Acrylate adhesive for assembling wind power electromagnetic assembly, preparation method thereof and using method thereof

An acrylate and acrylate-based technology, applied in the direction of adhesive additives, ester copolymer adhesives, adhesive types, etc., can solve the problem of affecting the bonding strength of adhesives, coating peeling off, chemical balance is easily destroyed, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

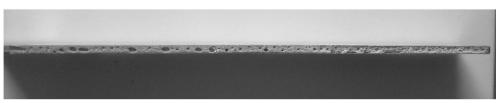

Image

Examples

specific Embodiment approach 1

[0039] An acrylic adhesive for assembling wind power generation electromagnetic components, the acrylic adhesive for assembling wind power generation electromagnetic components is mainly made of the first component and the second component; the first group Parts include the following composition and parts by weight: 65-70 parts of the first methacrylate or acrylate monomer, 15-20 parts of the first elastomer toughening agent, 2.5-5 parts of adhesion and tackifier, which promote 8-12 parts of the first stabilizer, 0.3-0.5 parts of the first stabilizer; the second component includes the following composition and parts by weight: 70-75 parts of the second methacrylate or acrylate monomer, 70-75 parts of the second 15-20 parts of elastomer toughening agent, 3-5 parts of coupling agent, 2-3 parts of initiator, 0.3-0.5 parts of second stabilizer.

[0040] The acrylic adhesive for assembling wind power generation electromagnetic components described in this embodiment, the first meth...

specific Embodiment approach 2

[0054] An acrylic adhesive for assembling wind power generation electromagnetic components, the acrylic adhesive for assembling wind power generation electromagnetic components is mainly made of the first component and the second component; the first group Parts include the following composition and parts by weight: 65-70 parts of the first methacrylate or acrylate monomer, 15-20 parts of the first elastomer toughening agent, 2.5-5 parts of adhesion and tackifier, which promote 8-12 parts of the first stabilizer, 0.3-0.5 parts of the first stabilizer; the second component includes the following composition and parts by weight: 70-75 parts of the second methacrylate or acrylate monomer, 70-75 parts of the second 15-20 parts of elastomer toughening agent, 3-5 parts of coupling agent, 2-3 parts of initiator, 0.3-0.5 parts of second stabilizer.

[0055] The acrylic adhesive for assembling wind power generation electromagnetic components described in this embodiment, the first meth...

specific Embodiment approach 3

[0071] A method for preparing an acrylic adhesive for assembling a wind power generation electromagnetic component according to the specific embodiment 1 or 2, comprising the following steps:

[0072] Step 1. Weigh 65-70 parts of the first methacrylate or acrylate monomer, 15-20 parts of the first elastomer toughening agent, 2.5-5 parts of the adhesion promoter, and 8-5 parts of the accelerator 12 parts, 0.3 to 0.5 parts of the first stabilizer, first mix the first methacrylate or acrylate monomer and the first elastomer toughening agent evenly, then continue to add adhesion tackifier, accelerator, The first stabilizer, after stirring and mixing uniformly, obtains the first component, which is ready for use;

[0073] Step 2. Weigh 70-75 parts of the second methacrylate or acrylate monomer, 15-20 parts of the second elastomer toughening agent, 3-5 parts of the coupling agent, and 2-3 parts of the initiator , the second stabilizer 0.3 ~ 0.5, firstly mix the second methacrylate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com