A kind of phosphating cold-rolled steel strip and its manufacturing method

A manufacturing method and technology of cold-rolled strip, applied in manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problem of affecting the quality of the upper film and the service life of the phosphating agent, affecting the adhesion and corrosion resistance of the paint film, and phosphating treatment. Problems such as complex process flow, to achieve the effect of improving phosphating effect and efficiency, improving formation speed and uniform density, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The chemical composition of steel for oil barrels is: C 0.030%, Mn 0.40%, Si 0.01%, Al 0.05%, P 0.018%, S 0.0035%, and the balance is Fe and impurity elements.

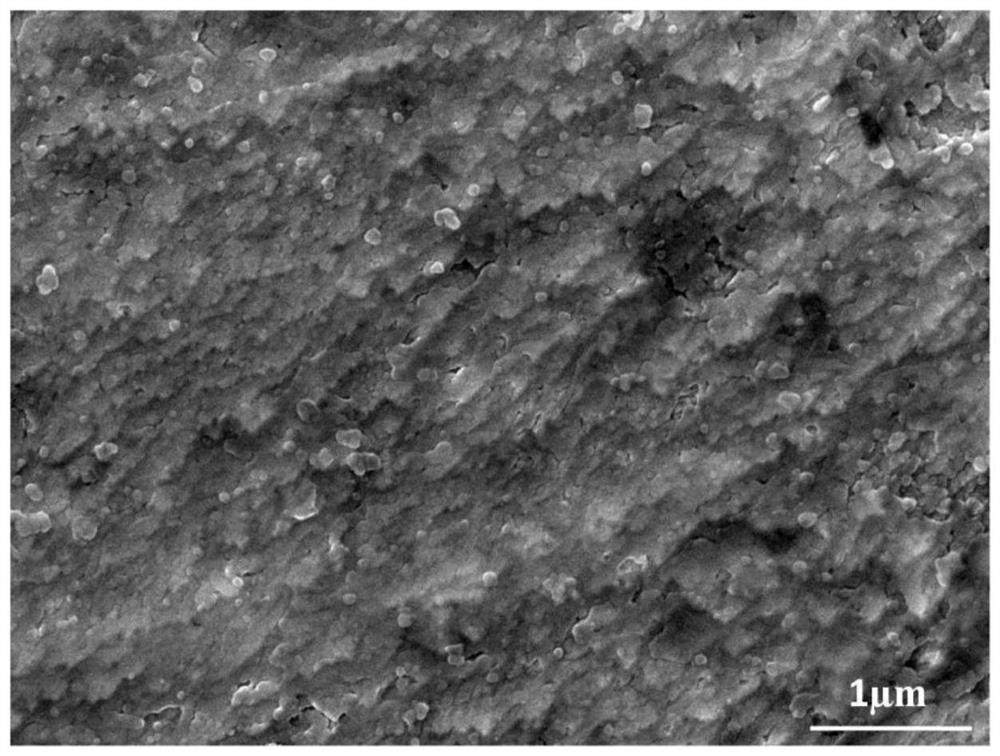

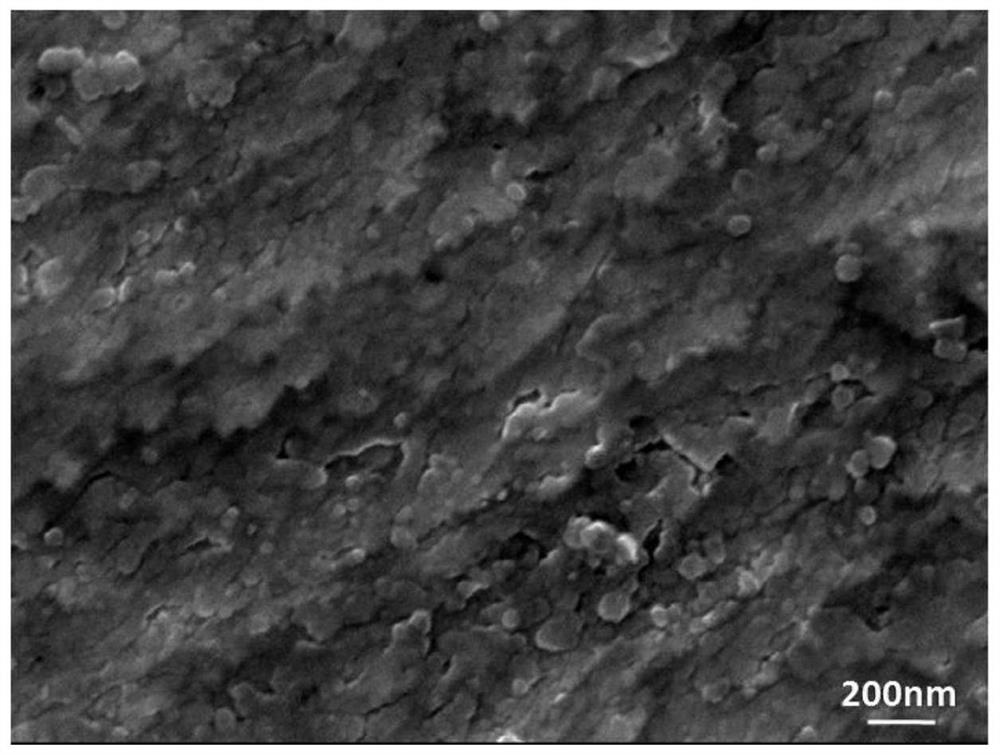

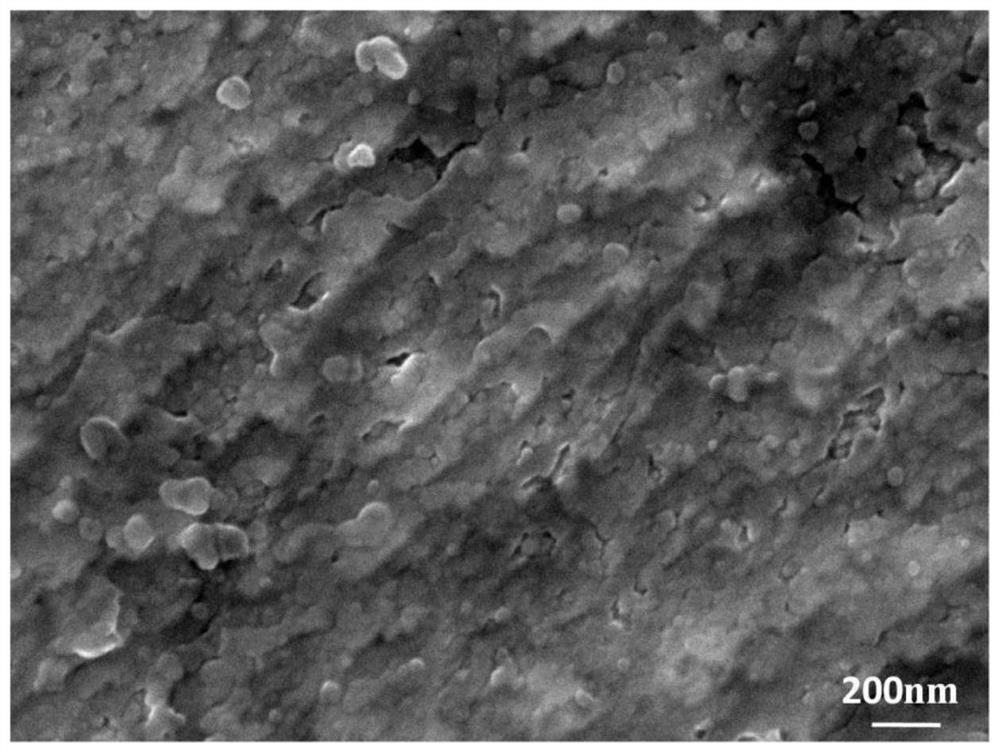

[0037] The strip steel whose chemical composition meets the above requirements is subjected to conventional treatments such as decoiling, welding, degreasing cleaning, annealing, leveling and tension leveling on the continuous annealing line. was 1.4%. After the treatment, enter the phosphating treatment area, first enter the phosphating section for phosphating treatment, the phosphating section adopts a spray process, the pH value of the phosphating solution is 2.2, the phosphating time is 41s, and the temperature of the phosphating solution is 42°C. The phosphating solution is composed of the following components: zinc dihydrogen phosphate 80g / L, zinc nitrate 69g / L, phosphoric acid 15g / L, sodium chlorate 1.9g / L, tartaric acid 5.8g / L, sodium fluoride 1.5g / L, sulfuric acid Hydroxylamine 2.2g / L, phytic acid 1.7...

Embodiment 2

[0041] The chemical composition of steel for oil barrels is: C 0.040%, Mn 0.20%, Si 0.018%, Al 0.027%, P 0.005%, S 0.011%, and the balance is Fe and impurity elements.

[0042]The strip steel whose chemical composition meets the above requirements is subjected to conventional treatments such as decoiling, welding, degreasing cleaning, annealing, leveling and tension leveling on the continuous annealing line. was 1.1%. After the treatment, enter the phosphating treatment area, first enter the phosphating section for phosphating treatment, the phosphating section adopts a spray process, the pH value of the phosphating solution is 2.8, the phosphating time is 49s, and the temperature of the phosphating solution is 45°C. The phosphating solution is composed of the following components: zinc dihydrogen phosphate 65g / L, zinc nitrate 78g / L, phosphoric acid 11g / L, sodium chlorate 1.3g / L, tartaric acid 6.8g / L, sodium fluoride 1.9g / L, sulfuric acid Hydroxylamine 1.1g / L, phytic acid 1.2...

Embodiment 3

[0046] The chemical composition of steel for oil barrels is: C 0.035%, Mn 0.30%, Si 0.04%, Al 0.01%, P 0.012%, S 0.0047%, and the balance is Fe and impurity elements.

[0047] The steel strip whose chemical composition meets the above requirements is subjected to conventional treatments such as uncoiling, welding, degreasing cleaning, annealing, leveling and tension leveling on the continuous annealing line. was 1.2%. After the treatment, enter the phosphating treatment area, first enter the phosphating section for phosphating treatment, the phosphating section adopts a spraying process, the pH value of the phosphating solution is 2.5, the phosphating time is 49s, and the temperature of the phosphating solution is 48°C. The phosphating solution is composed of the following components: zinc dihydrogen phosphate 97g / L, zinc nitrate 52g / L, phosphoric acid 18g / L, sodium chlorate 3.0g / L, tartaric acid 5.4g / L, sodium fluoride 1.2g / L, sulfuric acid Hydroxylamine 1.7g / L, phytic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com