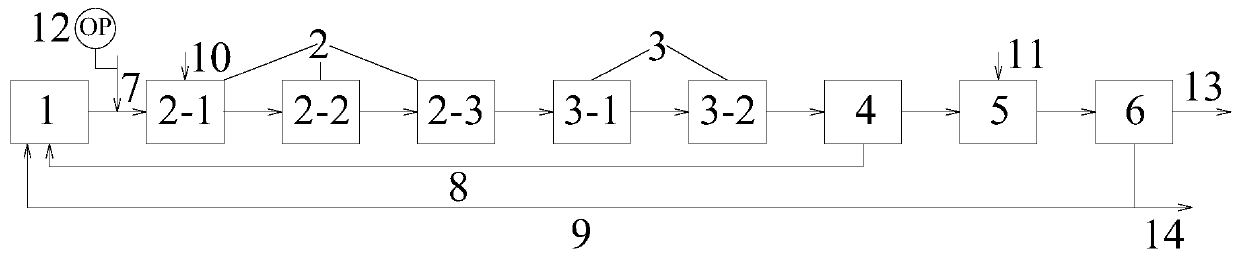

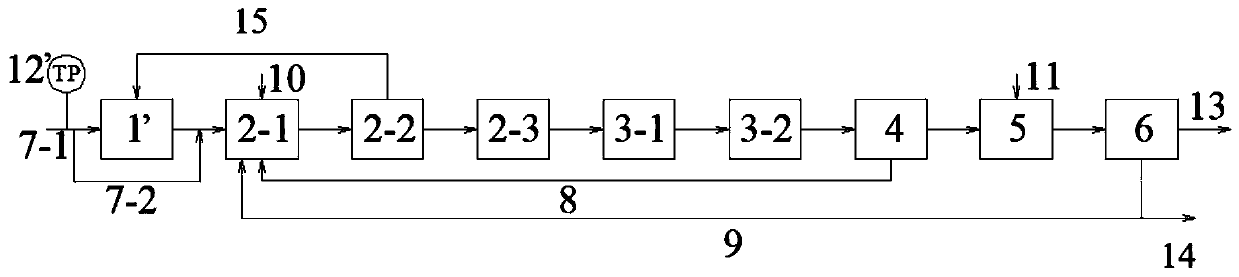

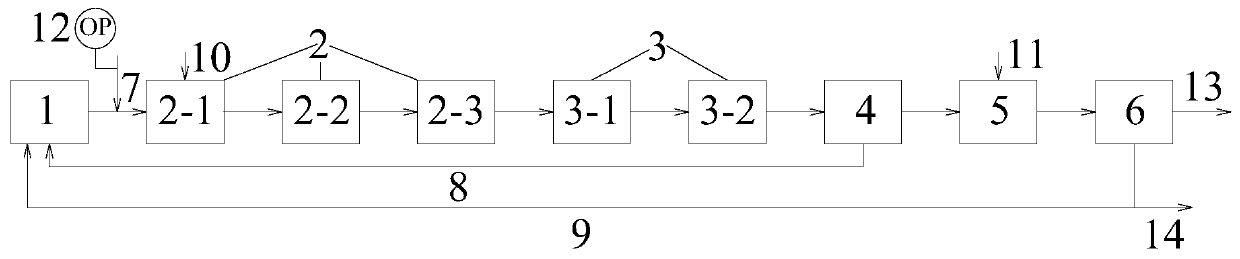

Sewage treatment optimization operation system based on changing anaerobic tank into enhanced degassing zone

A technology for sewage treatment and optimized operation, which is applied in the fields of degassed water/sewage treatment, water/sewage treatment, biological water/sewage treatment, etc., which can solve the problem of insufficient carbon source in influent water, high carbon source dosage and high dosage. , large ineffective loss of carbon sources, etc., to achieve the effect of increasing the actual hydraulic retention time, reducing the cost of carbon source addition, and reducing the cost of carbon source addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for optimizing the operation of sewage treatment in industrial parks based on changing the anaerobic tank to an enhanced degassing zone, comprising the following steps:

[0046] a. The return sludge of the sludge return system and the return nitrification liquid of the nitrification liquid return system enter the enhanced degassing zone together, stay for 1.5 hours under stirring conditions, and carry out the activated sludge under the action of microorganisms (MLSS is 5g / L) DO is removed by the biological oxidation reaction of source organic matter or surface-adsorbed organic matter, wherein the return flow of sludge is 1 times of sewage flow, and the return flow of nitrification liquid is 2 times of sewage flow;

[0047] B, step a gained enhanced degassing zone mixed solution and the whole biological pond inlet system of pretreatment enter the first anoxic pond 2-1 together, stay 1.5 hours under anoxic stirring condition, in microorganism (MLSS is 4g / L) unde...

Embodiment 2

[0055] A method for optimizing the operation of sewage treatment in industrial parks based on changing the anaerobic tank to an enhanced degassing zone, comprising the following steps:

[0056] a. The return sludge of the sludge return system and the return nitrification liquid of the nitrification liquid return system enter the enhanced degassing zone together, stay for 1 hour under stirring conditions, and activate the sludge under the action of microorganisms (MLSS is 4.5g / L) DO is removed by the biological oxidation reaction of endogenous organic matter or organic matter adsorbed on the surface, wherein the return flow of sludge is 1 times of the flow of sewage, and the return flow of nitrification liquid is 1 time of flow of sewage;

[0057] B, step a gained enhanced degassing zone mixed solution and the whole biological pond inlet system of pretreatment enter first anoxic pond 2-1 together, stay 1 hour under anoxic stirring condition, in microorganism (MLSS is 3g / L) und...

Embodiment 3

[0065] A method for optimizing the operation of sewage treatment in industrial parks based on changing the anaerobic tank to an enhanced degassing zone, comprising the following steps:

[0066] a. The return sludge of the sludge return system and the return nitrification liquid of the nitrification liquid return system enter the enhanced degassing zone together, stay under stirring conditions for 1 hour, and carry out activated sludge under the action of microorganisms (MLSS is 6g / L) DO is removed by the biological oxidation reaction of source organic matter or organic matter adsorbed on the surface, wherein the return flow of sludge is 0.5 times of the sewage flow, and the return flow of nitrifying liquid is twice of the sewage flow;

[0067] B, step a gained enhanced degassing zone mixed solution and the whole biological pond inlet system of pretreatment enter first anoxic pond 2-1 together, stay 1 hour under anoxic stirring condition, in microorganism (MLSS is 4g / L) under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com