Method for preparing ethanol by semi-continuous fermentation of surface-immobilized yeast

An immobilized yeast, semi-continuous technology, applied in biochemical equipment and methods, methods based on microorganisms, immobilized on/in organic carriers, etc., can solve the problems of poor ethanol production and avoid easy staining Bacteria, high efficiency, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

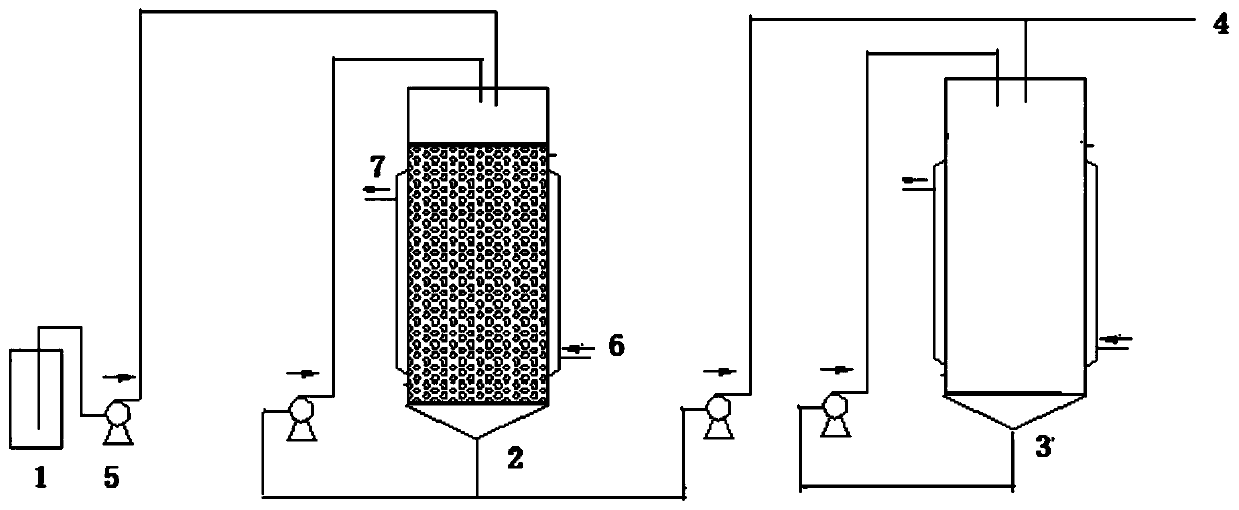

[0041] Example 1 Using synthetic medium as fermentation raw material and adopting bamboo fiber immobilized yeast semi-continuous fermentation to produce fuel ethanol

[0042] First, fix cotton fibers (thickness 0.22 cm) cut to a side length of 2.5 cm on a polypropylene figure 1 Prepare the immobilization medium on the central axis of the spherical grid with a diameter of 4.5cm (the side length of the ball hole is 0.8cm); then put the immobilization medium into a 100L reactor with a filling amount of 2g / L middle. Then the cultured strains were added to the fermenter, and fixed at a flow rate of 80 L / min for 42 hours. Until the bacterial cell adsorption concentration is 200 million / ml. Then drain to waste. Then feed the fermentation medium (glucose concentration is 220g / L, fermentation broth pH4.2), the liquid loading volume is 75%, carry out circulation fermentation, wherein temperature is 34 ℃, flow rate is 800L / h. The concentration of free yeast in the solution dropped to...

Embodiment 2

[0043] Example 2 Using cassava liquefied mash medium as fermentation raw material, bamboo fiber immobilized yeast was used for semi-continuous fermentation to produce fuel ethanol.

[0044] First, fix the column fiber (thickness 0.2cm) cut into a diameter of 18cm in a spherical grid with a diameter of 25cm (the side length of the ball hole is 5cm) made of polyethylene as shown in the figure, and prepare the immobilization medium; then fix the Put the chemical medium into a 20-ton reactor with a height-to-diameter ratio of 2.5:1 with a filling amount of 2.2g / L. Then the cultured strains were added to the fermenter, and fixed at a flow rate of 20 tons m3 / h for 48 hours. Until the concentration of free bacteria in the solution drops by about 182 million cells / ml. Then prepare cassava liquefied mash: the ratio of solid to liquid is 1:2.4, add liquefaction enzyme (15U / g cassava dry weight) to liquefy at 85°C for 2 hours, press filter, and discharge the immobilized seed waste liqui...

Embodiment 3

[0045] Example 3 Using molasses medium as fermentation raw material to carry out semi-continuous fermentation of immobilized yeast to produce fuel ethanol

[0046]At first, carrier preparation and immobilization method (using total sugar 180g / l molasses as seed medium) are the same as in Example 2. After the fixation ends, the acidified molasses is diluted to a sugar concentration of 245g / L and pumped into the immobilized fermenter for Circular fermentation, wherein the temperature is 35°C, the pH of the fermentation broth is 4.0, and the flow rate is 10m3 / h. Stable during the third batch of fermentation, and the concentration of free bacteria is 0.85 billion / ml, and when the alcohol content reaches 10% (v / v), discharge 50% of the material to an empty tank for post-fermentation, and then feed to the original volume, and continue Draining to the empty tank previously filled with 40% broth, after filling the tank, the immobilized fermenter broth is pumped into the second empty t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com