Manufacturing method of full-color Micro-LED display device based on quantum dot photo-conversion layer

A light conversion layer and display device technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve problems such as optical crosstalk, light source arrays and quantum dot film layers are tightly adhered and difficult to separate, so as to improve utilization rate, Filter out harmful spectral components to the human eye and avoid cross-linking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

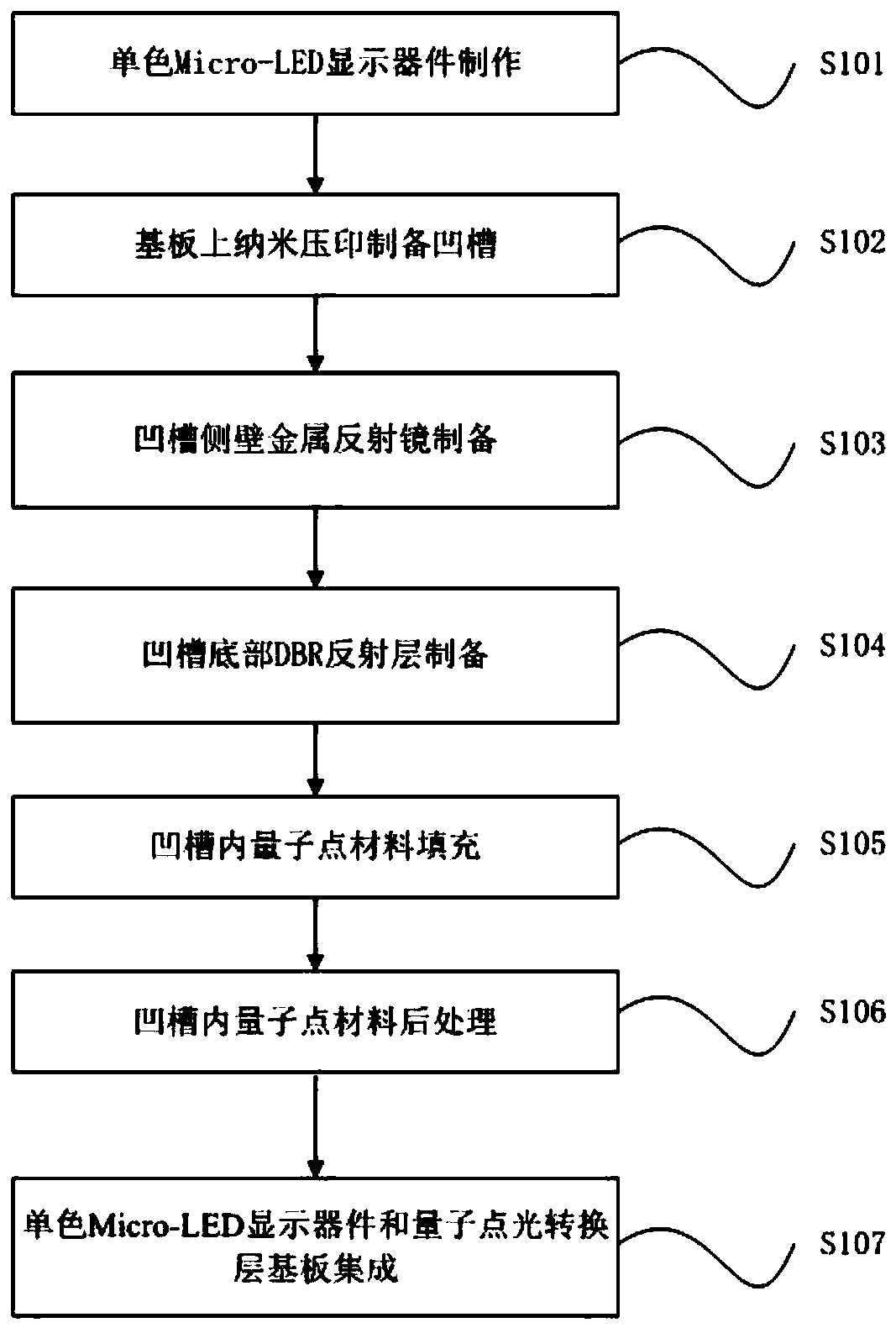

[0025] Specific implementation mode 1. Combination Figure 1 to Figure 4 Describe this embodiment, the fabrication method of the full-color Micro-LED display device based on the quantum dot light conversion layer, the method is realized by the following steps:

[0026] Step S101: Provide a blue LED epitaxial wafer with a sapphire substrate 17, a Si-based CMOS passive drive backplane, and manufacture a monochrome Micro-LED display device;

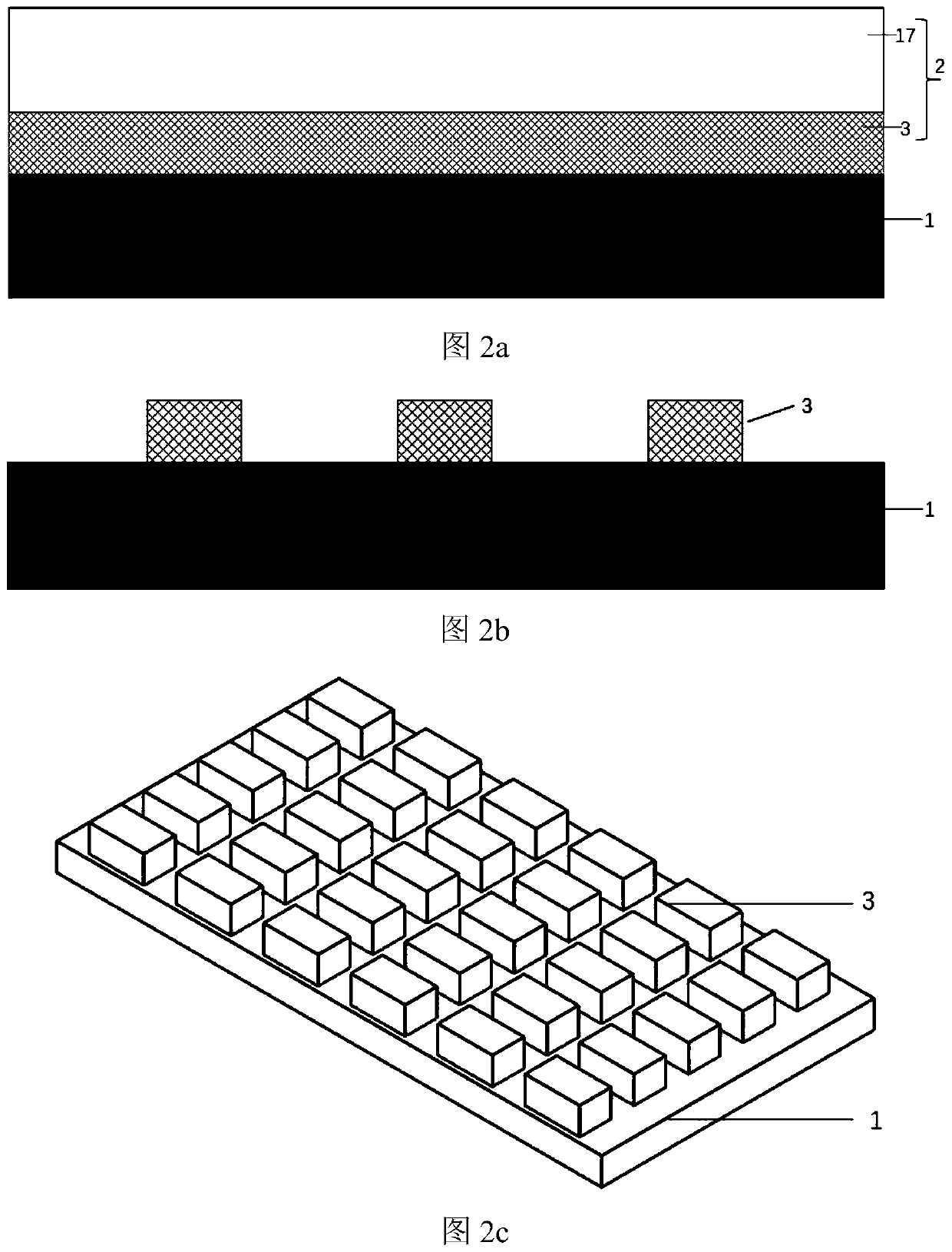

[0027] combine figure 2 a, after the GaN-based LED epitaxial wafer 2 on the sapphire substrate 17 and the Si-based CMOS active driving backplane 1 are bonded at the wafer level, after the sapphire substrate 17 is lifted off by laser, a single pixel can be prepared by ICP etching and other technologies Single-color Micro-LED array driven by independent addressing3, figure 2 b is a cross-sectional view of a monochromatic Micro-LED array, figure 2 c is the top view of the monochromatic Micro-LED array.

[0028] The preparation of the mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com