Modification method of hydrogen type mordenite molecular sieve for dimethyl ether carbonylation reaction

A carbonylation reaction, mordenite technology, applied in molecular sieve catalysts, chemical instruments and methods, carbon monoxide or formate reaction preparation, etc., can solve the problem of easy carbon deposition and deactivation on mordenite molecular sieves, reduced catalytic activity, and hinder industrial applications. and other problems, to achieve high catalytic stability and high selectivity, restore catalytic activity, and the method is simple and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Put H-MOR mordenite with a silicon-aluminum ratio of 5:1 into the reactor, and dry it at 300°C for 1 hour under Ar gas;

[0030] 2) The dried catalyst is cooled to 250° C., and 0.5% pyridine / He gas mixture is introduced until the catalyst is saturated with pyridine;

[0031] 3) After the adsorption of pyridine is saturated, N 2 The gas is heated to 300°C; at 300°C, N 2 Pyridine was desorbed under gas for 1 h to obtain mordenite molecular sieve MOR-250-300 selectively modified by pyridine.

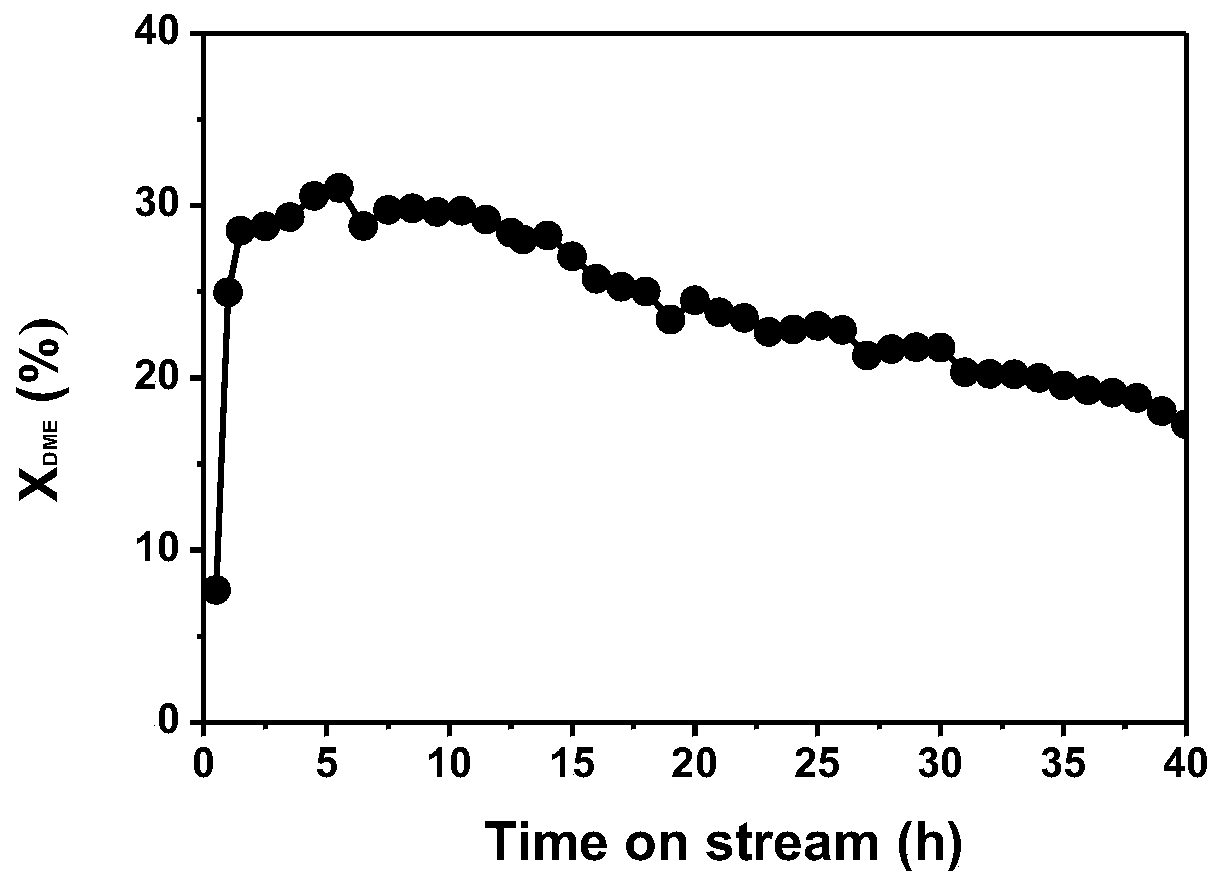

[0032] The catalyst is used for the carbonylation of dimethyl ether to produce methyl acetate, the reaction conditions are: the reaction pressure is 1.5MPa, the reaction gas composition is 3.0%DME / 95.5%CO / 1.5%N 2 , the space velocity is 5280mL (g h) -1 . The catalytic activity curve of the prepared MOR-250-300 catalyst for the carbonylation of dimethyl ether to produce methyl acetate is as follows figure 1 As shown, it can be seen from the figure that the conversion rate of d...

Embodiment 2

[0034] 1) Put H-MOR mordenite with a silicon-aluminum ratio of 6:1 into the reactor, 2 Dry under air at 500°C for 72 hours;

[0035] 2) Lower the temperature of the dried catalyst to 300°C, and feed in 2% pyridine / N 2 / Ar mixed gas until the catalyst adsorbs pyridine and saturates;

[0036] 3) After the adsorption of pyridine is saturated, N 2 The gas is heated to 400°C; at 400°C, N 2 Pyridine was desorbed under gas for 1 h to obtain mordenite molecular sieve MOR-300-400 selectively modified by pyridine.

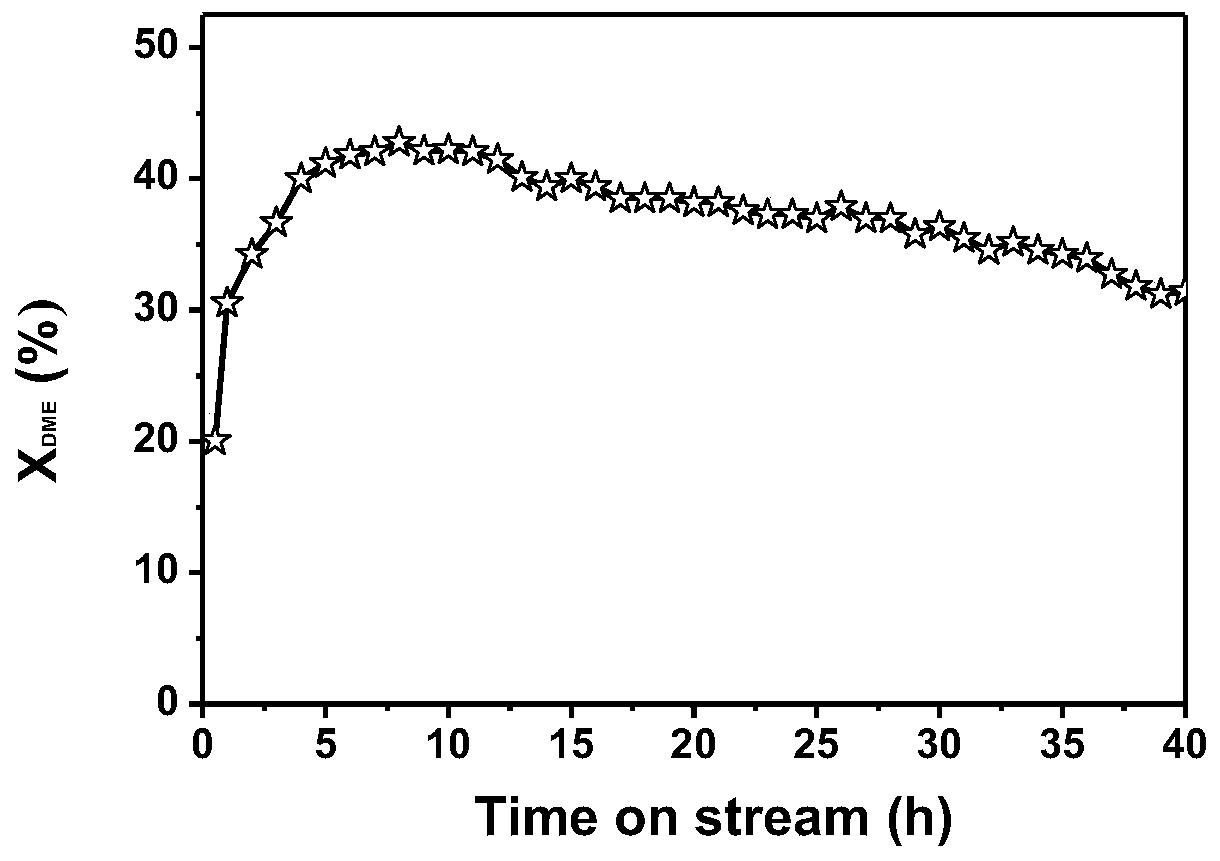

[0037] The catalyst is used for the carbonylation of dimethyl ether to produce methyl acetate. The reaction conditions are: the reaction pressure is 1.5MPa, and the reaction gas composition is 3.0%DME / 95.5%CO / 1.5%N 2 , the space velocity is 5280mL (g h) -1 . The catalytic activity curve of the prepared MOR-300-400 catalyst for the carbonylation of dimethyl ether to produce methyl acetate is as follows figure 2 As shown, it can be seen from the figure that the convers...

Embodiment 3

[0039] 1) Put H-MOR mordenite with a silicon-aluminum ratio of 16:1 into the reactor, and dry at 400°C for 96 hours under He gas;

[0040] 2) The dried catalyst is cooled to 350° C., and 2% pyridine / He gas mixture is introduced until the catalyst is saturated with pyridine;

[0041] 3) After the adsorption of pyridine is saturated, the temperature is raised to 400° C. by passing Ar gas; at 400° C., pyridine is desorbed under Ar gas for 1 h to obtain the mordenite molecular sieve MOR-350-400 selectively modified by pyridine.

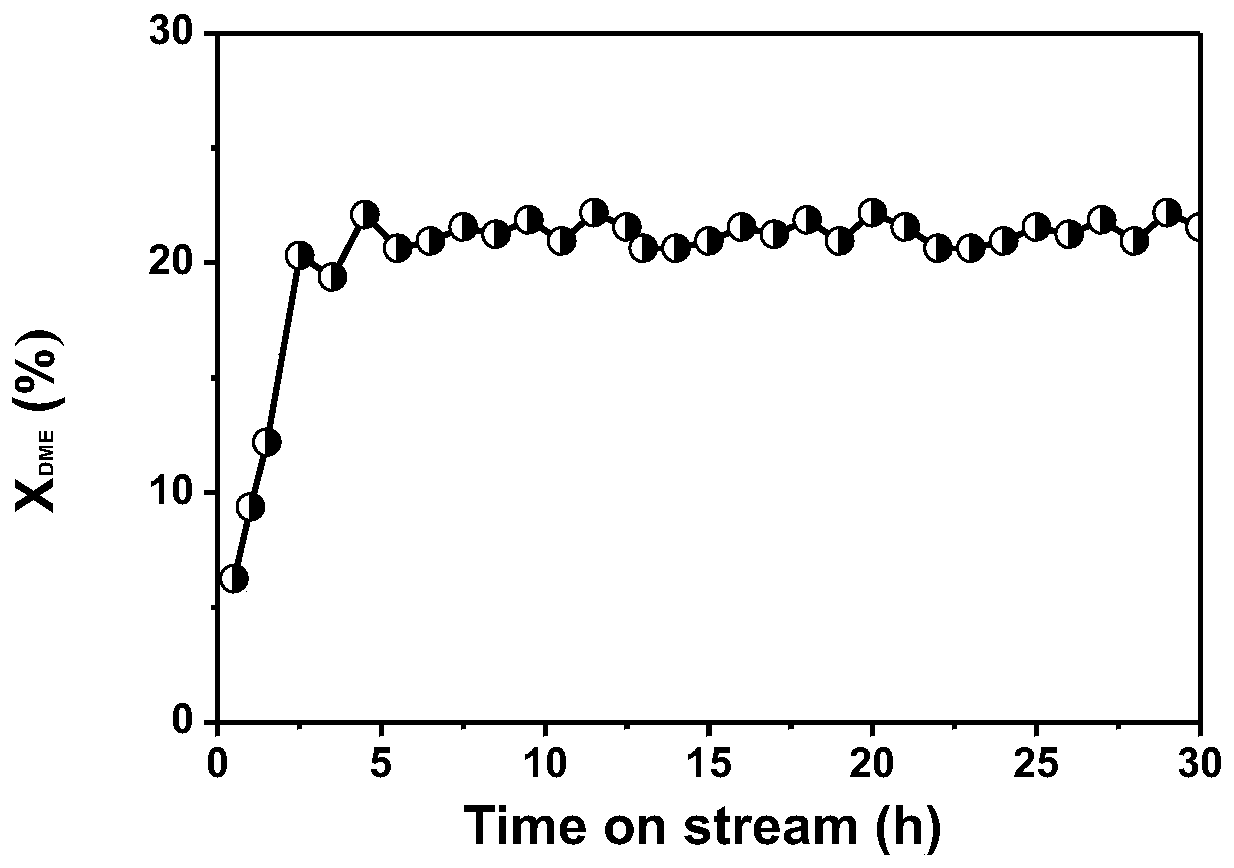

[0042] The catalyst is used for the carbonylation of dimethyl ether to produce methyl acetate. The reaction conditions are: the reaction pressure is 1.5MPa, and the reaction gas composition is 3.0%DME / 95.5%CO / 1.5%N 2 , the space velocity is 5280mL (g h) -1 . The catalytic activity curve of the prepared MOR-350-400 catalyst for the carbonylation of dimethyl ether to produce methyl acetate is as follows image 3 As shown, it can be seen from the figure tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com