Solvent-induced color change photonic crystal fabric and preparation and application thereof

A photonic crystal, color-changing technology, applied in textiles and papermaking, physical processing, fiber types, etc., can solve the problems of photonic crystal structure being easily damaged, lack of color-changing properties, etc., to achieve sustainable use, comfortable, stretchy Stability, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

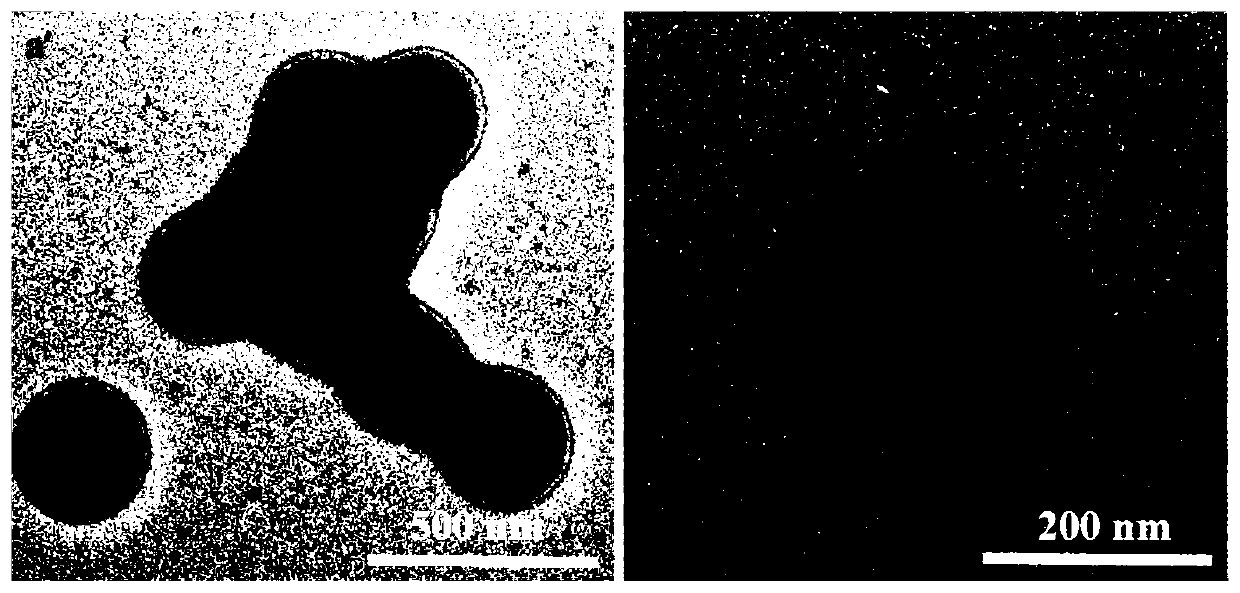

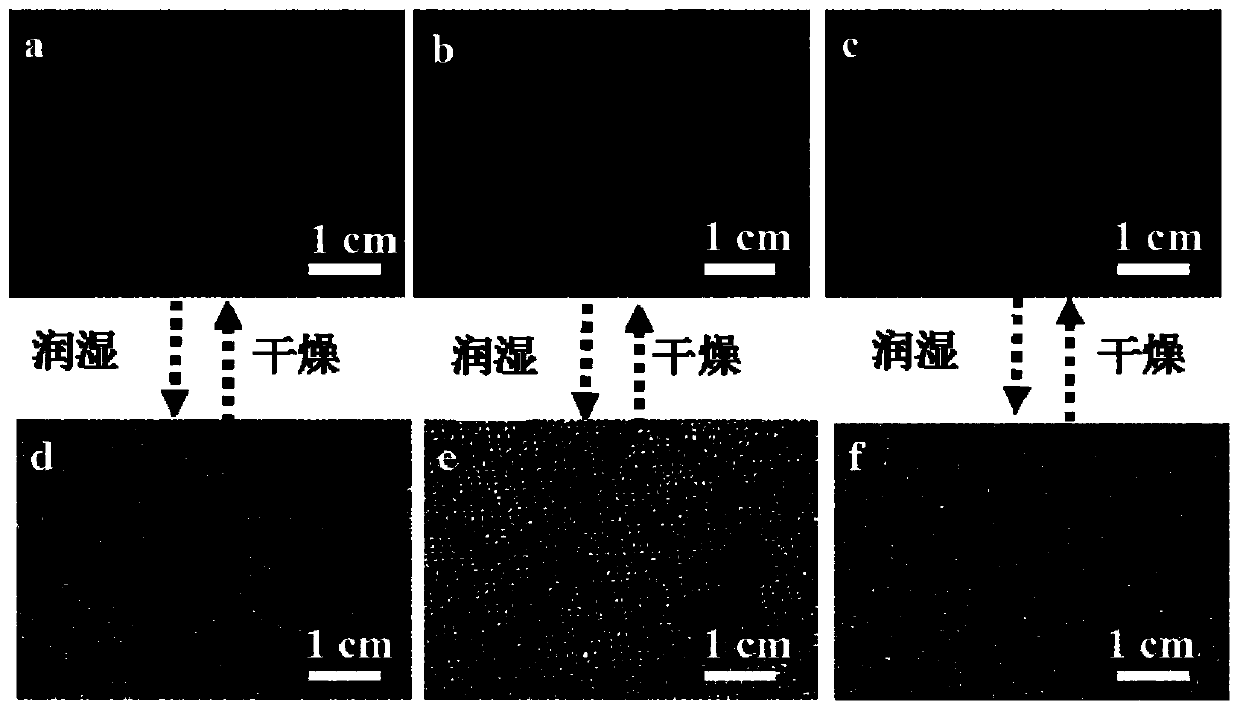

[0036]Measure 100ml of ultrapure water, 5ml of styrene, and 5ml of n-butyl acrylate into a three-necked flask, put them into an oil bath with a condensing device, set the temperature at 70°C, stir at 400rpm, and blow nitrogen for 20 minutes. Then dissolve 0.05g of potassium persulfate in 10ml of ultrapure water and add to the reaction system to initiate seed emulsion polymerization. The reaction lasts for 1h, then measure 15ml of styrene, 15ml of n-butyl acrylate, and 2ml of acrylic acid into the reaction system. After dissolving 0.2g of potassium persulfate, add it to the reaction system to initiate the next step of emulsion polymerization. The reaction lasts for 4 hours. The obtained emulsion is centrifuged and washed three times and then freeze-dried for later use. Weigh 1g of the obtained P(St-BA-AA) colloidal microspheres , ultrasonically dispersed in 3ml ultrapure water (the mass fraction of P(St-BA-AA) colloidal microspheres is 30%), then add 1.2mg of acetylene carbon bl...

Embodiment 2

[0038] Measure 100ml of ultrapure water, 5ml of styrene, and 5ml of n-butyl acrylate, weigh 0.01g of sodium dodecylbenzenesulfonate, place it in a three-necked flask, put it into an oil bath with a condensing device, and set the temperature 75°C, stirring speed 600rpm, nitrogen gas for 20min, then dissolve 0.05g potassium persulfate in 10ml ultrapure water and add to the reaction system to initiate seed emulsion polymerization, the reaction lasts 1h, then measure 15ml styrene, 15ml n-butyl acrylate, Add 2ml of acrylic acid to the reaction system, dissolve 0.2g of potassium persulfate in 20ml of ultrapure water, and then add it to the reaction system to initiate the next emulsion polymerization. The reaction lasts for 4 hours. The obtained emulsion is centrifugally washed three times and then freeze-dried for later use. Weigh 1.2 The P (St-BA-AA) colloidal microspheres that g obtains is ultrasonically dispersed in 3ml ultrapure water (the mass fraction of P(St-BA-AA) colloidal m...

Embodiment 3

[0040] Measure 100ml of ultrapure water, 5ml of styrene, and 5ml of n-butyl acrylate, weigh 0.02g of sodium dodecylbenzenesulfonate, place it in a three-necked flask, put it into an oil bath with a condensing device, and set the temperature The temperature is 80°C, the stirring speed is 800rpm, nitrogen gas is passed for 20min, and then 0.05g potassium persulfate is dissolved in 10ml ultrapure water and added to the reaction system to initiate seed emulsion polymerization. The reaction lasts for 1h, and then measure 15ml styrene, 15ml n-butyl acrylate, Add 2ml of acrylic acid to the reaction system, dissolve 0.2g of potassium persulfate with 20ml of ultrapure water, and then add it to the reaction system to initiate the next emulsion polymerization. The reaction lasts for 4 hours. The obtained emulsion is centrifugally washed three times and then freeze-dried for later use. Weigh 1.5 g obtained P (St-BA-AA) colloidal microspheres, ultrasonically dispersed in 3ml ultrapure water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com