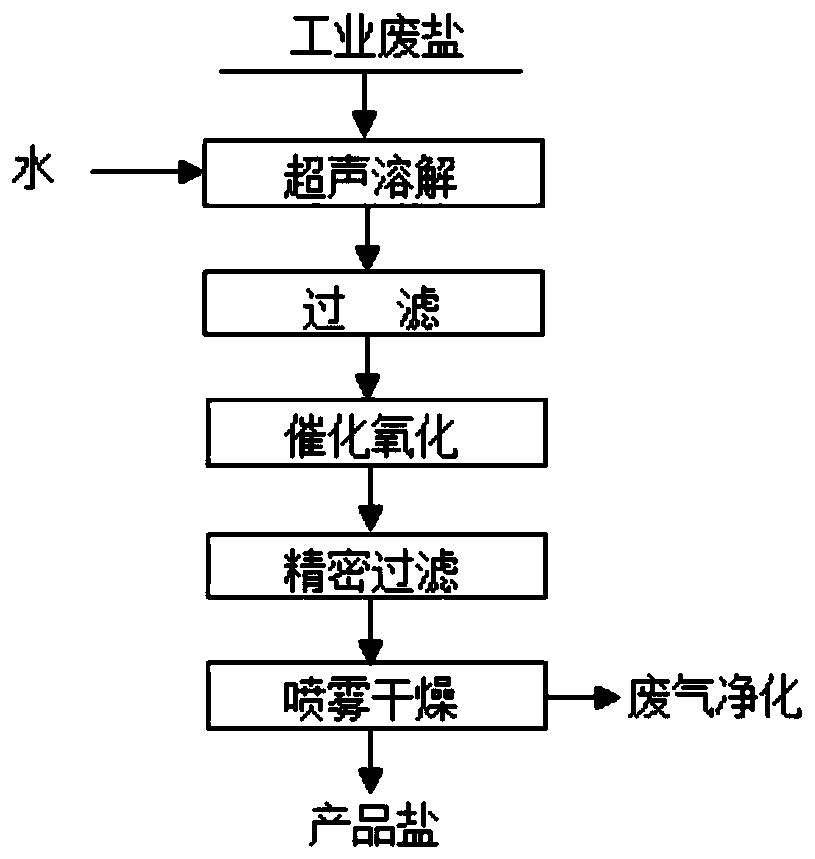

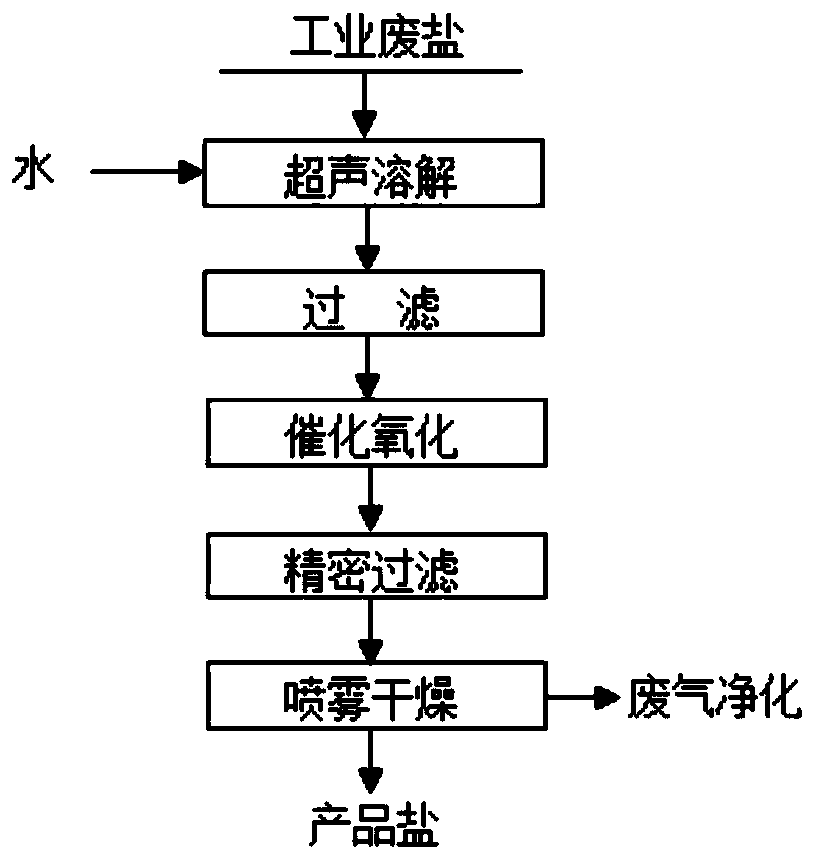

Method for harmlessness and resource utilization of waste salts in chemical industry

A resourceful and chemical technology, applied in the direction of alkali metal chloride, etc., can solve the problems of loss of adsorption, complicated technical process, high treatment cost, etc., and achieve the effect of efficient removal, simple process and high dissolution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The waste salt residue precipitated from the three-effect evaporator of a fine chemical company, the waste salt is in the form of light yellow powder lumps. After testing, the waste salt contains 86.5% sodium chloride, 4.6% water, 1.2g of organic matter and other impurities. Salt is currently entrusted to the factory as hazardous waste for treatment and disposal.

[0035] Above-mentioned waste salt is processed according to the following steps of the present invention:

[0036] Step 1: Add water into the dissolution tank, set the ultrasonic working frequency to 30kHz, turn on the ultrasonic drive power supply, and continuously add waste salt to the water until the added salt does not dissolve. At this time, the dosage of salt can be It is considered to be close to the saturated dosage of sodium chloride, and the stirring is stopped to obtain coarse concentrated brine;

[0037] Step 2, sending the coarse concentrated brine obtained in step 1 into a filter device for pre...

Embodiment 2

[0042] The waste salt of a chemical enterprise is mainly composed of sodium chloride, which is light gray in color, consolidated into lumps and slightly viscous. After sampling and analysis, the components are as follows: sodium chloride 90.1%, moisture 7.6%, organic matter 1.05% and others Impurities.

[0043] Above-mentioned waste salt is processed according to the following steps of the present invention:

[0044] Step 1: Add water into the dissolution tank, set the ultrasonic working frequency to 20kHz, turn on the ultrasonic drive power supply, and continuously add waste salt to the water until the added salt does not dissolve. At this time, the dosage of salt can be It is considered to be close to the saturated dosage of sodium chloride, and the stirring is stopped to obtain coarse concentrated brine;

[0045] Step 2, sending the coarse concentrated brine obtained in step 1 into a filter device for preliminary filtration to remove insoluble substances in the concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com