Preparation method, product and application of porous fibers with oriented pore structures

A technology of porous fiber and pore structure, which is applied in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of limiting the application of porous fiber and the inability to realize continuous large-scale preparation, and achieve excellent heat insulation performance and preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Cut 4.5g of natural cocoons, boil and dry in 1% sodium carbonate solution, dissolve in 20ml of 9mol / ml lithium bromide solution, dialyze for 24h to prepare 22.5% silk protein solution.

[0046] Dissolve 0.5g of chitosan powder in 10ml of 1% acetic acid solution, stir at 800rpm / min for 30min to mix evenly, and prepare 5% chitosan solution.

[0047] Mix 20ml of silk protein solution and 10ml of chitosan solution evenly, and centrifuge to remove air bubbles to obtain a homogeneous solution, wherein the mass ratio of silk protein to chitosan is 9:1.

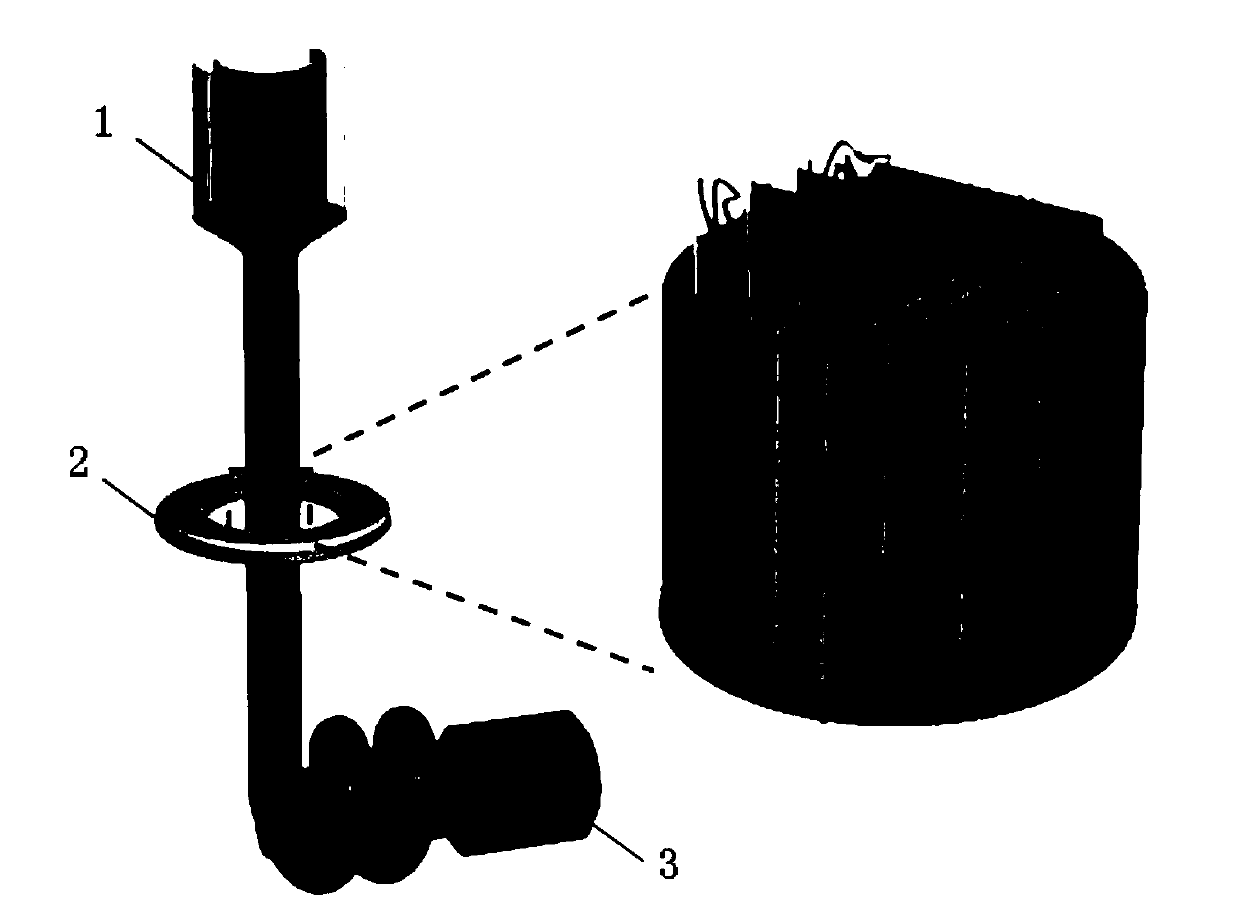

[0048] (2) Put the mixed solution in the syringe, extrude the solution through the extrusion pump, place the copper ring in a low-temperature reaction bath (-100°C), and pass the solution through the copper ring for freezing-spinning process, and the frozen Motorized collection of fibers

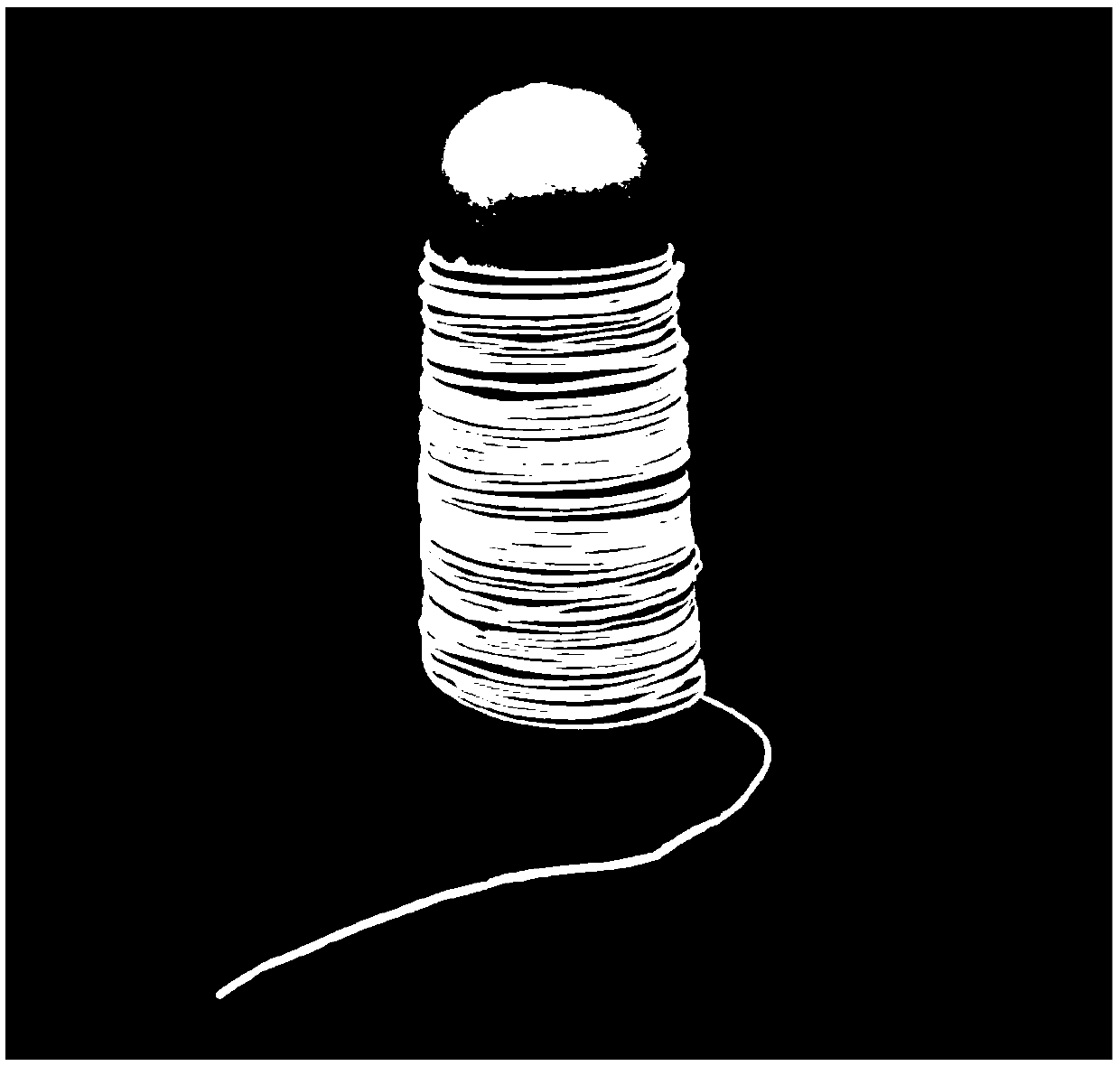

[0049] (3) Freeze-dry the frozen fiber obtained in step (2) for 24h to remove the solvent to obtain a porous fiber with an oriented po...

Embodiment 2

[0053] (1) Cut 4.5g of natural cocoons, boil and dry in 1% sodium carbonate solution, dissolve in 20ml of 9mol / ml lithium bromide solution, dialyze for 24h to prepare 22.5% silk protein solution.

[0054] Dissolve 0.5g of chitosan powder in 10ml of 1% acetic acid solution, stir at 800rpm / min for 30min to mix evenly, and prepare 5% chitosan solution.

[0055] After mixing 20ml of silk protein solution and 10ml of chitosan solution evenly, centrifuge to remove air bubbles to obtain a homogeneous solution, wherein the mass ratio of silk protein to chitosan is 9:1.

[0056] (2) Put the mixed solution in the syringe, extrude the solution through the extrusion pump, place the copper ring in a low temperature reaction bath (-40, -60, -80, -100°C respectively), and pass the solution through the copper ring Freezing-spinning process, and the frozen fibers are collected by motor.

[0057] (3) Freeze-drying the frozen fiber obtained in step (2) for 24 hours to remove the solvent to obta...

Embodiment 3

[0061] (1) Cut 4.5g of natural cocoons, boil and dry in 1% sodium carbonate solution, dissolve in 20ml of 9mol / ml lithium bromide solution, dialyze for 24h to prepare 22.5% silk protein solution.

[0062] Dissolve 0.5g of chitosan powder in 10ml of 1% acetic acid solution, stir at 800rpm / min for 30min to mix evenly, and prepare 5% chitosan solution.

[0063] Dissolve 0.01g of carbon nanotube powder in 10ml of 1% sodium dodecylbenzenesulfonate solution, mix 20ml of silk protein solution, 10ml of chitosan solution and 20ml of carbon nanotube solution, and centrifuge to remove air bubbles to obtain A homogeneous solution, wherein the mass ratio of silk protein to chitosan is 9:1, and the mass ratio of silk protein to carbon nanotubes is 225:1.

[0064] (2) Put the mixed solution in the syringe, extrude the solution through the extrusion pump, place the copper ring in a low-temperature reaction bath (the temperature is -100°C), pass the solution through the copper ring for freezin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com