Liquid crystal aligning agent, liquid crystal alignment film and liquid crystal display element

A technology of liquid crystal alignment agent and solvent, which is applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problems of reducing the display quality of display components, and achieve the effect of excellent afterimage characteristics and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0150] Examples are given below to describe the present invention more specifically, but the present invention is not limited to these Examples. The abbreviations of the following compounds and the measurement methods of each characteristic are as follows.

[0151] NMP: N-methyl-2-pyrrolidone, GBL: γ-butyrolactone,

[0152] BCS: butyl cellosolve,

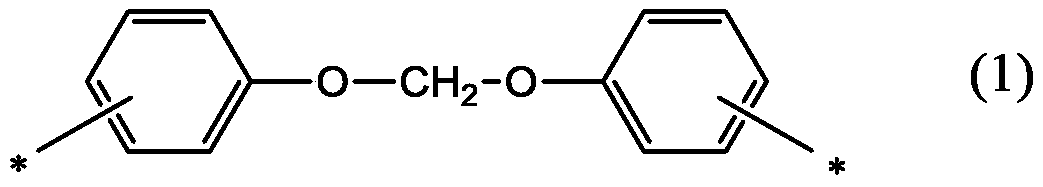

[0153] DA-1: bis(4-aminophenoxy)methane,

[0154] DA-2: 1,2-bis(4-aminophenoxy)ethane,

[0155] DA-3: N-tert-butoxycarbonyl-N-(2-(4-aminophenyl)ethyl)-N-(4-aminobenzyl)amine,

[0156] DA-4: See the following formula (DA-4),

[0157] DA-5: 2-tert-butoxycarbonylaminomethyl-p-phenylenediamine (wherein, Boc represents tert-butoxycarbonyl),

[0158] DA-6: See the following formula (DA-6),

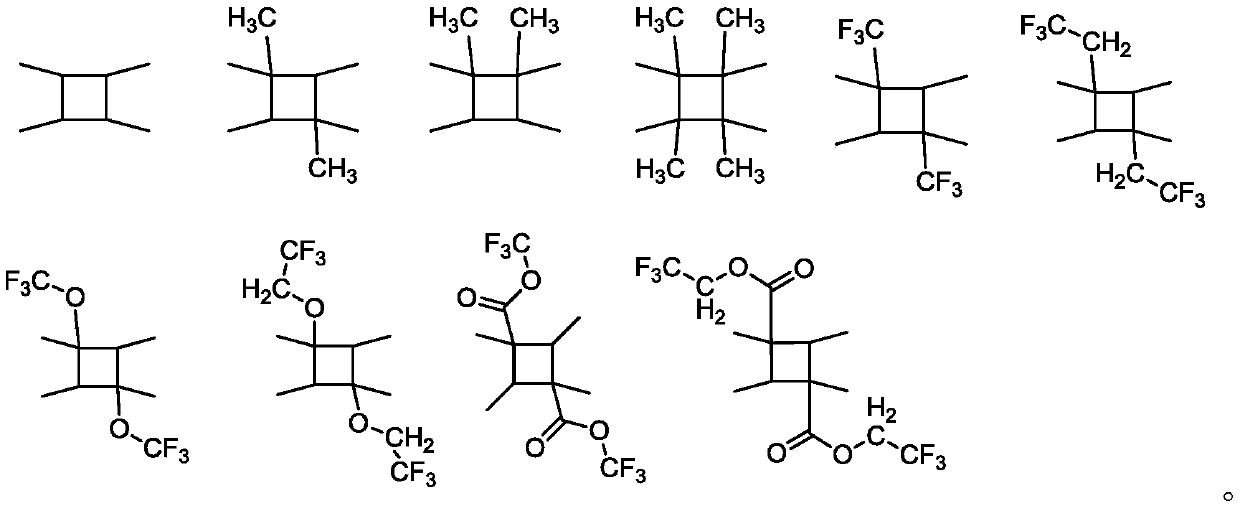

[0159] CA-1: See the following formula (CA-1), CA-2: See the following formula (CA-2),

[0160] CA-3: See the following formula (CA-3), AD-1: See the following formula (AD-1)

[0161]

[0162]

[0163] [viscosity]

[0164] The viscosity...

Synthetic example 1

[0186] Measure DA-1 1.75g (7.60mmol), DA-2 4.64g (19.0mmol) and DA-3 3.89g (11.4mmol) in a 100mL four-neck flask with a stirring device and a nitrogen inlet tube, add 46.9 g of NMP was stirred and dissolved while feeding nitrogen gas. While stirring the diamine solution, 7.93 g (35.3 mmol) of CA-1 was added, and 36.1 g of NMP was further added to make the solid content concentration 18% by mass, and stirred at 40° C. for 24 hours to obtain a polyamic acid solution (A) (Viscosity: 800mPa·s). Mn=10800 and Mw=23600 of polyamic acid.

[0187] 30 g of the obtained polyamic-acid solution was weighed in the 100-ml four-necked flask equipped with the stirring device and the nitrogen introduction pipe, NMP 37.5g was added, and it stirred for 30 minutes. 3.39 g of acetic anhydride and 0.88 g of pyridine were added to the obtained polyamic acid solution, and it heated at 55 degreeC for 3 hours, and chemically imidized it. The resulting reaction solution was poured into 270 ml of met...

Synthetic example 2

[0190] Measure DA-1 3.50g (15.2mmol), DA-2 2.78g (11.4mmol), DA-3 3.89g (11.4mmol) in a 100mL four-neck flask with a stirring device and a nitrogen inlet tube, add 46.36 g of NMP was stirred and dissolved while feeding nitrogen gas. While stirring this diamine solution, 7.92 g (35.3 mmol) of CA-1 was added, and 36.1 g of NMP was added to make the solid content concentration 18% by mass, and stirred at 40° C. for 24 hours to obtain a polyamic acid solution (C ) (viscosity: 820mPa·s). Mn=11000 and Mw=25200 of polyamic acid.

[0191] 30 g of the obtained polyamic-acid solution was weighed in the 100 mL four-necked flask equipped with the stirring device and the nitrogen introduction tube, 37.5 g of NMP was added, and it stirred for 30 minutes. 3.40 g of acetic anhydride and 0.88 g of pyridine were added to the obtained polyamic acid solution, and it heated at 55 degreeC for 3 hours, and chemically imidized it. The resulting reaction solution was poured into 270 ml of methanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com