SnS2/1T-MoS2QDS composite photocatalyst and preparation method and application thereof

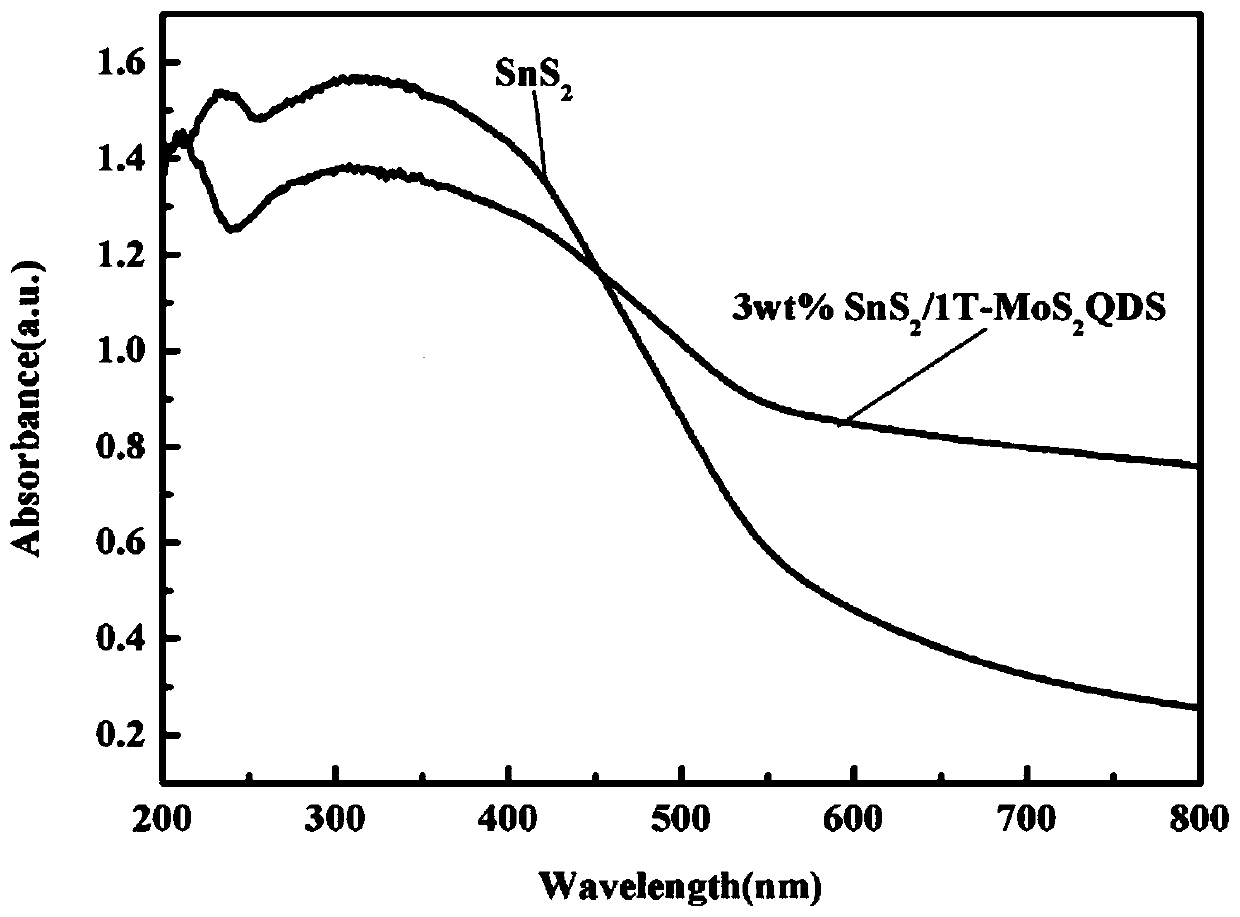

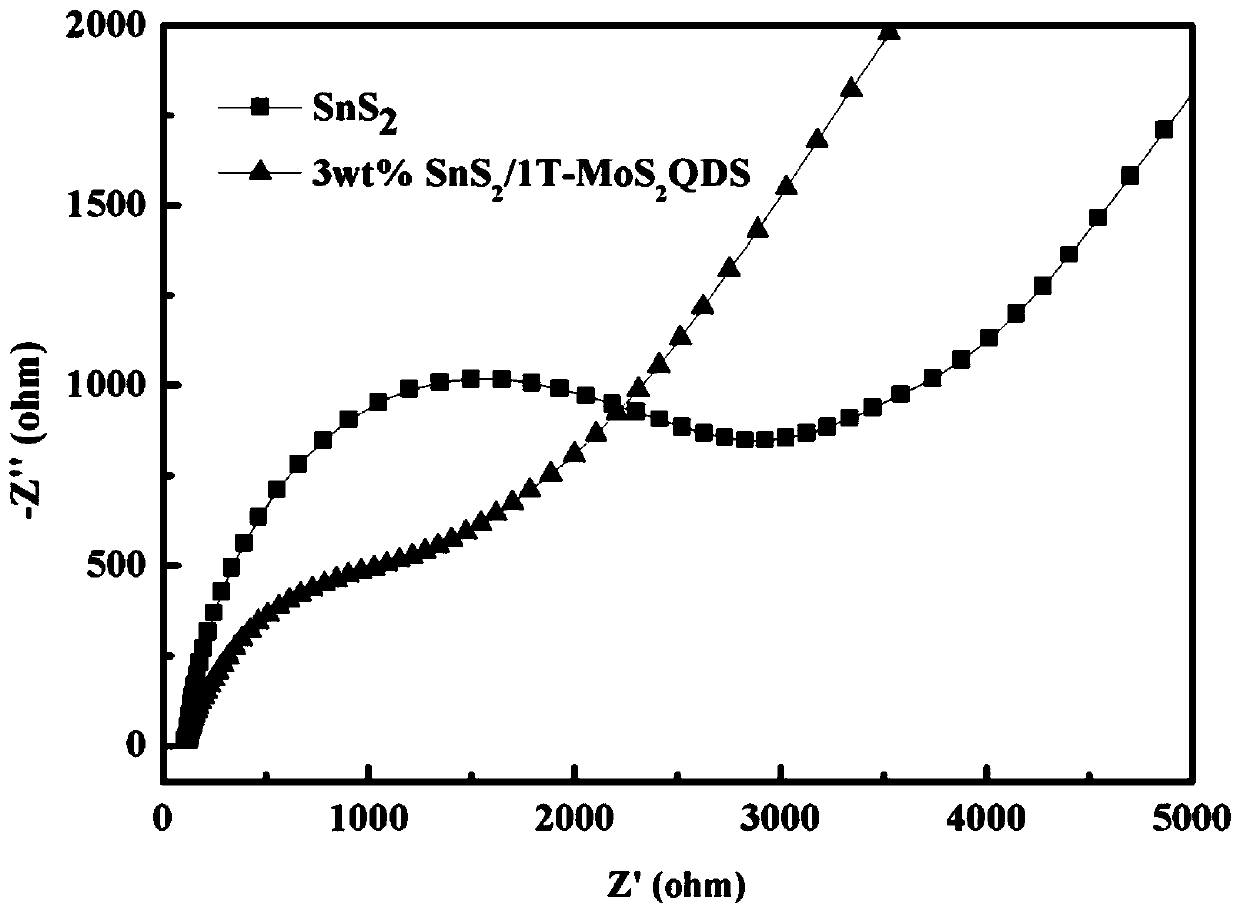

A technology of catalyst and recombination of light, which is applied in the field of photocatalytic materials, can solve the problems of high recombination rate of photogenerated carriers, low utilization rate of visible light, and low photocatalytic activity, so as to improve light absorption capacity, reduce recombination rate, and high catalytic efficiency active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

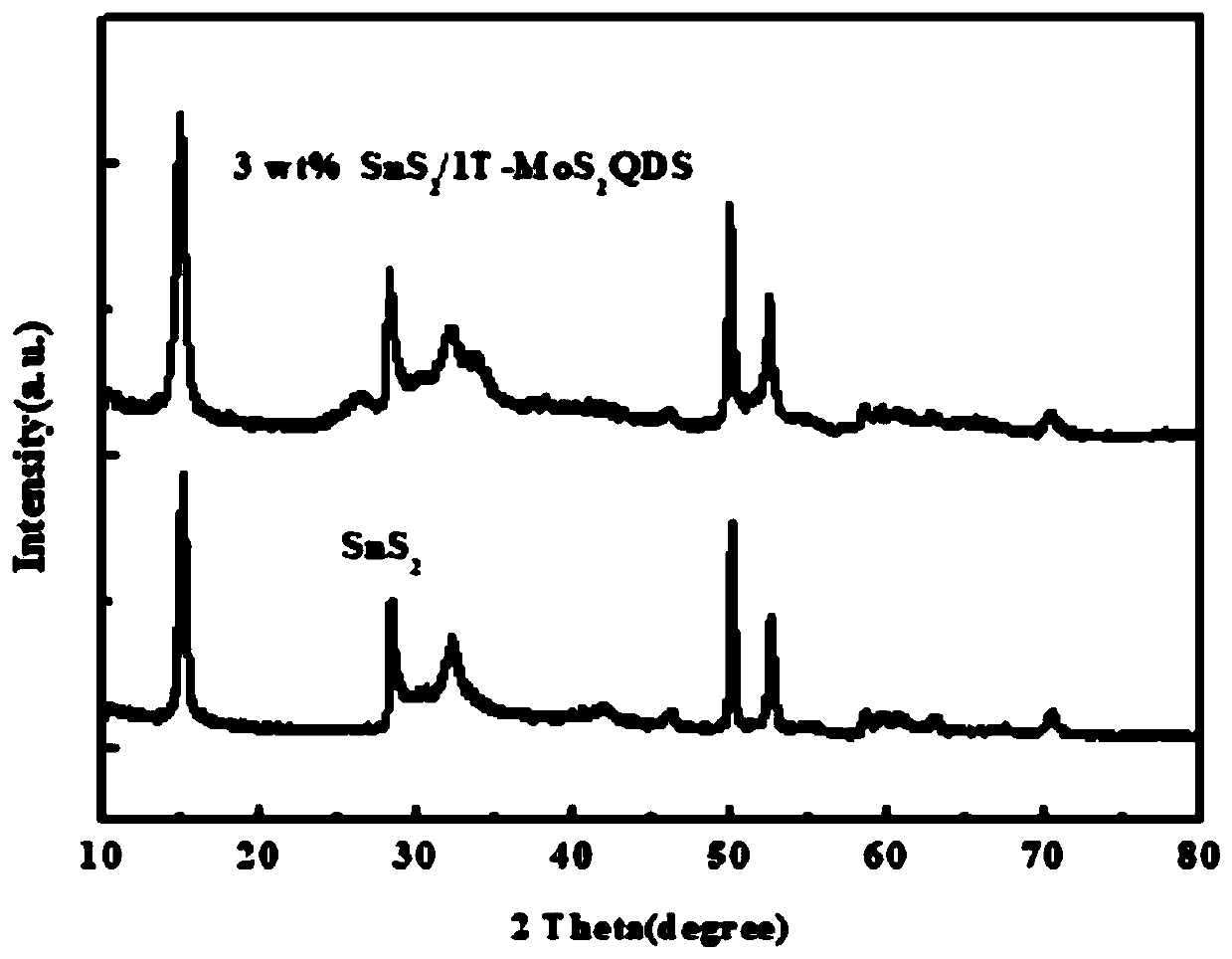

[0037] A kind of SnS 2 / 1T-MoS 2 QDS composite photocatalysts including SnS containing S-vacancy defects 2 Nanosheets and loaded on SnS 2 1T-MoS on nanosheets 2 QDS, 1T-MoS 2 QDS and SnS 2 Nanosheets form heterojunctions, and 1T-MoS 2 The weight ratio of QDS in the composite photocatalyst is 1%.

[0038] The specific preparation method is as follows:

[0039] Step 1, weigh 5mmol SnCl 4 ·5H 2O and 5mmol of citric acid were dissolved in 40mL of ultrapure water, and magnetically stirred for 30min; then 5mmol of L-cysteine was added, and the stirring was continued for 1h. In an ethylene-lined autoclave, place it in an oven at 150°C for hydrothermal reaction for 12 hours. After the reaction, a yellow solid precipitates, which is washed by centrifugation and dried at 60°C for 12 hours to obtain SnS 2 Nanosheets;

[0040] Step 2, 1mmol Na 2 MoO 4 2H 2 O was sonicated in 30mL ultrapure water for 30min to obtain Na 2 MoO 4 2H 2 O aqueous solution;

[0041] Sonicate ...

Embodiment 2

[0048] A kind of SnS 2 / 1T-MoS 2 QDS composite photocatalysts including SnS containing S-vacancy defects 2 Nanosheets and loaded on SnS 2 1T-MoS on nanosheets 2 QDS, 1T-MoS 2 QDS and SnS 2 Nanosheets form heterojunctions, and 1T-MoS 2 The weight ratio of QDS in the composite photocatalyst is 3%.

[0049] The specific preparation method is as follows:

[0050] Step 1, weigh 5mmol SnCl 4 ·5H 2 O and 5 mmol citric acid, dissolved in 40 mL ultrapure water, stirred magnetically for 30 min, then added 8.75 mmol thioacetamide, continued stirring for 4 h, then, transferred to a 100 mL autoclave lined with Teflon placed in an oven at 150°C for hydrothermal reaction for 12 hours, and a yellow solid precipitate was obtained after the reaction, which was washed by centrifugation and dried at 60°C for 12 hours to obtain SnS 2 Nanosheets;

[0051] Step 2, 1mmol Na 2 MoO 4 2H 2 O was sonicated in 30mL ultrapure water for 30min to obtain Na 2 MoO 4 2H 2 O aqueous solution;

...

Embodiment 3

[0058] A kind of SnS 2 / 1T-MoS 2 QDS composite photocatalysts including SnS containing S-vacancy defects 2 Nanosheets and loaded on SnS 2 1T-MoS on nanosheets 2 QDS, 1T-MoS 2 QDS and SnS 2 Nanosheets form heterojunctions, and 1T-MoS 2 The weight ratio of QDS in the composite photocatalyst is 3%.

[0059] The specific preparation method is as follows:

[0060] Step 1, weigh 5mmol SnCl 4 ·5H 2 0 and 5mmol citric acid, dissolved in 40mL ultrapure water, stirred magnetically for 30min, then added 10mmol sodium sulfide, continued to stir for 5h, then transferred it to a 100mL autoclave lined with polytetrafluoroethylene, placed Put it in an oven at 180°C for hydrothermal reaction for 12 hours. After the reaction, a yellow solid precipitate was obtained, which was washed by centrifugation and dried at 60°C for 12 hours to obtain SnS 2 Nanosheets;

[0061] Step 2, ultrasonicating 1mmol ammonium molybdate in 30mL ultrapure water for 30min to obtain ammonium molybdate aqueou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com