Tunnel kiln waste gas treatment system and method

A technology of waste gas treatment and treatment method, which is applied in the field of waste gas treatment system of tunnel kiln (especially brick kiln), which can solve the problems of not being able to meet environmental protection, affecting the production efficiency of brick kiln, and polluting the surrounding environment, so as to ensure the quality of roasting and the overall economy. Significant value and environmental value, the effect of efficient drying treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

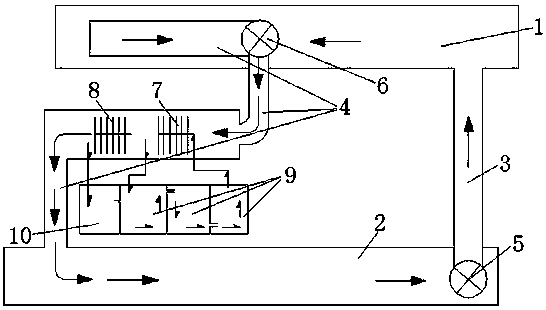

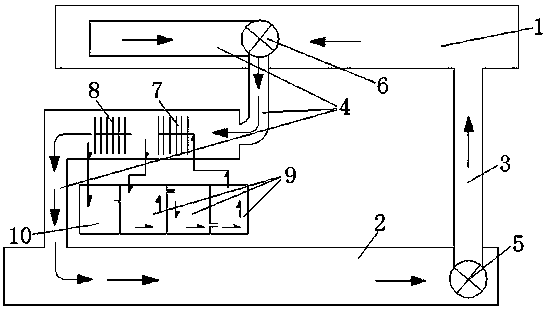

[0026] see figure 1As shown, the brick kiln of the present invention includes a drying kiln 1 and a roasting kiln 2 with relatively independent kiln bodies. Among them, there are two sets of mutually independent gas conveying channels at the top of the kiln between the drying kiln 1 and the roasting kiln 2, that is, one set (usually one, of course, depending on the production scale, multiple sets) are the roasting side gas passages. Conveying channel 3, the other group (usually one, of course, can be set up according to the production scale) is the gas conveying channel 4 on the drying side; the gas conveying channel 3 on the roasting side is used to send the gas mixture in the roasting kiln 2 into the oven In the dry kiln 1, in order to ensure the reliability of the gas flow, a fan one 5 is installed on the gas delivery channel 3 on the roasting side, and the fan one 5 is usually located in the gas inlet area of the gas delivery channel 3 on the roasting side—that is, in th...

Embodiment 2

[0035] The brick kiln of the present invention includes a drying kiln and a roasting kiln with relatively independent kiln bodies. Among them, there are two sets of independent gas delivery channels at the top of the kiln between the drying kiln and the roasting kiln, that is, one group (usually one, of course, depending on the production scale, multiple channels) are the gas delivery channels on the roasting side. , the other group (usually one, of course, can be set up multiple depending on the scale of production) is the gas delivery channel on the drying side; the gas delivery channel on the roasting side is used to send the gas mixture in the roasting kiln into the drying kiln, in order to ensure For the reliability of gas flow, fan 1 is installed on the gas conveying channel on the roasting side, and the fan 1 is usually located in the gas inlet area of the gas conveying channel on the roasting side—that is, in the roasting kiln; the gas conveying channel on the drying ...

Embodiment 3

[0044] The other content of this embodiment is the same as that of Embodiment 1 or 2, except that: the fan on the gas delivery channel on the roasting side is installed in the middle area of the gas delivery channel on the roasting side—that is, between the roasting kiln and the drying kiln; The second blower on the dry side gas delivery channel is installed in the middle area of the dry side gas delivery channel—that is, between the drying kiln and the roasting kiln.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com