Multifunctional improved material and preparation method thereof

A multi-functional, raw material technology, applied in the field of alloy modifiers, can solve the problems of slow melting of intermediate alloy modifiers, inability to modify simultaneously, and difficult control of the preparation process, so as to prevent impurity phase segregation, save slag and gas removal steps, Improvement of deterioration treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

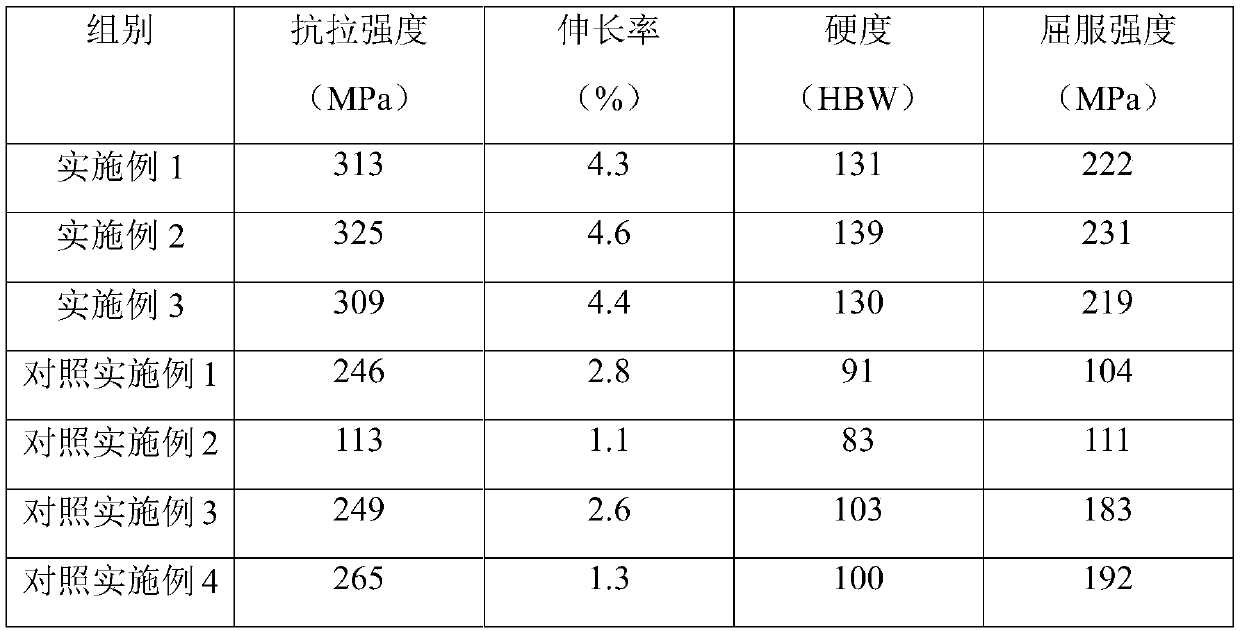

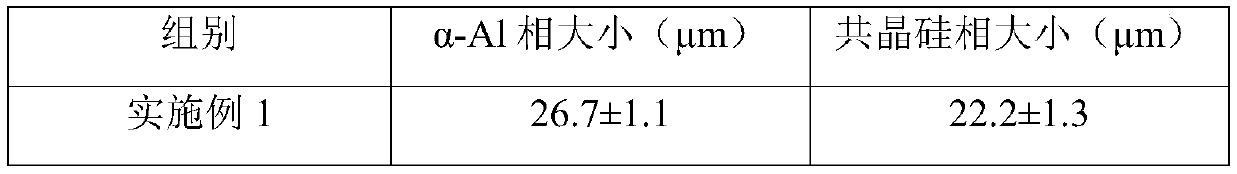

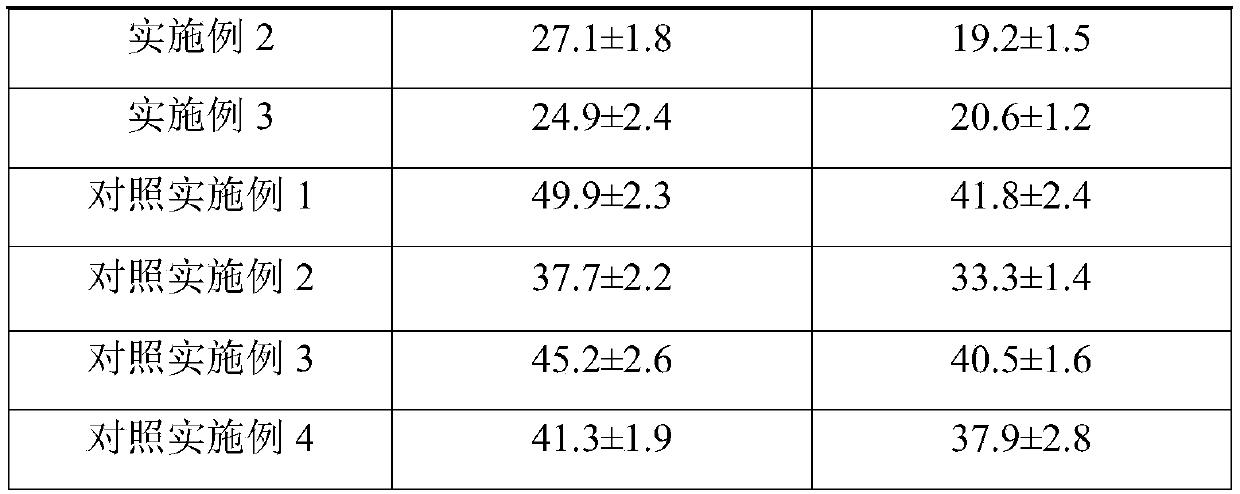

Examples

Embodiment 1

[0035] Embodiment 1: prepare multifunctional improved material as follows:

[0036] 1. Preparation of raw materials:

[0037] The purity of potassium chloride, sodium chloride, aluminum sulfate, strontium nitrate, strontium acetate, lanthanum fluoride, sodium fluorosilicate, potassium fluorozirconate, barium carbonate, chromium carbide, phosphotungstic acid, lanthanum nitrate, and Al is all greater than 99.9% wt%, the particle size is 150 mesh;

[0038] The composition of vermiculite is: Al 2 o 3 7.7wt%, H 2 O is 1.3wt%, Fe 2 o 3 is 8.4wt%, MgO is 10.2wt%, CaO+ZnO is 1.2wt%, and the balance is SiO 2 , the particle size of the vermiculite powder is 80 mesh;

[0039] The composition of A356 aluminum alloy is Si 5.0%, Fe 0.04%, Ti 0.1%, Mg 0.1%, Cu0.01%, Mn≤0.05%, Zn≤0.05%, Ca≤0.01%, and the balance is Al by weight percentage;

[0040] The inert gas is helium or argon.

[0041] 2. Preparation of multifunctional improved materials

[0042] (1) The lanthanum-containing co...

Embodiment 2

[0051] Embodiment 2: prepare multifunctional improved material as follows:

[0052] 1. Preparation of raw materials:

[0053] The purity of potassium chloride, sodium chloride, aluminum sulfate, strontium nitrate, strontium acetate, lanthanum fluoride, sodium fluorosilicate, potassium fluorozirconate, barium carbonate, chromium carbide, phosphotungstic acid, lanthanum nitrate, and Al is all greater than 99.9% wt%, the particle size is 250 mesh;

[0054] The composition of vermiculite is: Al 2 o 3 14.4wt%, H 2 O is 2.4wt%, Fe 2 o 3 is 18.9wt%, MgO is 21.5wt%, CaO+ZnO is 0.6wt%, and the balance is SiO 2 , the particle size of the vermiculite powder is 100 mesh;

[0055] The composition of A356 aluminum alloy is Si 7.0%, Fe 0.08%, Ti 0.2%, Mg 0.25%, Cu0.06%, Mn≤0.05%, Zn≤0.05%, Ca≤0.01%, and the balance is Al by weight percentage;

[0056] 2. Preparation of multifunctional improved materials

[0057] (1) The lanthanum-containing complex is prepared as follows: add 18g of p...

Embodiment 3

[0066] Embodiment 3: prepare multifunctional improved material as follows:

[0067] 1. Preparation of raw materials:

[0068] The purity of potassium chloride, sodium chloride, aluminum sulfate, strontium nitrate, strontium acetate, lanthanum fluoride, sodium fluorosilicate, potassium fluorozirconate, barium carbonate, chromium carbide, phosphotungstic acid, lanthanum nitrate, and Al is all greater than 99.9% wt%, the particle size is 200 mesh;

[0069] The composition of vermiculite is: Al 2 o 3 11.3wt%, H 2 O is 1.8wt%, Fe 2 o 3 is 13.5wt%, MgO is 16.1wt%, CaO+ZnO is less than 1.2wt%, and the balance is SiO 2 , the particle size of the vermiculite powder is 90 mesh;

[0070] The composition of A356 aluminum alloy is Si 6.0%, Fe 0.06%, Ti 0.15%, Mg 0.17%, Cu0.035%, Mn≤0.05%, Zn≤0.05%, Ca≤0.01%, and the balance is Al;

[0071] The inert gas is radon or xenon.

[0072] 2. Preparation of multifunctional improved materials

[0073] (1) The lanthanum-containing complex i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com