Conductive silver paste and preparation method thereof

A technology of conductive silver paste and silver powder, which is used in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of loss of activity, low thixotropic index of silver paste, and low production efficiency, etc. Achieve the effect of improving thixotropic index, shortening production cycle and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

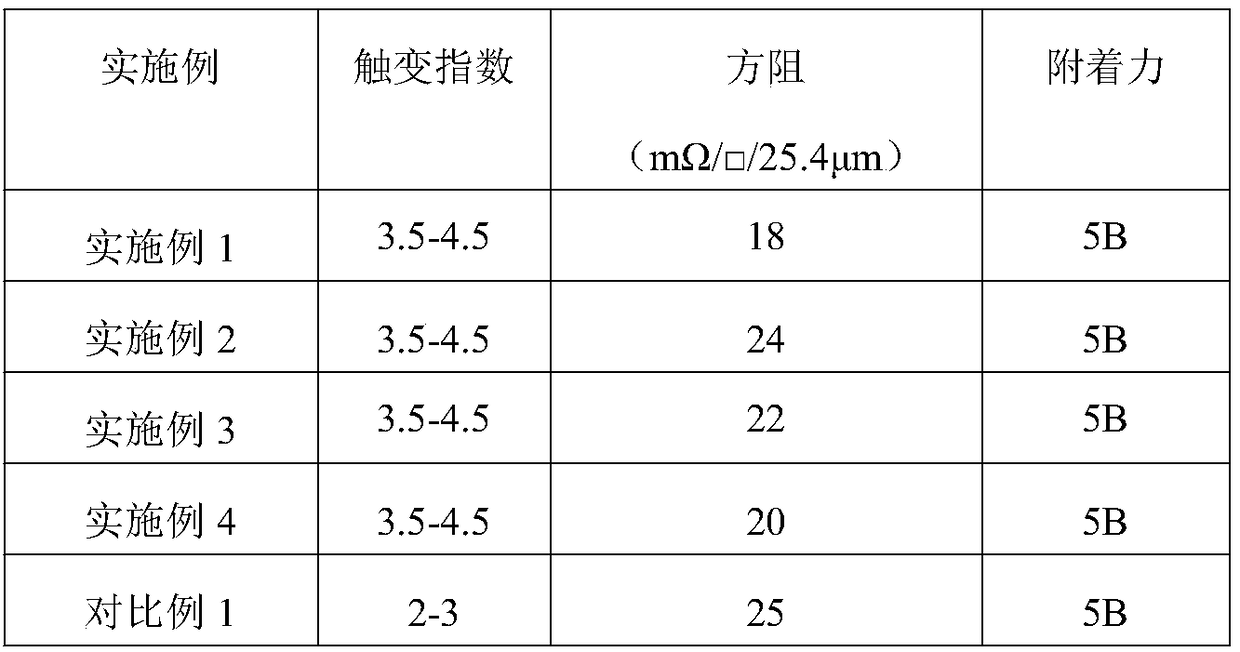

Examples

preparation example Construction

[0029] Preparation of silver powder

[0030] Dissolve 32Kg of silver nitrate in 300L of deionized water at 40°C under stirring to prepare a silver nitrate aqueous solution, add 3Kg of oleic acid dispersant, mix thoroughly under stirring, and disperse with ultrasonic to obtain a silver salt solution.

[0031] Dissolve 10Kg of sodium hydroxide in 100L of deionized water at 25°C under agitation. It is sufficient to completely dissolve the sodium hydroxide to prepare an aqueous solution of sodium hydroxide.

[0032] Dissolve 10Kg of sodium borohydride in 1000L of deionized water at about 25°C with stirring to obtain a reducing agent solution.

[0033] Fully dissolve 3Kg of hydroxymethylcellulose in 20L of deionized water at about 25°C under stirring conditions to obtain a sedimentation agent solution.

[0034] Under the condition of constant stirring, slowly add the aqueous sodium hydroxide solution into the silver salt solution until the pH value of the solution is equal to 9, s...

Embodiment 1

[0038] A conductive silver paste, its composition and percentage by weight are: 80% silver powder, 15% organic vehicle, 3.5% activated polyamide wax powder, 0.5% simethicone, 0.5% oleic acid, 0.5% BYK-110.

[0039] 1) Organic carrier preparation: take by weighing 10% DBE of the total mass of organic resin and organic solvent, 60% diethylene glycol ethyl ether acetate, 10% dibutyl phthalate, 13% maleic acid resin , 6% of polyphenolic resin, 0.7% of rosin, 0.3% of organic silicon resin are added in the double planetary power mixer mixer with a constant temperature water bath, and the temperature of the water bath is adjusted to be 65°C, and the stirring speed is 800rpm. Mixing 2h, pass through a 200-mesh stainless steel sieve while it is hot, and import it into the transfer barrel;

[0040]2) Thixotropic agent activation: add commercially available polyamide wax (particle size D50 is 40-50 μm), glass beads, xylene and a sand mill with a circulating water bath in a certain propo...

Embodiment 2

[0043] A conductive silver paste, its composition and weight percentage are: 45% silver powder, 50% organic vehicle, 3% activated polyamide wax powder, 2% simethicone oil.

[0044] 1) Preparation of organic carrier: Weigh 90% of the total mass of organic resin and organic solvent, diethylene glycol, 3.7% of rosin, and 6.3% of polymerized rosin and add them to a double planetary power mixer mixer with a constant temperature water bath , adjust the temperature of the water bath to 80°C, the stirring speed to 600rpm, mix the materials for 2 hours, pass through a 200-mesh stainless steel sieve while it is hot, and import it into the transfer barrel;

[0045] 2) thixotropic agent activation: commercially available polyamide wax (particle size D50 is 40-50 μm), glass beads, and xylene are added to a sand mill with a circulating water bath, and the mass ratio of polyamide wax to glass beads is 1.2 : 1.0, the amount of xylene is subject to the ability to wet polyamide wax and glass be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com