High-conductivity carbon material and preparation method thereof

A carbon material, high conductivity technology, applied in the field of high conductivity carbon material and its preparation, can solve the problems of increasing the force between the catalyst and the carrier, not having the high specific surface and high conductivity of the cathode and anode of the fuel cell, etc. Easy to control the morphology, excellent processing performance, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing a carbon material, comprising the steps of:

[0045] (1) Add 10 mg of compound 1 into a 250 ml two-necked bottle, and dissolve it in 100 ml of dichloromethane, stir well, pass nitrogen protective gas into the solution, and stir for 30 minutes;

[0046] (2) Add 1ml of pyridine to the above solution, and fully stir for 30 minutes;

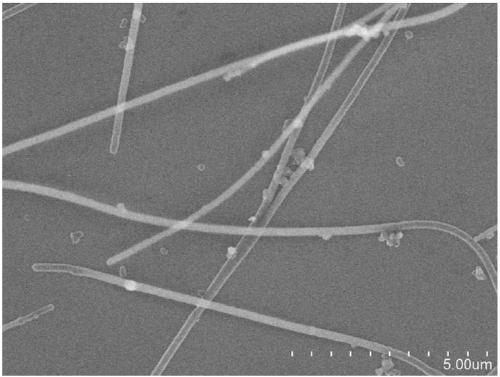

[0047] (3) Add 50 mg of copper nanowires to the above solution, control the reaction temperature at 25° C., and react for 10 hours under these conditions to obtain the following: figure 1 Carbon materials with the microstructure shown, the reaction yield is 90%.

Embodiment 2

[0049] A method for preparing a carbon material, comprising the steps of:

[0050] (1) Add 100 mg of compound 2 to a 250 ml two-necked bottle, and dissolve it in 100 ml of ether and ethyl acetate (the volume ratio of the two is 5:5), stir well, and pass argon into the solution Protective gas, stirring for 60 minutes;

[0051] (2) Add 2ml of triethylamine to the above solution, and fully stir for 30 minutes;

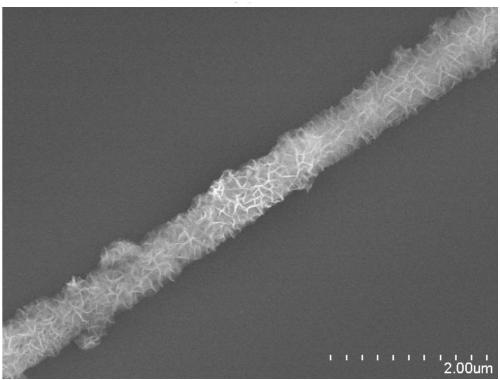

[0052] (3) Add 20 mg of copper-cobalt nanowires to the above solution, and the reaction temperature is controlled at 30° C., and reacted for 20 hours under this condition to obtain the following: figure 2 Carbon materials with the microstructure shown, the reaction yield is 95%.

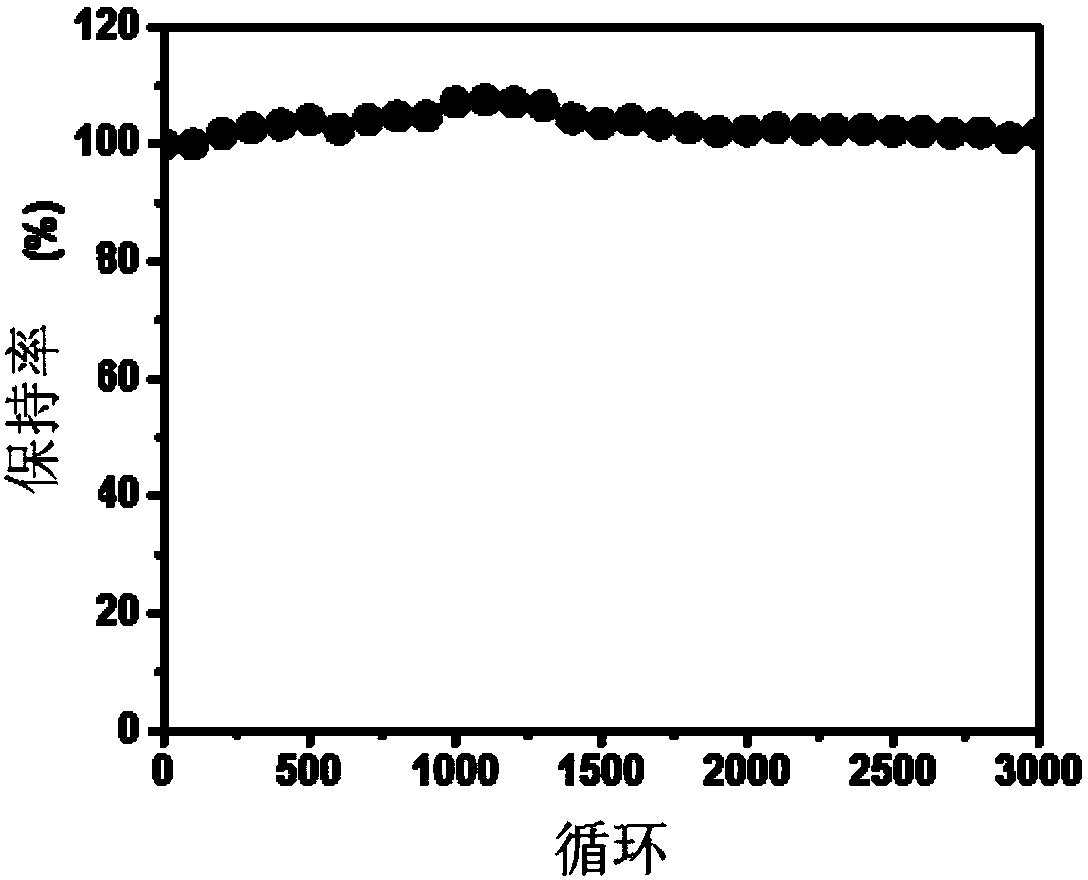

[0053] The supercapacitor assembled from the carbon nanosheets prepared above has excellent stability, and the test results are as follows: image 3 shown.

Embodiment 3

[0055] A method for preparing a carbon material, comprising the steps of:

[0056] (1) Add 200 mg of compound 4 into a 500 ml two-necked bottle, and dissolve it in 300 ml of benzene, stir well, pass argon protective gas into the solution, and stir for 60 minutes;

[0057] (2) Add 5ml of triethylenetetramine to the above solution, and fully stir for 30 minutes;

[0058] (3) Add 100 mg of copper oxide nanosheets to the above solution, and the reaction temperature is controlled at 50° C., and reacted for 15 hours under this condition to obtain the following: Figure 4 The carbon material with the microstructure shown has a reaction yield of 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com