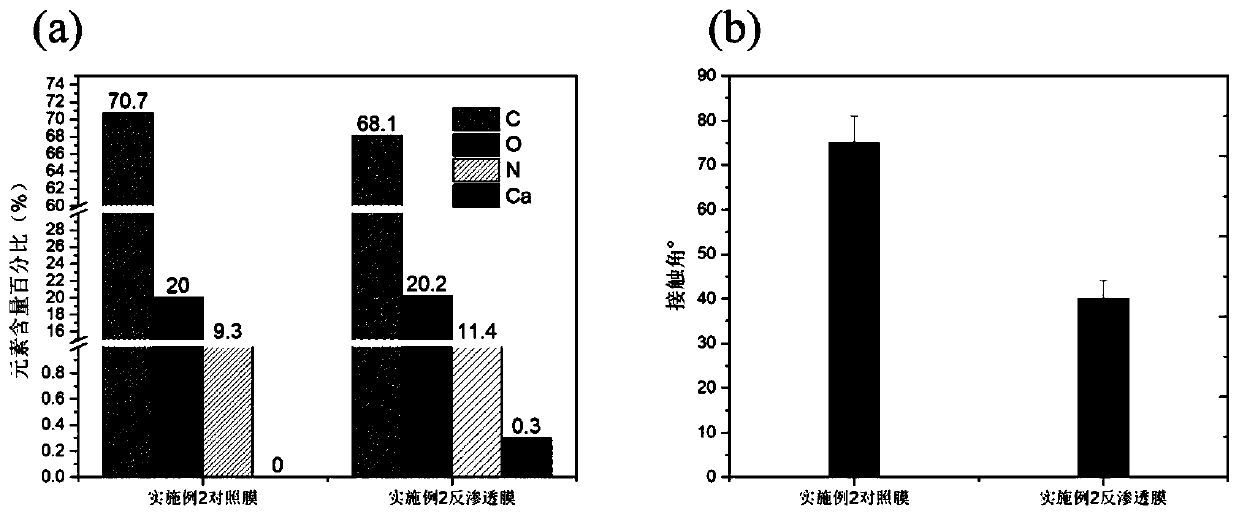

[0038] This embodiment provides another preparation method of anti-pollution polyamide film composite reverse osmosis membrane (RO), the specific steps are as follows:

[0039] 1. Preparation of aqueous monomer solution containing calcium ions: respectively select p-phenylenediamine (PPD) and anhydrous calcium iodide as aqueous film-forming monomer and water-soluble calcium salt, add PPD and anhydrous calcium iodide into water, then continuously stirred under constant temperature until completely dissolved to obtain a mixed solution, the concentration of PPD in the solution is 2.0wt%, CaI 2 The concentration is 0.4wt%;

[0040] 2. Interfacial polymerization: immerse the surface of a porous flat ultrafiltration membrane with a molecular weight cut-off of 100,000 Daltons prepared from polyethersulfone material in the aqueous monomer solution containing calcium ions prepared in step 1, soak for 1 min, and then Use an air knife to remove visible liquid droplets on the surface of ...

Embodiment 3

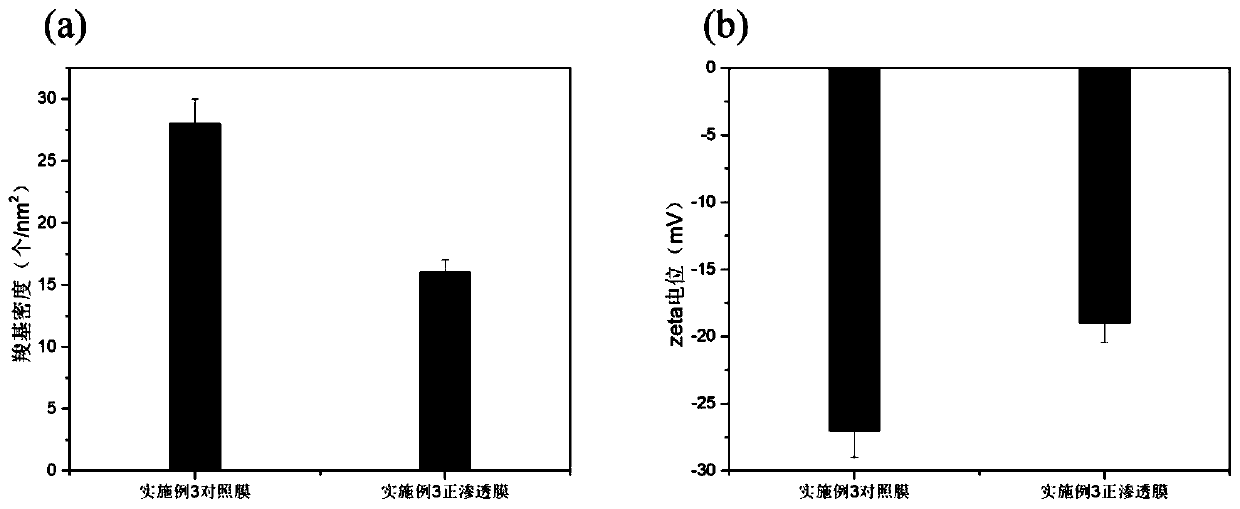

[0045] Different from specific examples 1 and 2, this example provides a method for preparing an anti-pollution polyamide film composite forward osmosis membrane, and the specific steps are as follows:

[0046] 1. First prepare a polysulfone porous support membrane without a non-woven fabric layer: mix the film-forming polymer polysulfone with a molecular weight of 140,000 to 150,000 Daltons, additives and solvents, stir for 24 hours under sealed conditions, and then Place the defoaming naturally under sealed conditions for 16 hours to obtain the polysulfone casting solution, and then prepare the polysulfone casting solution into a support layer in the form of a flat plate by a non-solvent-induced phase inversion method, wherein the thickness of the scraping film is controlled to be 100 microns; The solvent is N-methylpyrrolidone, and the additive is ethylene glycol; the mass fraction of polysulfone in the polysulfone casting solution is 15wt%, and the concentration of ethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com