Transient adhesive tape transfer printing method without adhesion promoter

A tape, transient technology, used in semiconductor/solid-state device manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problem of inability to accurately achieve adhesion, small adhesion switching ratio, and inability to complete transfer printing, etc. problems, to achieve the effect of improving transfer efficiency and fidelity, reducing process difficulty and cost, and enhancing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

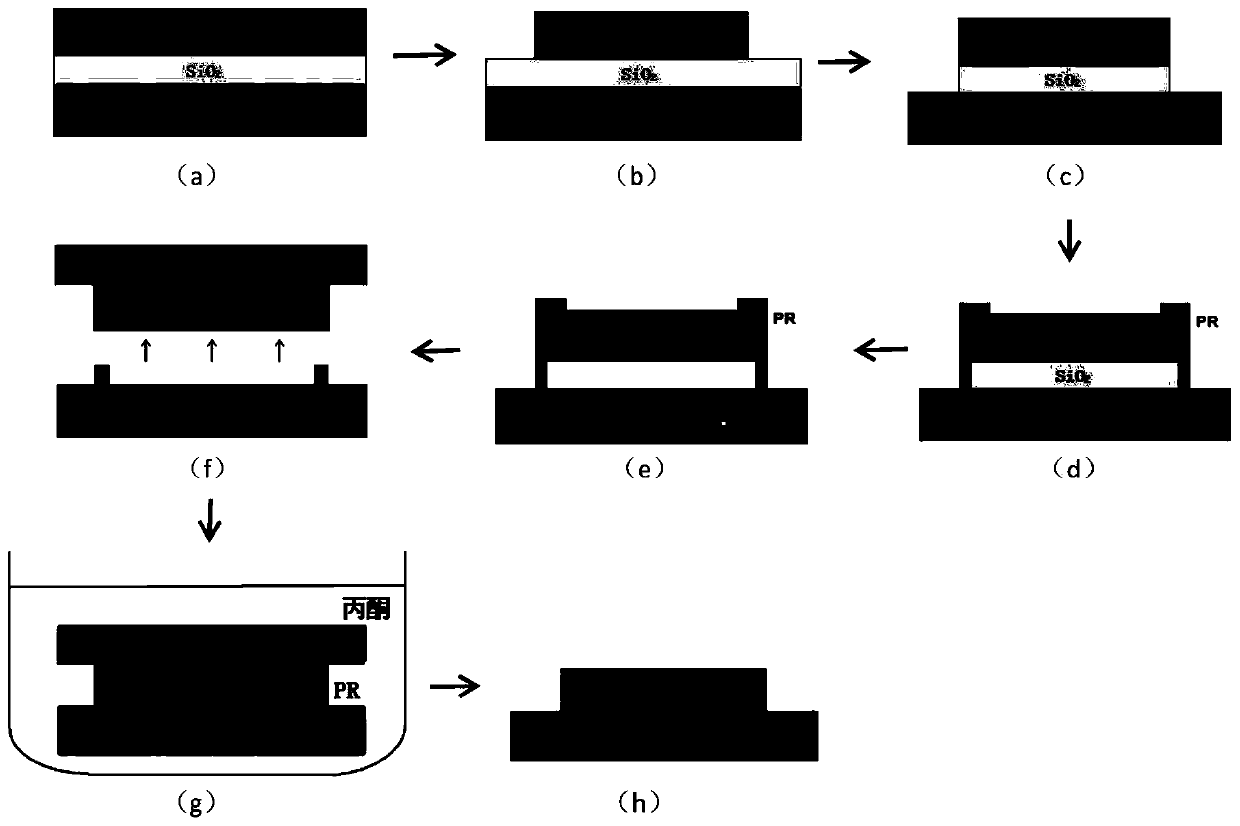

[0019] Example 1: A 200 nm thick monocrystalline silicon film was transferred by a transient adhesive tape transfer method.

[0020] Step 1, forming single crystal silicon thin film island isolation on the SOI substrate.

[0021] Select an SOI substrate with a single crystal silicon film thickness of 200nm and a buried oxide layer thickness of 200nm, such as figure 1 (a);

[0022] The photolithography process and reactive ion etching process are adopted, and the parameters of the etching machine used in the reactive ion etching process are set as follows: gas flow rate BCl 3 :Cl 2 =60: 60 sccm, the etching power is selected as 150W. On the upper part of the SOI substrate, monocrystalline silicon thin film islands are carved, such as figure 1 (b).

[0023] Step 2, partially etching the exposed buried oxide layer.

[0024] First, weigh 34.29 g of NH 4 F solid and 85.71ml of deionized water, mixed into 40% NH 4 F solution; then select 20ml of 40% HF solution, fully mix th...

Embodiment 2

[0036] Example 2: A 100 nm thick monocrystalline silicon film was transferred by a transient adhesive tape transfer method.

[0037] Step 1, forming single crystal silicon thin film island isolation on the SOI substrate.

[0038] Select an SOI substrate with a single crystal silicon film thickness of 100nm and a buried oxide layer thickness of 200nm, such as figure 1 (a);

[0039] The photolithography process and reactive ion etching process are adopted, and the parameters of the etching machine used in the reactive ion etching process are set as follows: gas flow rate BCl 3 :Cl 2 =60: 60 sccm, the etching power is selected as 150W. On the upper part of the SOI substrate, monocrystalline silicon thin film islands are carved, such as figure 1 (b).

[0040] Step 2, partially etching the exposed buried oxide layer.

[0041] First, first, weigh 34.29 g of NH 4 F solid and 85.71ml of deionized water, mixed into 40% NH 4 F solution; then select 20ml of 40% HF solution, fully...

Embodiment 3

[0052] Example 3: transfer a 150 nm thick monocrystalline silicon film by using a transient adhesive tape transfer method.

[0053] Step A, forming single crystal silicon thin film island isolation on the SOI substrate.

[0054] Select an SOI substrate with a single crystal silicon film thickness of 150nm and a buried oxide layer thickness of 200nm, such as figure 1 (a);

[0055] The photolithography process and reactive ion etching process are adopted, and the parameters of the etching machine used in the reactive ion etching process are set as follows: gas flow rate BCl 3 :Cl 2 =60: 60 sccm, the etching power is selected as 150W. On the upper part of the SOI substrate, monocrystalline silicon thin film islands are carved, such as figure 1 (b).

[0056] Step B, partially etching the exposed buried oxide layer.

[0057] First, weigh 34.29 g of NH 4 F solid and 85.71ml of deionized water, mixed into 40% NH 4 F solution; then select 20ml of 40% HF solution, fully mix the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com