Trauma hemostatic sponge and preparing method and application thereof

A hemostatic sponge, trauma technology, applied in the field of hemostasis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a preparation method of the trauma hemostatic sponge described in the above technical solution, comprising the following steps:

[0036] Freeze-drying the zeolite-graphene oxide composite hydrogel to obtain the zeolite-graphene composite aerogel;

[0037] The zeolite-graphene composite airgel is sequentially subjected to microwave expansion and high temperature treatment to obtain a trauma hemostatic sponge.

[0038] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0039] The invention freeze-dries the zeolite-graphene oxide hydrogel to obtain the zeolite-graphene composite airgel.

[0040] In the present invention, the preparation method of the zeolite-graphene oxide composite hydrogel comprises the following steps: mixing a graphene oxide solution, a crosslinking agent and zeolite, and performing a crosslinking reaction to...

Embodiment 1

[0057] Mix 100mg of zeolite powder, 20mL of graphene oxide solution (5mg / mL) and 0.2mL of ethylenediamine (0.90g / mL) and react at 96°C for 6h to obtain a zeolite-graphene oxide composite hydrogel ;

[0058] Freeze-dry the zeolite-graphene composite hydrogel at -45°C for 48 hours, wash the freeze-dried product with ethanol in a Soxhlet extractor for 48 hours, and dry it at 25°C for 48 hours to obtain the zeolite-graphene gas gel;

[0059] The zeolite-graphene airgel was expanded with 800W microwave for 10s, and treated at 100°C for 1 hour to obtain a trauma hemostatic sponge (the mass ratio of zeolite powder and graphene was 7:20), which could be directly used for trauma hemostasis;

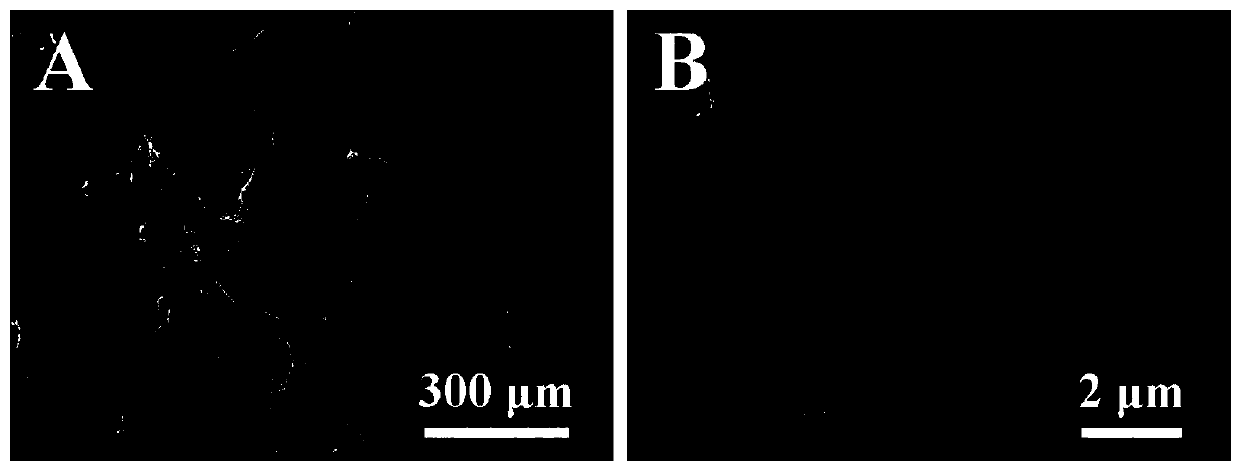

[0060] The described trauma hemostatic sponge is carried out SEM test, test result is as follows figure 1 Shown (Figure B is a 100-fold magnification of Figure A), by figure 1 It can be seen that the graphene in the trauma hemostatic sponge of the present invention has a three-dimensional cross...

Embodiment 2

[0062] Mix 200mg zeolite powder, 20mL graphene oxide solution (5mg / mL) and 0.2mL ethylenediamine (0.90g / mL) and react at 96°C for 6h to obtain zeolite-graphene oxide composite hydrogel ;

[0063] Freeze-dry the zeolite-graphene composite hydrogel at -45°C for 48 hours, wash the freeze-dried product with ethanol in a Soxhlet extractor for 48 hours, and dry it at 25°C for 48 hours to obtain the zeolite-graphene gas gel;

[0064] The zeolite-graphene airgel was expanded by 800W microwave for 20s, and treated at 100°C for 2 hours to obtain a trauma hemostatic sponge (the mass ratio of zeolite powder to graphene was 7:3), which could be directly used for trauma hemostasis.

[0065] The SEM test results of the trauma hemostatic sponge are similar to the examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com