A heat of hydration inhibiting concrete anticorrosion rust inhibitor and its preparation method and application

A hydration heat suppression and concrete technology, applied in the field of concrete admixtures, can solve the problems of not being able to resist sulfate erosion on concrete at the same time, not being able to well control early temperature shrinkage cracks, reinforced concrete structure damage, etc., and reducing the early stage of concrete. The total amount of hydration and heat release, the effect of increasing anti-corrosion and rust resistance, and the effect of alleviating damage

Active Publication Date: 2021-06-11

WUHAN YUANJIN BUILDING MATERIALS TECH CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, it does not have the function of inhibiting the heat of hydration in the early stage of concrete, cannot well control the generation of early temperature shrinkage cracks, and cannot resist the erosion of sulfate on concrete at the same time. In land areas, reinforced concrete structures remain vulnerable to damage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0027] Citric Acid 1.2%

[0028] Ammonium heptamolybdate 0.5%

[0029] Sodium hexametaphosphate 0.2%

[0030] Anhydrite 98.1%

Embodiment 2

[0032] Tartaric acid 1.2%

[0033] Ammonium heptamolybdate 0.6%

[0034] Sodium hexametaphosphate 0.2%

[0035] Anhydrite 98%

Embodiment 3

[0037] Sorbitol 2%

[0038] Ammonium heptamolybdate 0.8%

[0039] Sodium hexametaphosphate 0.2%

[0040] Anhydrite 97%

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

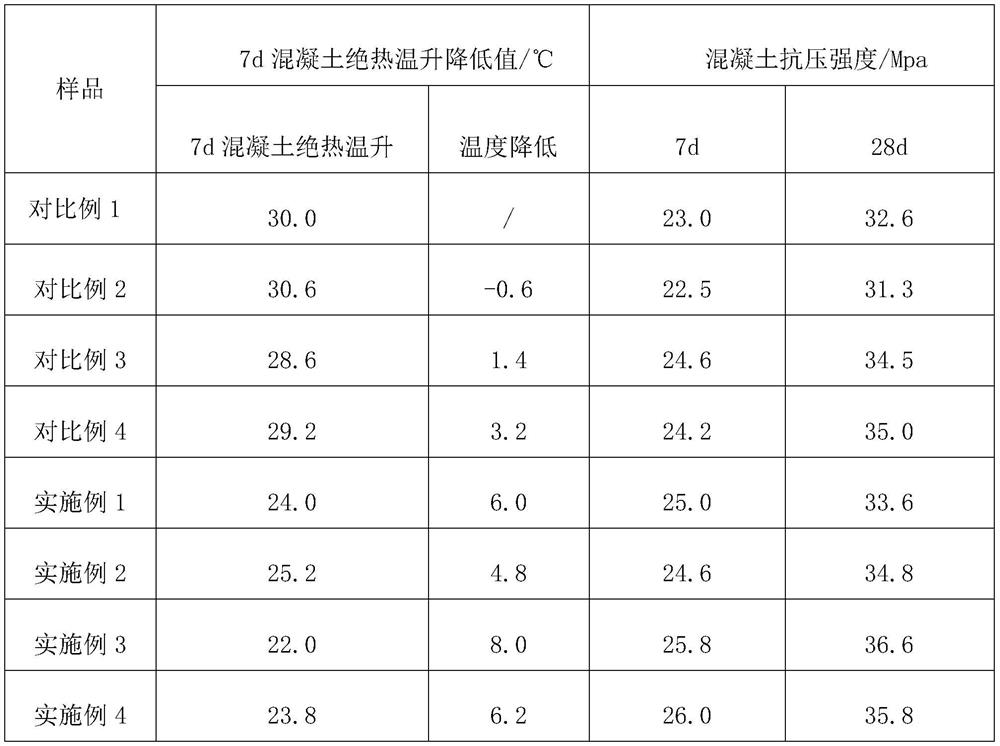

The invention discloses a heat of hydration inhibiting concrete anticorrosion and rust inhibitor and its preparation method and application. The anticorrosion and rust inhibitor is made of the following raw materials in mass percentage: 1% to 3% of hydration heat inhibiting components, Ammonium heptamolybdate 0.5% to 1%, sodium hexametaphosphate 0.2% to 1%, gypsum 95% to 99%. The anti-corrosion and rust inhibitor can be mixed into concrete to resist the corrosion of sulfate and chloride ions to concrete. The preparation method of the present invention is simple, and only needs to mix several raw materials evenly. The prepared anti-corrosion and rust inhibitor has The following advantages: It can significantly reduce the early hydration rate and heat of hydration of cement, thereby reducing the internal hydration temperature rise of concrete and reducing early temperature shrinkage cracks; it can improve the ability of concrete to resist sulfate and chloride ion erosion, and form passivation on the surface of steel bars film, which plays an active role in rust prevention. It can be widely used in large-volume concrete structures in sulphate and chloride corrosion environments.

Description

technical field [0001] The invention belongs to the technical field of concrete admixtures, and in particular relates to a hydration heat-inhibiting concrete anticorrosion and rust inhibitor as well as a preparation method and application thereof. Background technique [0002] In recent years, the durability of reinforced concrete structures has become a worldwide concern. Coastal ports and saline soil areas usually contain a large amount of sulfate and chloride salts, which have a serious erosive effect on concrete and steel bars, causing serious damage to reinforced concrete structures and seriously affecting their service life. The existing traditional anti-corrosion method uses a certain amount of mineral admixtures in the concrete to improve the compactness of the cement and reduce the salt corrosion stress, but the effect of this method is limited. The use of rust inhibitors to delay the corrosion of steel bars is an important measure to improve the durability of rein...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B24/06C04B24/02C04B103/61

Inventor 纪宪坤刘燕李新新张小平李磊侯维红

Owner WUHAN YUANJIN BUILDING MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com