A kind of flexible transparent conductive film with hierarchical structure and preparation method thereof

A kind of technology of transparent conductive film and hierarchical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

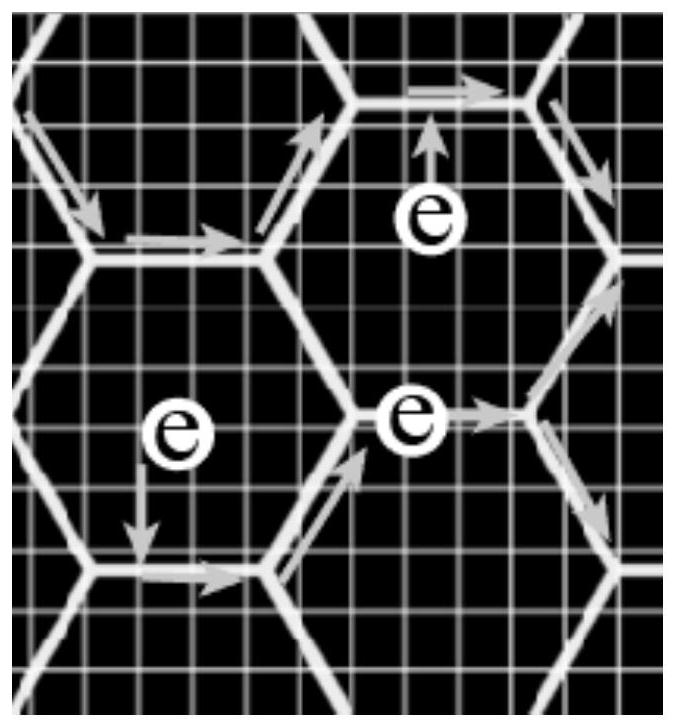

[0031] A method for preparing a flexible transparent conductive film with a hierarchical structure provided by an embodiment of the present invention includes the following steps:

[0032] S1, using electrospinning to obtain a three-dimensional network polymer template.

[0033] Further, in a preferred embodiment of the present invention, the spinning solution for electrospinning is a PVA colloid solution with a mass concentration of 5-20%.

[0034] In a preferred embodiment, the process of electrospinning is as follows: the aluminum groove is used as a collector, a positive voltage of 12-18 kV is applied to the emitter, and a negative voltage of 1-3 kV is applied to the collector. ~20% PVA colloidal solution is the spinning solution, and the polymer template with three-dimensional network structure is obtained by spinning.

[0035] Preferably, the preparation process of the aluminum groove is as follows: folding the thickened aluminum foil into a groove with a width of 2-10 ...

Embodiment 1

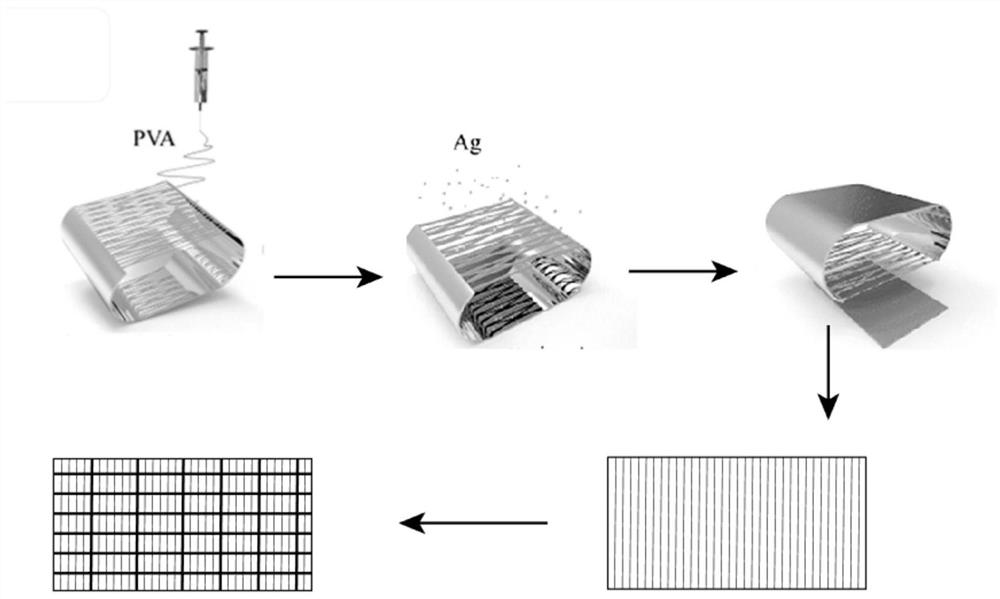

[0059] A flexible transparent conductive film with a hierarchical structure provided in this embodiment is prepared according to the following steps, as figure 2 Shown is a schematic diagram of the preparation process of the flexible transparent conductive film:

[0060] (1) The PET film with a thickness of 50 μm was washed with deionized water and absolute ethanol for 30 min, and dried as a flexible and clear substrate for future use.

[0061] (2) Three-dimensional PVA nanofiber network was prepared under the conditions of positive voltage 15kV and negative voltage 2kV by electrospinning method, and the spinning solution was PVA colloidal solution with a mass concentration of 10%.

[0062] (3) The PVA nanofiber network is placed in a magnetron sputtering apparatus to sputter metallic silver with a vacuum of 1×10 -5 Pa, the flow rate of high-purity argon is 50cm 3 / min, the distance between the target and the substrate is 6cm, the deposition beam is incident perpendicular t...

Embodiment 2

[0069] This implementation is basically the same as that of Example 1, except that in step (3), the sputtered metal is copper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com