High weatherability anticorrosion paint

A technology of anti-corrosion coatings and high weather resistance, applied in anti-corrosion coatings, coatings, etc., can solve the problems of short anti-corrosion period and achieve the effects of enhanced adhesion, excellent weather resistance and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

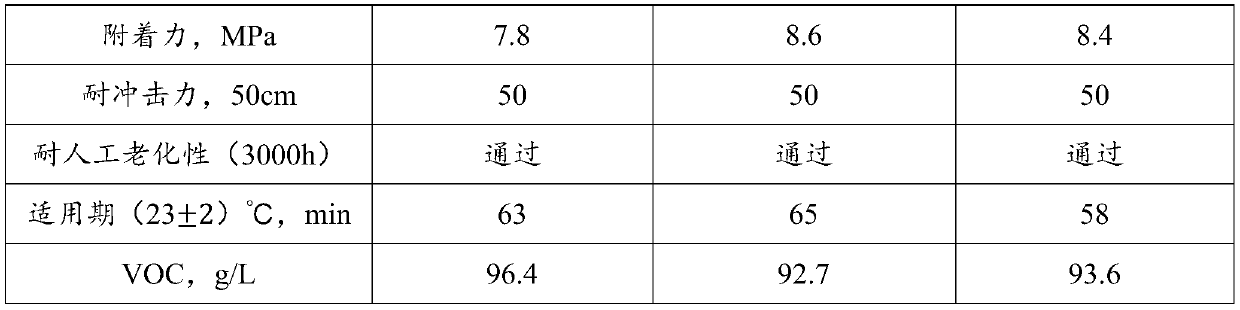

Embodiment 1

[0027] The preferred embodiment of the present invention provides a highly weather-resistant and anticorrosive paint, in which 10 parts by weight of amino resin, 11 parts of silicone resin, and 30 parts of polyol are placed in a container at a speed of 1000-1200r / min. Disperse and mix for 10-15min; add 31 parts by weight of organic solvent, and disperse and mix for 15-20min at a speed of 1500-1700r / min; add 0.01 part by weight of antioxidant and 0.06 part of catalyst Disperse and mix for 30-40min at a speed of 2000-2400r / min.

Embodiment 2

[0029] In this example, on the basis of Example 1, 13 parts by weight of amino resin, 12 parts of silicone resin, and 33 parts of polyol were placed in a container, and dispersed and mixed 10 parts at a rotation speed of 1000-1200r / min. -15min; add 35 parts by weight of organic solvent, disperse and mix for 15-20min at a speed of 1500-1700r / min; add 0.02 parts by weight of antioxidant and 0.07 parts of catalyst at 2000-2400r Disperse and mix at a speed of 30-40min at a speed of 30-40min

Embodiment 3

[0031] In this example, on the basis of Example 1, 15 parts by weight of amino resin, 13 parts of silicone resin, and 35 parts of polyol are placed in a container, and dispersed and mixed 10 parts at a rotation speed of 1000-1200r / min. -15min; add 39 parts by weight of organic solvent, disperse and mix for 15-20min at a speed of 1500-1700r / min; add 0.03 part by weight of antioxidant and 0.08 part of catalyst at 2000-2400r Disperse and mix at a speed of 30-40 min at a speed of 30-40 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com