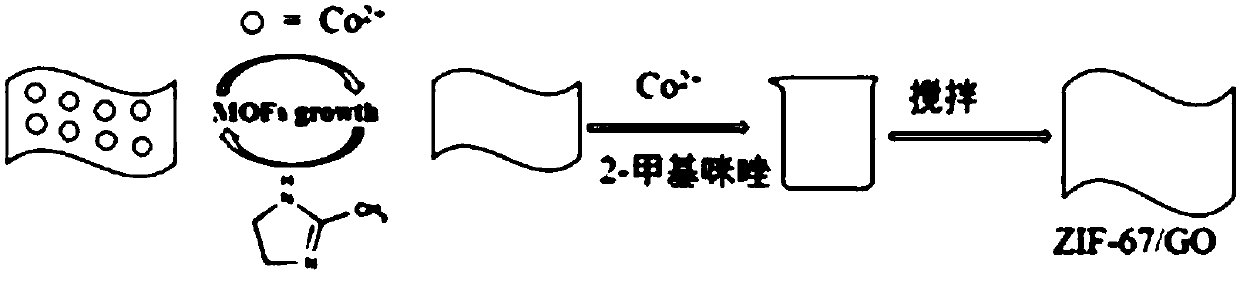

Preparation method of ZIF-67/GO composite material

A ZIF-67, 1. ZIF-67 technology, applied in nanotechnology for materials and surface science, cable/conductor manufacturing, nanotechnology, etc., can solve the problems of underutilized high specific surface of graphene oxide, etc. Achieve the effects of enhanced charge transport capability, wide applicability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: ultrasonically disperse 8 mg of graphene oxide in 20 mL of deionized water;

[0025] Step 2: 1.264g Co(NO 3 ) 2 '6H 2 O was dissolved in 48mL of methanol, 0.985g of 2-methylimidazole was dissolved in 80mL of methanol, and sonicated for 30min;

[0026] Step 3: Immerse the graphene oxide aqueous solution in 12mL Co(NO 3 ) 2 '6H 2 O and 20mL 2-methylimidazole methanol solution, stirred at room temperature for 0.5h, centrifuged at 9000rpm for 6min, alternately impregnated twice;

[0027] Step 4: Dissolve the product obtained in Step 3 in 20mL methanol for ultrasonic dispersion, and mix with 12mL Co(NO 3 ) 2 '6H 2 O methanol solution was poured into 20mL 2-methylimidazole methanol solution at the same time, and stirred vigorously for 2.5 hours, the color became rich and purplish red;

[0028] Step 5: After centrifuging the purple-red suspension obtained in Step 4, dry it at 80° C. for 6 hours under vacuum.

[0029] Step 6: The purple-red ZIF-67 / GO powder ob...

Embodiment 2

[0032]Step 1: ultrasonically disperse 10 mg of graphene oxide in 20 mL of deionized water;

[0033] Step 2: 1.264g Co(NO 3 ) 2 '6H 2 O was dissolved in 48mL of methanol, 2.624g of 2-methylimidazole was dissolved in 80mL of methanol, and sonicated for 30min;

[0034] Step 3: Immerse the graphene oxide aqueous solution in 12mL Co(NO 3 ) 2 '6H 2 O methanol solution and 20mL 2-methylimidazole methanol solution, stirred at room temperature for 0.5h, centrifuged at 9000rpm for 6min, alternately impregnated twice in a cycle;

[0035] Step 4: Dissolve the product obtained in Step 3 in 20mL methanol for ultrasonic dispersion, and mix with 12mL Co(NO 3 ) 2 '6H 2 O methanol solution was poured into 20mL 2-methylimidazole methanol solution simultaneously, stirred vigorously for 3.5 hours;

[0036] Step 5: After centrifuging the purple suspension obtained in Step 4, dry it at 80° C. for 6 hours under vacuum.

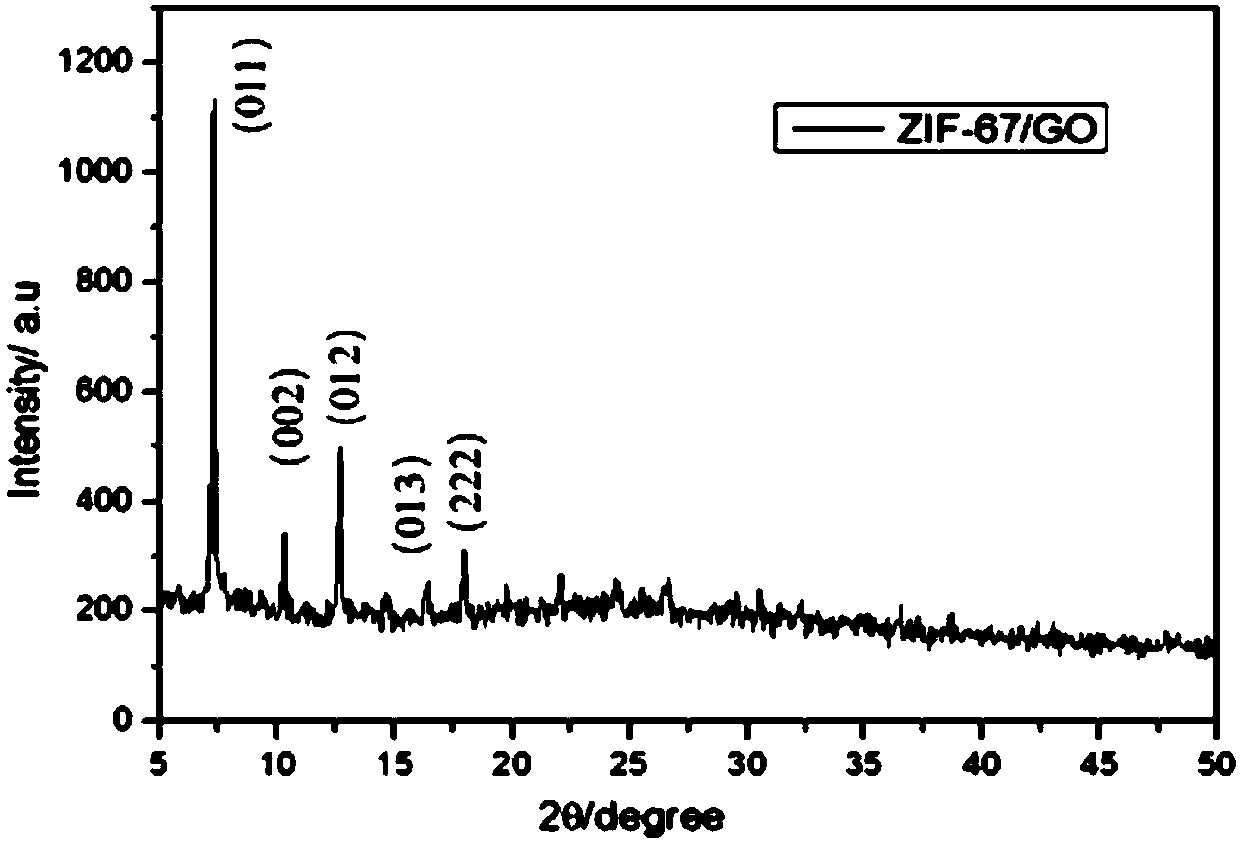

[0037] The ZIF-67 / GO material prepared under this condition has ZIF-67...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com