Gas medium based temperature-controlled and voltage-controlled lithium battery formation device

A gas medium and formation device technology, which is applied in the field of lithium battery formation equipment, can solve problems such as uneven force, uneven wrinkles, and inconsistent distance between pole pieces, so as to avoid pollution and deformation, no short circuit danger, and convenience good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

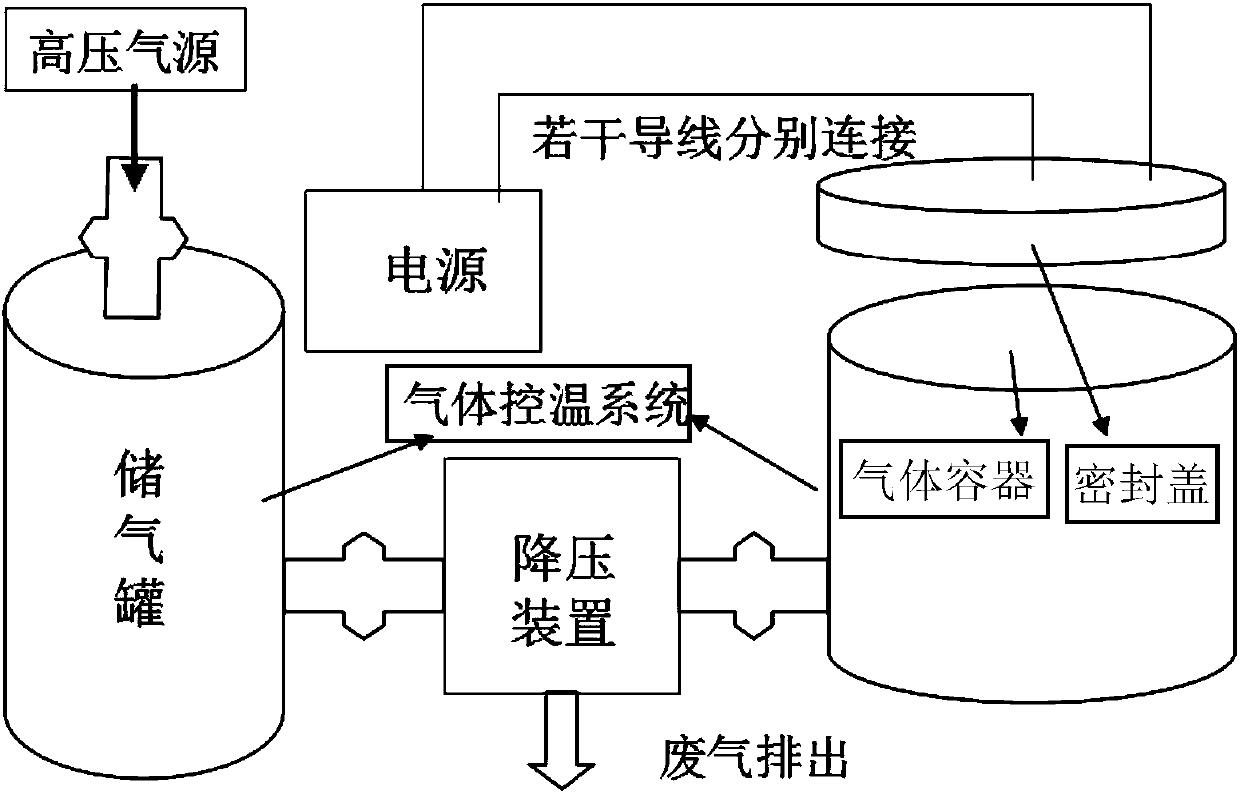

[0047] Such as figure 1 As shown, the chemical conversion device includes a power supply and its connected sealing cover, a gas storage tank and its pressure reducing device, a gas temperature control system, a gas container and its pressure reducing device, and the like.

[0048] The sealing cover, the gas storage tank, the pressure reducing device and the sealing tank body are all made of pressure-resistant stainless steel, and the gas container is equipped with a material rack made of polytetrafluoroethylene for placing lithium batteries.

[0049] The power supply is connected with the sealing cover, and four poles are arranged on the sealing cover, and the poles are insulated. The connection between the pole and the cover is sealed and blocked in a structural way.

[0050] The power supply has the functions of measuring the voltage, current, temperature, capacitance and internal resistance of the lithium battery between the poles.

[0051] After the high-pressure gas is in...

Embodiment 2

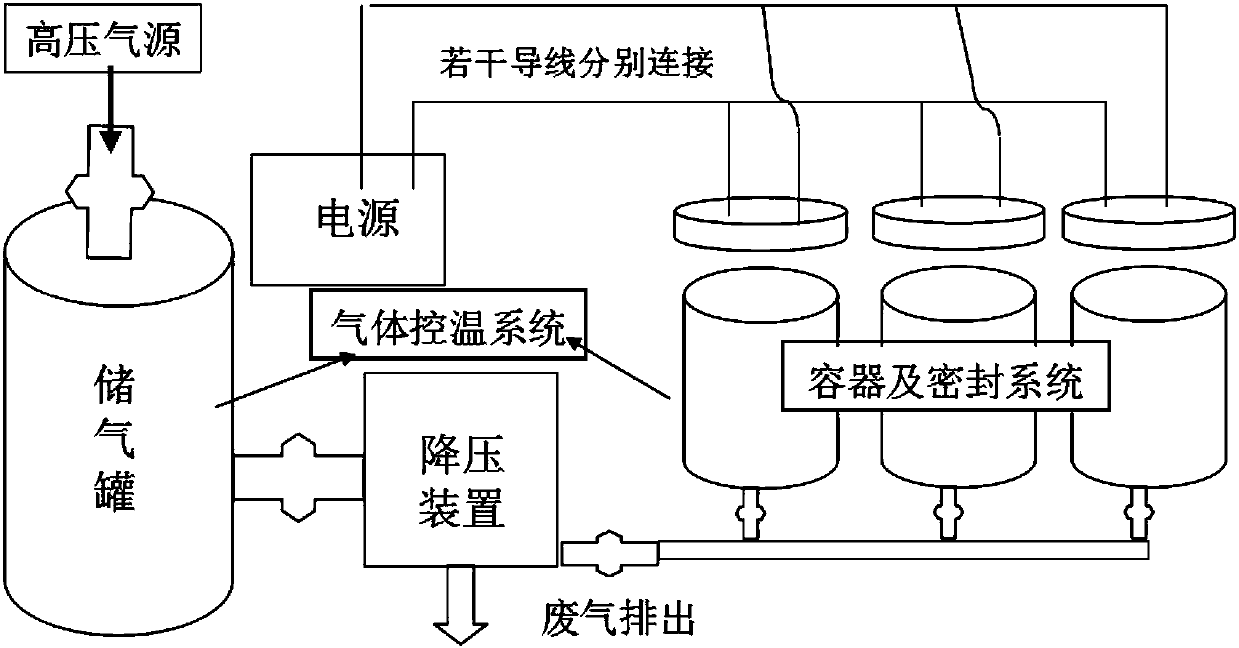

[0055] The difference from Embodiment 1 is that there are multiple gas containers and corresponding sealing systems, and the same mechanism can be used for pressurization of the sealing systems. The sealing system can be sealed with the gas container by pressurization. The product of pressure and volume of any gas container in the whole system is less than 2.5MPa*L. The sealing adopts a screw sealing cover and is driven by a pneumatic rod. This embodiment can be used for temperature-controlled and pressure-controlled chemical formation equipment that uses dry air as a medium and has a relatively high safety factor and is not a special equipment.

Embodiment 3

[0057] On the basis of Example 1, while increasing the concentration of organic molecules in the equipment to detect the waste gas, a kind of chemical formation equipment with inert gas as the medium, temperature control and pressure control, and lithium battery leak detection can be formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com