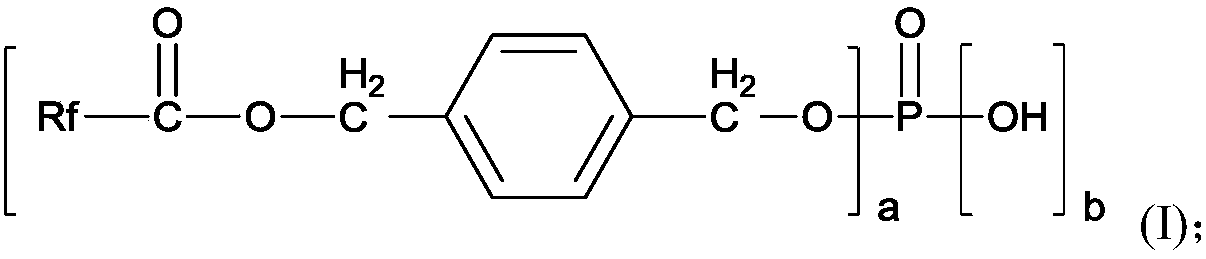

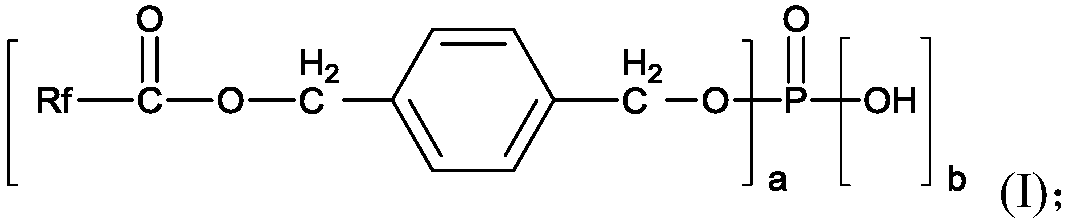

Perfluoropolyether phosphate compound, preparation method and application thereof

A technology for perfluoropolyether phosphate esters and compounds, which is applied in the fields of phosphorus organic compounds, chemical instruments and methods, compounds of elements of Group 5/15 of the periodic table, etc., can solve the problems of polluting the environment, cumbersome steps and complicated operations, To achieve the effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

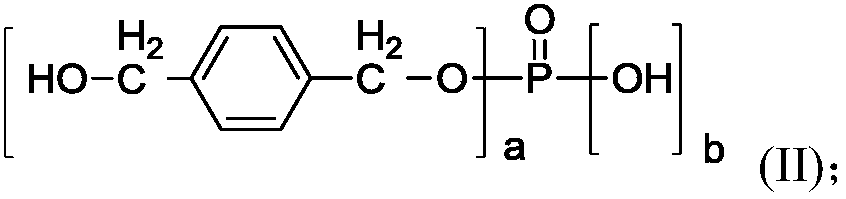

[0045] In an anhydrous, oxygen-free nitrogen atmosphere, mix 10g of phosphorus oxychloride, 18.02g of 1,4-tere-phenylenedimethanol, and 100mL of tetrahydrofuran, stir and raise the temperature to 35°C, maintain this temperature for 9 hours, add 1mL of deionized water to continue the stirring reaction 1 h, during which the temperature remained constant. After the reaction was over, distillation under reduced pressure gave 13.18 g of intermediates with a yield of 83.05%.

[0046] Under anhydrous and oxygen-free nitrogen atmosphere, 10g of the intermediate (41.10mmol), 66g of perfluoropolyetheryl fluoride (n=6, Mn=1328g / mol), 100mL of trifluorotrichloroethane and 3mL of triethylamine were mixed, Stir and heat up to 25°C, maintain this temperature for 8 hours, and purify the crude product by distillation under reduced pressure to obtain a perfluoropolyether phosphoric acid ester compound (wherein the molar ratio of the perfluoropolyether phosphoric acid monoester compound to the p...

Embodiment 2

[0048]In an anhydrous, oxygen-free nitrogen atmosphere, mix 5g of phosphorus oxychloride, 9.01g of 1,4-tere-phenylenedimethanol, and 50mL of dichloromethane, stir and raise the temperature to 25°C, maintain this temperature for 9h, add 1mL of deionized water to continue The reaction was stirred for 1 h, during which the temperature was kept constant. After the end of the reaction, distillation under reduced pressure yielded 6.21g of intermediates with a yield of 80.65%.

[0049] Under anhydrous and oxygen-free nitrogen atmosphere, mix 5g of the intermediate (21.2mmol), 40g of perfluoropolyether fluoride (n=8, Mn=1660g / mol), 100mL of tetrahydrofuran, and 3mL of triethylamine, stir and heat up to 25°C , maintain this temperature for 8 hours, and purify the crude product by distillation under reduced pressure to obtain a perfluoropolyether phosphoric acid ester compound (wherein the molar ratio of the perfluoropolyether phosphoric acid monoester compound to the perfluoropolyether...

Embodiment 3

[0051] In an anhydrous, oxygen-free nitrogen atmosphere, mix 10g of phosphorus oxychloride, 18.02g of 1,4-tere-phenylenedimethanol, and 100mL of carbon tetrachloride, stir and raise the temperature to 25°C, maintain this temperature for 9 hours, and add 1mL of deionized water Continue to stir the reaction for 1 h, during which the temperature remains constant. After the end of the reaction, distillation under reduced pressure yielded 12.80g of intermediates with a yield of 83.95%.

[0052] Under anhydrous and oxygen-free nitrogen atmosphere, mix 10g of the intermediate (42.78mmol), 110g of perfluoropolyetheryl fluoride (n=12, Mn=2324g / mol), 100mL of tetraethylene glycol dimethyl ether, and 3mL of triethylamine , stirred and heated up to 25°C, maintained at this temperature for 8 hours, and the crude product was purified by distillation under reduced pressure to obtain a perfluoropolyether phosphoric acid ester compound (wherein, the moles of the perfluoropolyether phosphoric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com