Lignin-based nanoflower porous carbon carrier-supported Ru-based catalyst as well as preparation method thereof and application of catalyst in lignin depolymerization

A lignin-based, carrier-loaded technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of easy repolymerization of products and easy loss of active components and other problems, to achieve the effects of desorption, excellent activity, and increase in specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Weigh 1 mass part of alkali lignin, weigh 0.5 mass part of magnesium oxide and add it to 20 volume parts of water, and continue stirring for 1 h at a speed of 300-500 rpm to form a uniform gray-yellow mixture.

[0055] (2) The mixture was transferred to a microwave reactor, raised to 200° C. for 5 minutes at a rate of 10° C. / min, and reacted for 5 minutes to obtain a light yellow mixture.

[0056] (3) Put the light yellow mixture into a freeze dryer at -50°C and dry for 24 hours to obtain a composite of lignin and magnesium oxide.

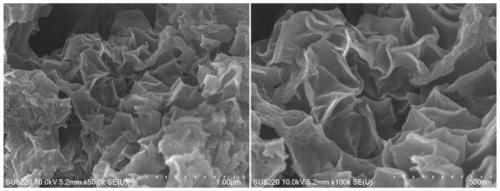

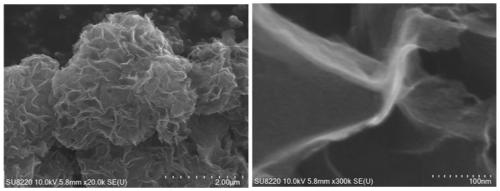

[0057] (4) transfer the compound obtained into the tube furnace, under N 2 Under the atmosphere of 3°C / min, the temperature was raised to 400°C at a constant temperature of 1h to obtain a black solid. After the calcined product was ground, it was mixed with 200 volume parts (2mol / L) of HCl, stirred at a speed of 400rpm for 12h, and statically After standing for 24 hours, filter, wash with water until neutral, and dry at 50° C. for 24 ho...

Embodiment 2

[0062] (1) Weigh 1 mass part of enzymatic lignin, weigh 5 mass parts of magnesium oxide and add it to 30 volume parts of water, and continue to stir for 1 h at a speed of 300-500 rpm to form a uniform gray-yellow mixture.

[0063] (2) The mixture was transferred to a microwave reactor, and raised to 100°C for 10 minutes at a heating rate of 60°C / min to obtain a light yellow mixture.

[0064] (3) Put the light yellow mixture into a freeze dryer at -50°C and dry for 24 hours to obtain a composite of lignin and magnesium oxide.

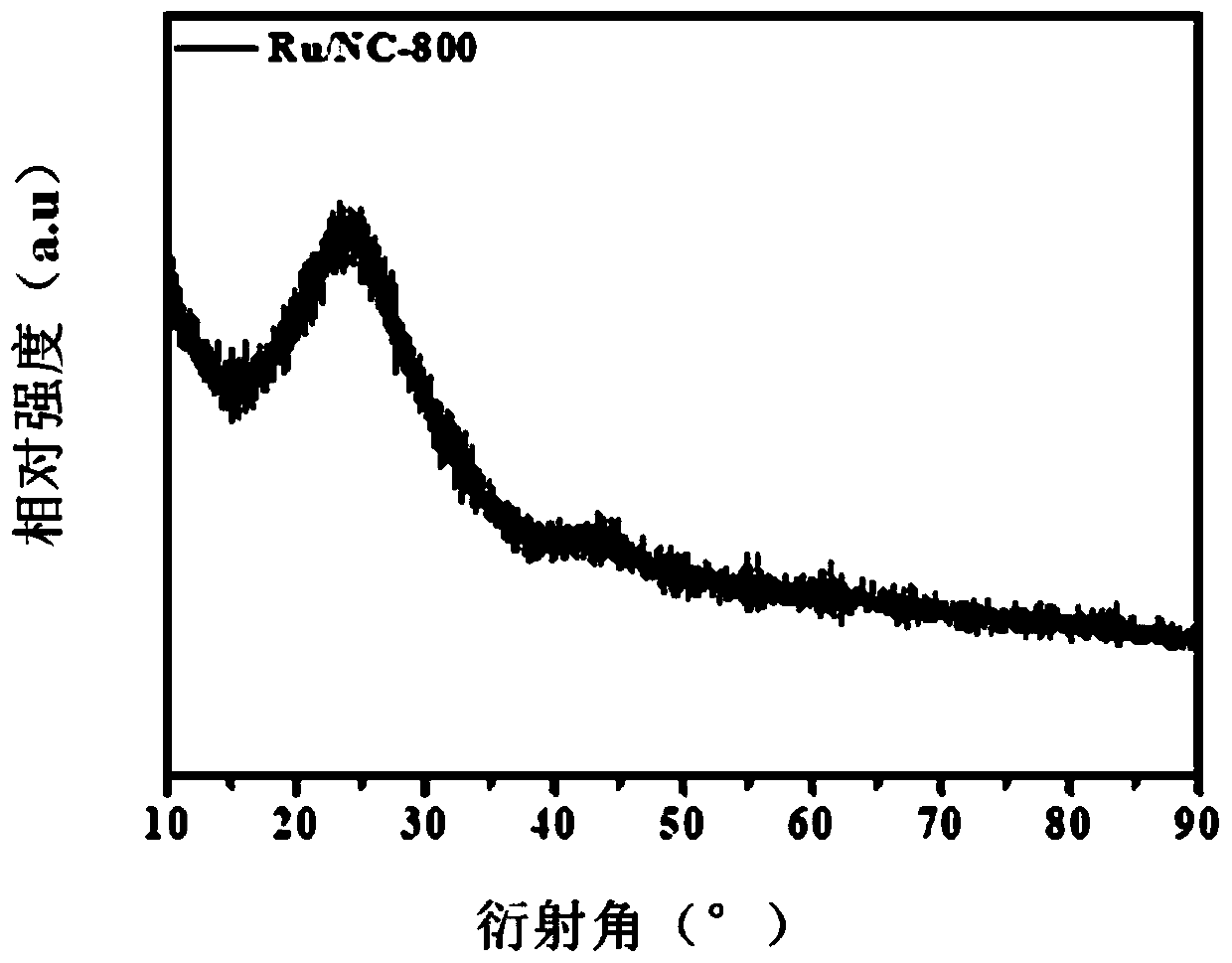

[0065] (4) transfer the compound obtained into the tube furnace, under N 2 Under an atmosphere of 15°C / min, the temperature was raised to 800°C at a constant temperature of 6h to obtain a black solid. After the calcined product was ground, it was mixed with 200 parts by volume (2mol / L) of HCl, stirred at a speed of 400rpm for 12h, and statically After standing for 24 hours, filter, wash with water until neutral, and dry at 50° C. for 24 hours to obtain ...

Embodiment 3

[0070] (1) Weigh 1 part by mass of the organic solvent lignin, add 1 part by mass of magnesium oxide into 30 parts by volume of water, and continue stirring for 1 hour at a speed of 300-500 rpm to form a uniform gray-yellow mixture.

[0071] (2) The mixture was transferred to a microwave reactor and raised to 50°C for 30 minutes at a heating rate of 20°C / min to obtain a light yellow mixture.

[0072] (3) Put the light yellow mixture into a freeze dryer at -50°C and dry for 24 hours to obtain a composite of lignin and magnesium oxide.

[0073] (4) transfer the compound obtained into the tube furnace, under N 2Under an atmosphere of 10°C / min, the temperature was raised to 600°C at a constant temperature of 1h to obtain a black solid, and the calcined product was ground and mixed with 200 volume parts (2mol / L) of HCl, stirred at a speed of 400rpm for 12h, and statically After standing for 24 hours, filter, wash with water until neutral, and dry at 50° C. for 24 hours to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Edge thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com