Anti-fouling self-cleaning material and preparation method and application thereof

A self-cleaning and g-c3n4 technology is applied in the field of anti-fouling and self-cleaning materials on the surface of glass materials, which can solve problems such as insufficient anti-fouling ability, and achieve the effects of high hydrophilicity and photocatalytic ability, low price and simple production method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of the antifouling self-cleaning coating material, the specific steps are as follows:

[0024] (1) Graphite powder with a mass ratio of 1:0.8:0.8, K 2 S 2 O 8 and P 2 O 5 Add it to 24 mL of concentrated sulfuric acid with a mass concentration of 98%, react at 85°C for 4 hours, then cool to 30°C, add 1000 mL of ultrapure water, leave it for 12 hours, wash the product until it is neutral, and place it at 50°C After drying, pre-oxidized graphite was obtained; the pre-oxidized graphite was added to 240 mL of concentrated sulfuric acid with a mass concentration of 98%, and then NaNO with a mass ratio of 1:6 was added. 3 and KMnO 4 , react at 0 °C for 3 hours, heat up to 35 °C for 2 hours, add 500 mL of ultrapure water, react at 95 °C for 1 hour, then add 1000 mL of ultrapure water and 40 mL of 30% H 2 O 2 , continue the reaction for 2 hours, wash the obtained product with a HCl solution with a mass concentration of 10%, wash it with a large amou...

Embodiment 2

[0028] The preparation method of the antifouling self-cleaning coating material, the specific steps are as follows:

[0029] (1) Graphite powder with a mass ratio of 1:0.8:0.8, K 2 S 2 O 8 and P 2 O 5Add it to 24 mL of concentrated sulfuric acid with a mass concentration of 98%, react at 85°C for 4 hours, then cool to 30°C, add 1000 mL of ultrapure water, leave it for 12 hours, wash the product until it is neutral, and place it at 50°C After drying, pre-oxidized graphite was obtained; the pre-oxidized graphite was added to 240 mL of concentrated sulfuric acid with a mass concentration of 98%, and then NaNO with a mass ratio of 1:6 was added. 3 and KMnO 4 , reacted at 0 °C for 3 hours, raised the temperature to 35 °C for 2 hours, added 500 mL of ultrapure water, and reacted at 90 °C for 5 hours, then added 1000 mL of ultrapure water and 40 mL of 30% H 2 o 2 , continue the reaction for 2 hours, wash the obtained product with a HCl solution with a mass concentration of 10%...

Embodiment 3

[0033] Embodiment 1 The method for applying an antifouling self-cleaning material to a glass surface, comprising the following steps: using a glass abrasive to remove the oil stain on the glass surface to be coated, cleaning the glass surface with ethanol for 3 times, and drying it naturally for 2 hours, and applying the antifouling self-cleaning material to the glass surface. Apply the cleaning material evenly on the glass surface with a glass scraper, and let it dry naturally for 24 hours.

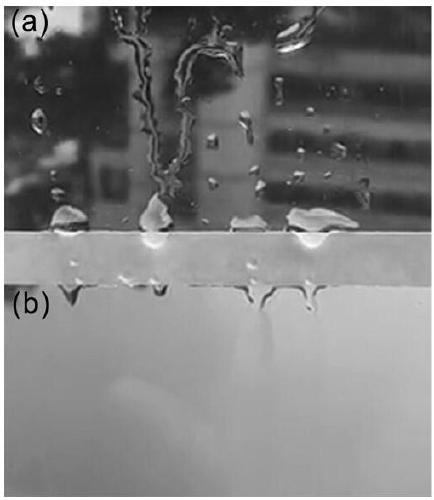

[0034] The result shows that after spraying the antifouling self-cleaning material in the present invention, the water droplet contact angle is less than 5 degrees, and the cleaning effect is as follows: figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com