Preparation method of storage stability foam fire extinguishing agent material

A technology of foam fire extinguishing agent and storage stability, which is applied in the field of preparation of storage stable foam fire extinguishing agent materials, which can solve the problems of short storage time, corruption, and environmental pollution of foam fire extinguishing agents, and achieve excellent fire extinguishing effect, increased rheology, The effect of improving structural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

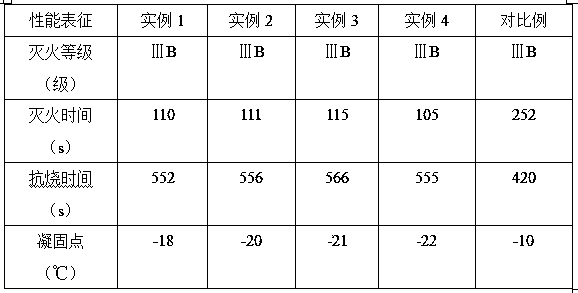

Examples

Embodiment Construction

[0030] Take camphor leaves and wash and dry them, pulverize them and place them in a supercritical carbon dioxide extraction device. The extraction pressure is 25-28MPa, the extraction temperature is 45-50°C, the flow rate of carbon dioxide is 1.7-2.0L / min, and the separation temperature After static extraction at 52°C for 45-50 minutes, the extract was collected and filtered, and the filtrate was collected to obtain the modified essential oil; in parts by weight, weigh 40-45 parts of modified essential oil and 25-30 parts of 85% ethanol The solution and 6 to 8 parts of 30% sulfuric acid solution by mass fraction were placed in a beaker, stirred and mixed, and placed at 55 to 60°C for 3 to 5 hours of heat preservation reaction, left to cool to room temperature, and the reaction liquid was obtained and placed in a separatory funnel. Stand to separate layers and collect the upper oil phase, adjust the pH to 7.0 with saturated sodium bicarbonate solution at room temperature, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com