Pipeline dredging robot

A robot and pipeline technology, applied in the field of pipeline dredging, can solve problems such as easy to be blocked, unstable work, excessive sewage flow, etc., and achieve the effect of preventing internal blockage, reducing labor intensity, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

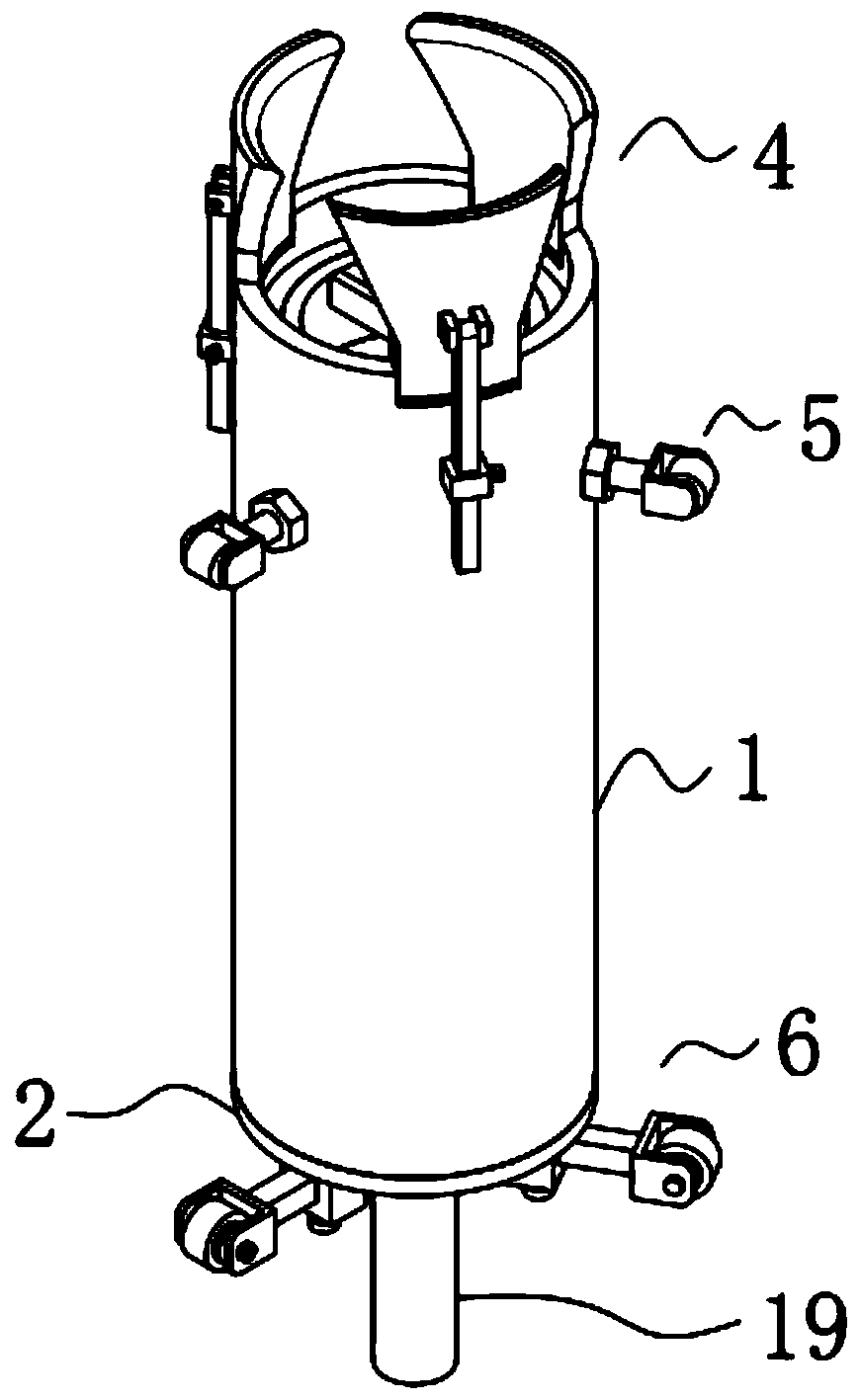

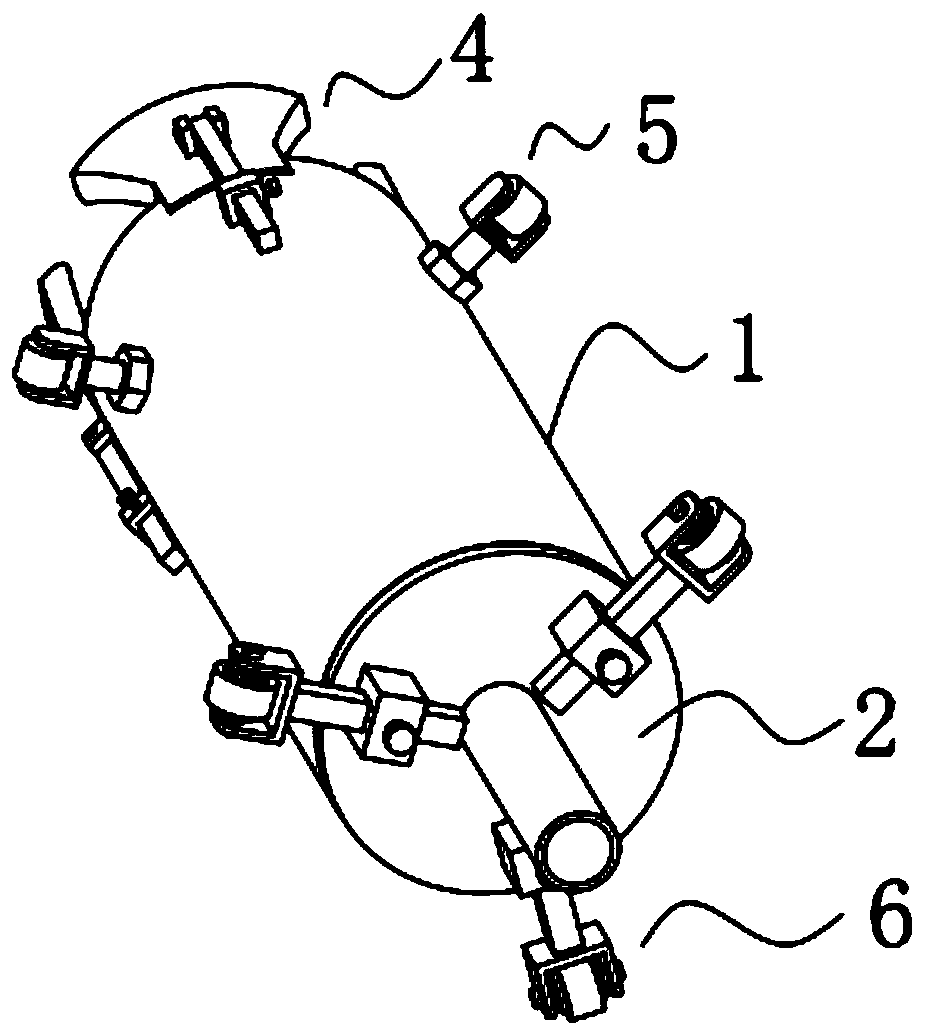

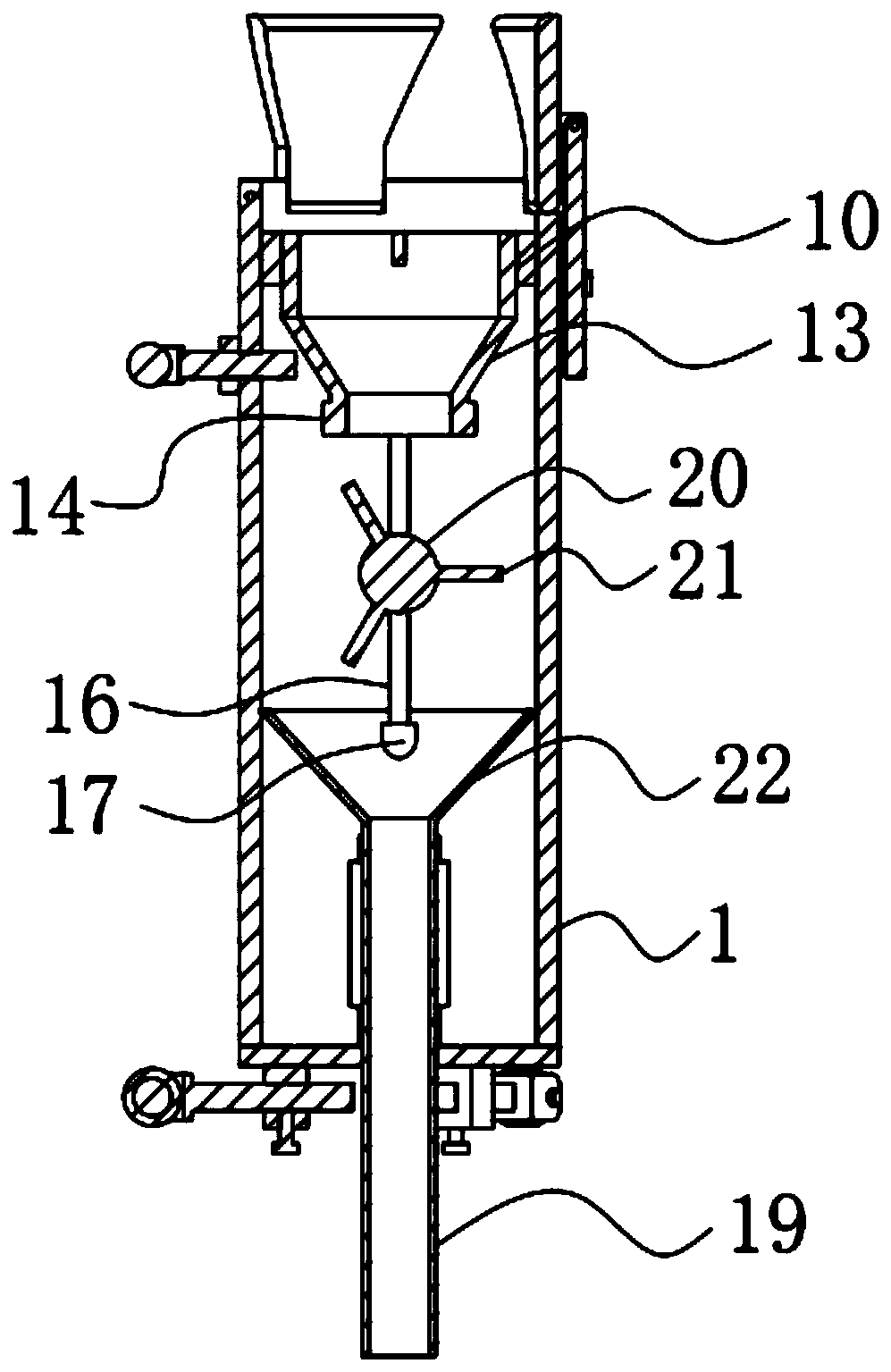

[0055] A pipeline dredging robot, such as Figure 1-2 As shown, it includes a cylindrical shell 1, the upper end of the cylindrical shell 1 is evenly provided with at least three sets of scraper assemblies 4, and the bottom end of the cylindrical shell 1 is fixedly equipped with an end cover 2, the cylindrical shell 1 At least three sets of support assemblies 5 are evenly provided on the outer surface of the outer surface near its upper end, and at least three sets of crawling assemblies 6 are evenly provided on the side of the end cover 2 away from the cylindrical shell 1. A crushing assembly 18 is provided inside the casing 1 near its upper end, and a sludge discharge assembly 3 is provided inside the cylindrical casing 1 near the crushing assembly 18 .

[0056] By adopting the above-mentioned technical scheme, the scraper assembly 4 is used to scrape off the dirt on the inner wall of the pipeline that needs to be cleaned; the crushing assembly 18 is used to crush the dirt s...

Embodiment 2

[0077] The difference from Embodiment 1 is that the surfaces of the first brushless motor 38, the second brushless motor 20 and the drive motor 12 are all provided with a protective layer, and the protective layer is prepared by the following method:

[0078] Take the following raw materials and weigh them by weight: 25 parts of epoxy resin, 10 parts of calcium carbonate powder, 25 parts of acrylic emulsion, 10 parts of quartz powder, 12 parts of polyurethane, 10 parts of asphalt, 3 parts of alcohol ester twelve, 2 parts of emulsified silicone oil , 20 parts of triethanolamine and 20 parts of water;

[0079] S1. Add the weighed acrylic emulsion, asphalt, alcohol ester dodeca, triethanolamine, emulsified silicone oil and ethanol into the mixer and stir for 20min at a stirring speed of 600r / min to prepare a mixed solution;

[0080] S2, adding epoxy resin, calcium carbonate powder, quartz powder and polyurethane into a pulverizer for pulverization until the particle diameter of t...

Embodiment 3

[0086] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0087] Take the following raw materials and weigh them by weight: 30 parts of epoxy resin, 12 parts of calcium carbonate powder, 30 parts of acrylic emulsion, 12 parts of quartz powder, 14 parts of polyurethane, 11 parts of asphalt, 4 parts of alcohol ester twelve, 3 parts of emulsified silicone oil , 25 parts of triethanolamine and 25 parts of water;

[0088] S1. Add the weighed acrylic emulsion, asphalt, alcohol ester dodeca, triethanolamine, emulsified silicone oil and ethanol into the mixer and stir for 25min at a stirring speed of 750r / min to prepare a mixed solution;

[0089] S2, adding epoxy resin, calcium carbonate powder, quartz powder and polyurethane into a pulverizer for pulverization until the particle diameter of the material is not greater than 200nm to obtain a mixed powder material;

[0090] S3. Add the mixed solution prepared i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com