Preparation method of inorganic non-noble metal Ni doped Cu-based bifunctional electrocatalyst

An electrocatalyst and noble metal technology, which is applied in the field of preparation of inorganic non-noble metal Ni-doped Cu-based bifunctional electrocatalysts, can solve the problems of time-consuming, complicated, and unsuitable for large-scale industrial applications, and achieve excellent hydrogen evolution and oxygen evolution performance , The effect of simple synthesis and preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

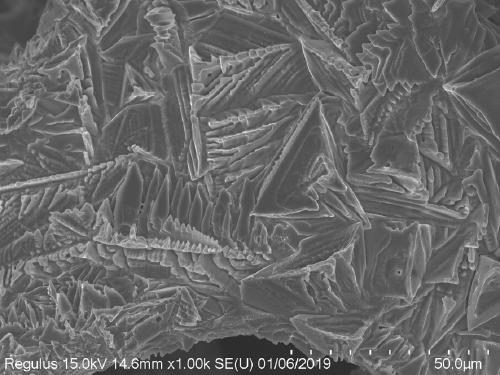

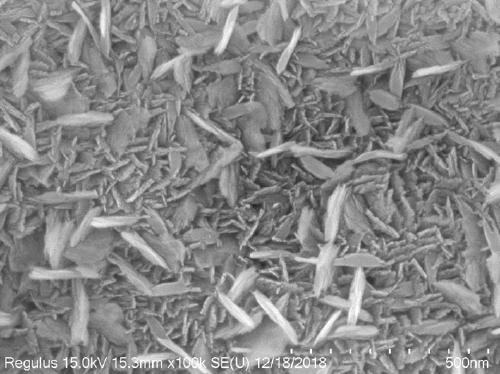

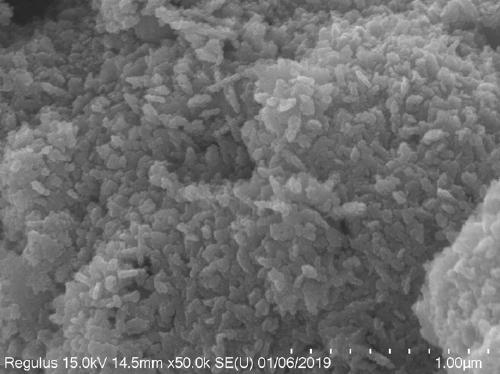

Image

Examples

Embodiment Construction

[0029] A preparation method of inorganic non-noble metal Ni-doped Cu-based bifunctional electrocatalyst, the steps are as follows:

[0030] 1. Mix copper sulfate and hydrochloric acid according to a certain concentration ratio, and stir evenly to obtain a mixed solution;

[0031] 2. Place the cleaned foamed nickel in a mixed solution of copper sulfate and hydrochloric acid at room temperature;

[0032] 3. After standing still, take out the nickel foam, rinse it in absolute ethanol several times, and then dry it with cold air;

[0033] 4. Place the product in step 3 in KOH solution for in-situ electrochemical oxidation. After the reaction, take out the sample and wash it several times with deionized water, and dry it with cold air for later use;

[0034] 5. After electrochemical oxidation, place the sample in step 4 in KOH solution for oxygen evolution reaction;

[0035] 6. Prepare a certain concentration of sodium sulfide solution for use;

[0036] Seven, the product to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com