Low-odor and high-toughness ultraviolet curing adhesive and preparation method thereof

A high-toughness, ultraviolet light technology, used in adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of skin irritation, poor toughness, strong odor, etc., and achieve low odor and high toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

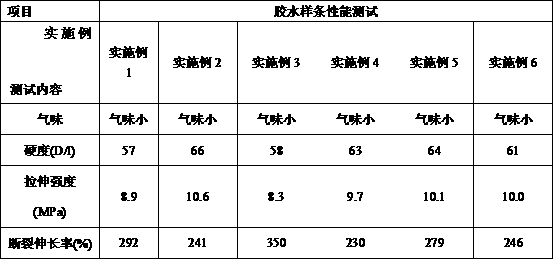

Examples

Embodiment 1

[0023] A low-odor, high-toughness UV-curable adhesive. In terms of weight percentage, the raw materials are: 36% acrylic modified polyurethane resin, 43% acrylic monomer diluent, 14% toughening monomer, and 3% photoinitiator , 3% silane coupling agent, 0.1% inhibitor, 0.5% defoamer, 0.4% wetting agent.

[0024] The preparation method of above-mentioned a kind of low smell, high tenacity ultraviolet curing adhesive, it comprises the following steps:

[0025] (1) Weigh acrylic modified polyurethane resin and acrylic monomer diluent in the reaction kettle according to the proportion of the formula, and stir for 2-3 hours in the dark at a speed of 150-300 r / min to obtain a uniform dispersion liquid;

[0026] (2) Add silane coupling agent, polymerization inhibitor and other additives in proportion, rotate at 150-300 r / min, and continue to stir for 30 minutes;

[0027] (3) Add equal proportions of photoinitiators in batches, with a rotation speed of 150-300 r / min, and gradually inc...

Embodiment 2

[0032] A low-odor, high-toughness UV-curable adhesive. In terms of weight percentage, the raw materials are: 30% acrylic modified polyurethane resin, 45% acrylic monomer diluent, 20% toughening monomer, and 2% photoinitiator , 3% silane coupling agent.

[0033] The preparation method and steps of the above-mentioned examples are the same as those in Example 1.

Embodiment 3

[0035] A low-odor, high-toughness UV-curable adhesive. In terms of weight percentage, the raw materials are: 37% acrylic modified polyurethane resin, 37% acrylic monomer diluent, 20% toughening monomer, and 2% photoinitiator , 3% silane coupling agent, 0.5% defoamer, 0.5% wetting agent.

[0036] The preparation method and steps of the above-mentioned examples are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com