Temperature-controlled structural color dye, and preparation and application thereof

A structural color and dye technology, which is applied to temperature-controlled structural color dyes and their preparation and application fields, to achieve the effects of reducing fluidity and environmental loss, good temperature control performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Using the emulsion polymerization method, prepare a monodisperse polystyrene-polymethyl methacrylate-polyacrylic acid solution with a particle size of 100nm as the shell and paraffin as the core. The aqueous solution of the core-shell structure latex particles; 0.1wt% and ultrasonically dispersed uniformly, then the polyester fabric is immersed in the above mixed solution, self-assembled at a temperature of 20°C and a humidity of 10% to obtain a structural color dye with temperature control properties on the surface of the polyester fabric.

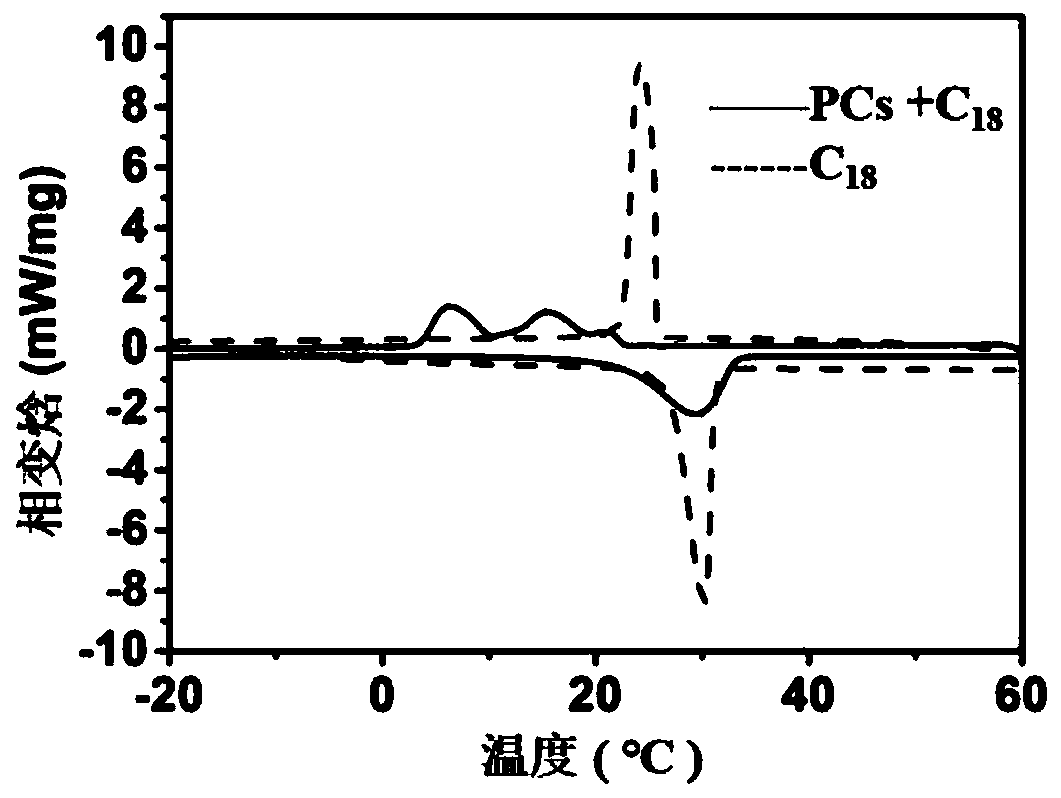

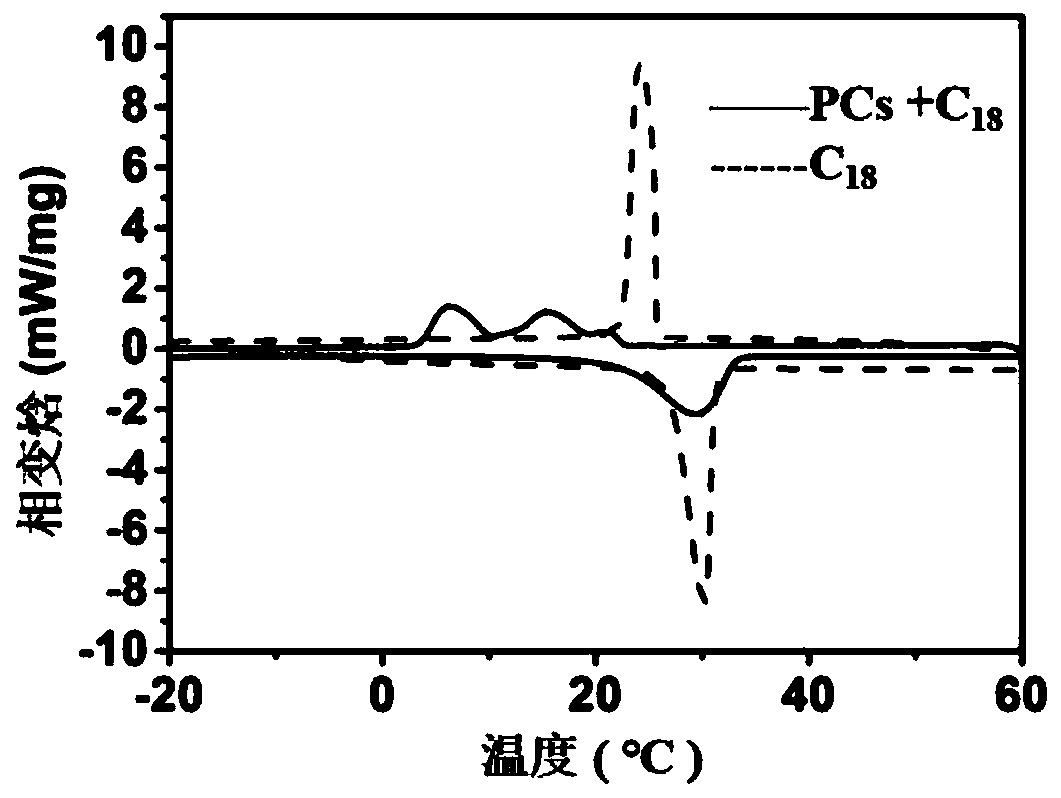

[0036] The phase transition enthalpy absorption value of the structural color dye coated with paraffin prepared in this embodiment is as follows: figure 1 As shown, it can be seen that the prepared structural color coating has a certain phase change enthalpy (144.3J / g) in the phase transition temperature range of paraffin n-hexadecane, which proves that the structural color dye can wrap the phase change material well. It is covere...

Embodiment 2

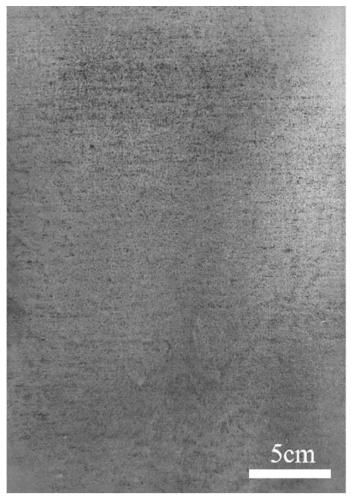

[0039]Using the emulsion polymerization method, prepare a particle diameter of 150nm monodisperse polystyrene as the shell, n-octadecane as the core-shell structure emulsion particle aqueous solution; dilute the above-mentioned microsphere solution to a concentration of 10wt% and ultrasonically disperse evenly, Then immerse the plastic substrate in the above mixed solution, and self-assemble under the environment of temperature of 80 DEG C and humidity of 90%, to obtain the structural color dye with temperature regulation performance on the surface of the plastic. The prepared structural color coating has a certain phase change enthalpy (251J / g) within the phase transition temperature range of paraffin n-decane, which proves that the structural color dye coats the phase change material well inside the structure and It has good temperature control effect. The structural color coating of the dye prepared in this example exhibits a uniform and brilliant blue-purple color over a l...

Embodiment 3

[0041] Using the emulsion polymerization method, the monodisperse polyacrylic acid with a particle size of 300nm is used as the shell, and polyethylene glycol is the core-shell structure latex particle aqueous solution of the core; The aluminum alloy substrate is immersed in the above mixed solution, and self-assembled at a temperature of 50° C. and a humidity of 50% to obtain a structural color dye with temperature regulation performance on the surface of the aluminum alloy. The prepared structural color coating has a certain phase change enthalpy (215J / g) within the phase transition temperature range of polyethylene glycol, which proves that the structural color dye coats the phase change material well inside the structure and has a relatively Good temperature regulation effect. The structural color coating of the dye prepared in this example exhibits a uniform and brilliant yellow-green color over a large area, and has excellent optical properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com