Novel water-soluble immunologic adjuvant and preparing method thereof

An immune adjuvant and water-soluble technology, applied in the field of new water-soluble immune adjuvant and its preparation, can solve the problems of animal inflammatory response, large animal damage, and destruction of antigen conformation, so as to reduce the difficulty of screening, save the immunization cycle, Conservation of the effect of steric conformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A novel water-soluble immune adjuvant prepared according to the following steps:

[0023] 1. Weigh raw materials: Weigh 0.20g potassium dihydrogen phosphate, 1.30g sodium dihydrogen phosphate, 5.0g sodium chloride and 0.1g potassium chloride respectively;

[0024] 2. Dissolve the weighed potassium dihydrogen phosphate, sodium dihydrogen phosphate, sodium chloride and potassium chloride in double distilled water, set the volume to 1L and stir to dissolve, then use hydrochloric acid to adjust the pH value to 7.2 to obtain PBS phosphate buffer;

[0025] 3. Add 0.4g Poly I:C polymyocytes, 0.2g polylysine and 0.3g lentinan to the PBS phosphate buffer solution obtained in the previous step, and stir for at least 10 minutes with a magnetic stirrer to obtain the new The water-soluble immune adjuvant is then filtered and sterilized through a 0.22um filter, and finally stored in a refrigerator at 4°C.

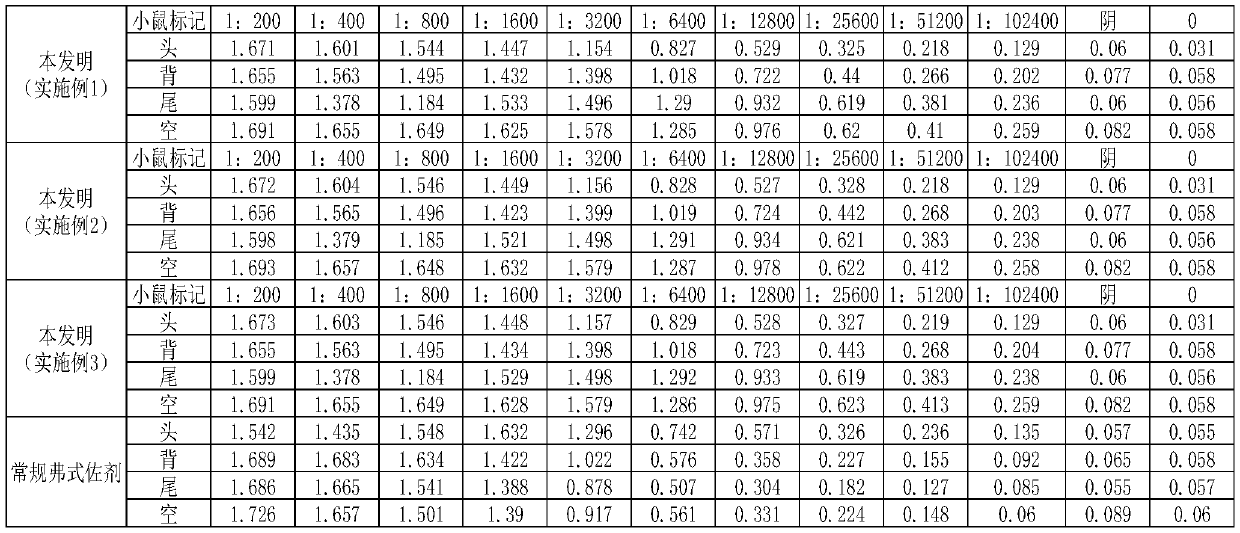

[0026] Using conventional Freund's adjuvant as a comparison, Freund's adjuv...

Embodiment 2

[0030] A novel water-soluble immune adjuvant prepared according to the following steps:

[0031] 1. Weigh raw materials: Weigh 0.27g potassium dihydrogen phosphate, 1.80g sodium dihydrogen phosphate, 15.0g sodium chloride and 0.3g potassium chloride respectively;

[0032] 2. Dissolve the weighed potassium dihydrogen phosphate, sodium dihydrogen phosphate, sodium chloride and potassium chloride in double distilled water, set the volume to 1L and stir to dissolve, then use hydrochloric acid to adjust the pH value to 7.4 to obtain PBS phosphate buffer;

[0033] 3. Add 0.6g Poly I:C polymyocytes, 0.5g polylysine and 0.7g lentinan to the PBS phosphate buffer solution obtained in the previous step, and stir for at least 10 minutes with a magnetic stirrer to obtain the new The water-soluble immune adjuvant is then filtered and sterilized through a 0.22um filter, and finally stored in a refrigerator at 4°C.

[0034] Using conventional Freund's adjuvant as a comparison, Freund's adju...

Embodiment 3

[0038] A novel water-soluble immune adjuvant prepared according to the following steps:

[0039] 1. Weigh raw materials: Weigh 0.24g potassium dihydrogen phosphate, 1.50g sodium dihydrogen phosphate, 10.0g sodium chloride and 0.2g potassium chloride respectively;

[0040]2. Dissolve the weighed potassium dihydrogen phosphate, sodium dihydrogen phosphate, sodium chloride and potassium chloride in double distilled water, set the volume to 1L and stir to dissolve, then use hydrochloric acid to adjust the pH value to 7.3 to obtain PBS phosphate buffer;

[0041] 3. Add 0.5g Poly I:C polymyocytes, 0.3g polylysine and 0.5g lentinan to the PBS phosphate buffer solution obtained in the previous step, and stir for at least 10 minutes with a magnetic stirrer to obtain the new The water-soluble immune adjuvant is then filtered and sterilized through a 0.22um filter, and finally stored in a refrigerator at 4°C.

[0042] Using conventional Freund's adjuvant as a comparison, Freund's adjuv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com