Preparation method of flame-retardant superhydrophobic sponge with photothermal effect and magnetic driving function

A technology of superhydrophobic sponge and photothermal effect, which is applied in the field of preparation of superhydrophobic sponge with photothermal effect and magnetically driven flame retardant, can solve the problems of flammability safety hazards of sponge materials, cumbersome operation steps, complex synthesis process and other problems, and achieve excellent Oil-water separation ability, simple process and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The method for preparing a flame-retardant superhydrophobic sponge with photothermal effect and magnetic drive according to an embodiment of the present invention includes the following steps:

[0027] Step 10) Pretreating the melamine sponge: immerse the melamine sponge in deionized water, take it out to dry after ultrasonic cleaning, then immerse it in an organic solvent for ultrasonic cleaning, and dry to obtain a pretreated melamine sponge.

[0028] Preferably, the porosity of the melamine sponge is 98-99.5 %. The high porosity of the melamine sponge allows the sponge to absorb more oil. In step 10), the pretreatment cleans off the dust and the like on the surface of the sponge to prevent pollutants from clogging the sponge holes and prevent the modification and oil absorption performance from being affected.

[0029] Step 20) Preparation of nano-magnetic particles and silicone resin (hereinafter referred to as PDMS) treatment solution: Add PDMS prepolymer into organic so...

Embodiment 1

[0040] The whole melamine sponge with a porosity of 98% is immersed in deionized water, ultrasonically cleaned, and taken out to dry, then immersed in ethanol for ultrasonic cleaning, and dried to obtain a pretreated melamine sponge.

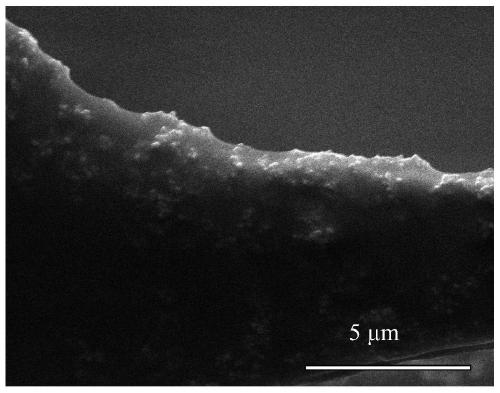

[0041] Take 0.1g Sylgard 184 prepolymer and add it to 80mL acetone / ethyl acetate, and magnetically stir for 10min, then add 0.01g curing agent, and stir for 10min to make it evenly dispersed; then under mechanical stirring and ultrasonic dispersion, 5g60nmFe 2 0 3 Add 3.5g of 100nm iron particles into the PDMS resin solution, stir and ultrasonic for 30min to prepare magnetic particles and PDMS treatment solution.

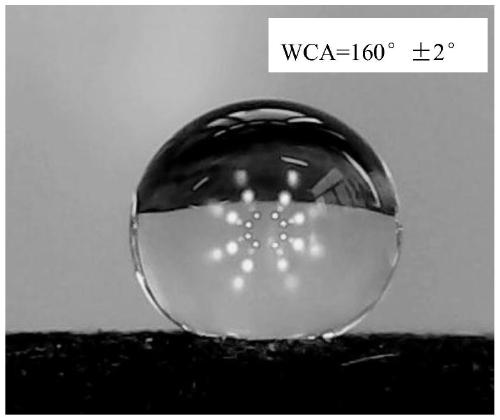

[0042] Soak the pretreated melamine sponge in the magnetic particles and PDMS treatment solution, and ultrasonically treat it for 1 min, squeeze the excess treatment solution out of the melamine sponge, and then vacuum dry the soaked melamine sponge at 40°C 3h, that is, a superhydrophobic sponge with photothermal effect and magnetically dri...

Embodiment 2

[0045] The whole melamine sponge with a porosity of 99% is immersed in deionized water, taken out after ultrasonic cleaning, and dried, then immersed in acetone for ultrasonic cleaning, and dried to obtain a pretreated melamine sponge. Take 3g of Sylgard 182 prepolymer and add it to 100mL of heptane, and magnetically stir for 15min, then add 0.3g of curing agent, and stir for 10min to make it evenly dispersed; then under mechanical stirring and ultrasonic dispersion, 0.08g10nmFe 2 O 3 Add 0.04g of 100nm iron particles into the PDMS resin solution, stir and ultrasonic for 60 minutes to prepare nano magnetic particles and PDMS treatment solution.

[0046] Soak the pretreated melamine sponge in the nano magnetic particles and PDMS treatment solution, ultrasonically treat it for 2 minutes, squeeze the excess treatment solution out of the melamine sponge, and then vacuum dry the soaked melamine sponge at 70°C After 10 hours, a superhydrophobic sponge with photothermal effect and magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com