Method for reducing preparing of copper and chromium containing abrasion resisting cast iron through copper slag fusion and dilution

A technology of wear-resistant cast iron and depleted copper, applied in the field of metallurgy, can solve the problems of long process and achieve the effect of short construction period, broad application prospect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

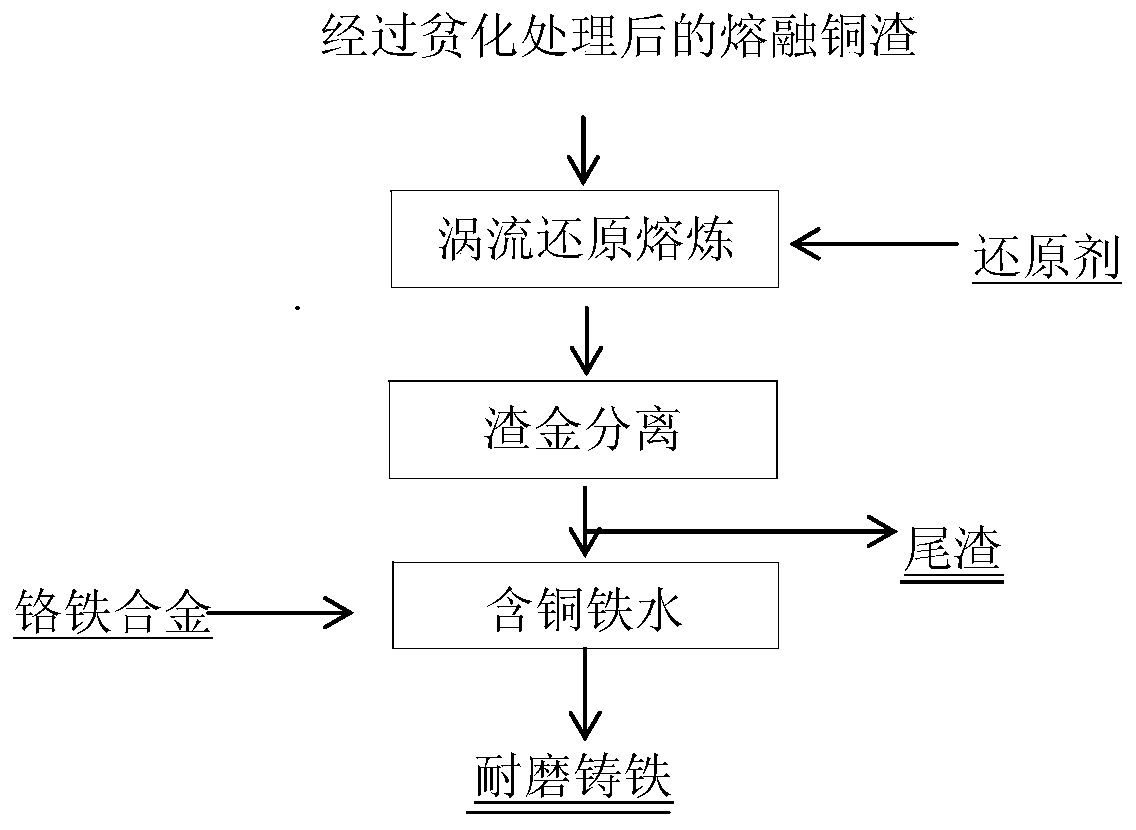

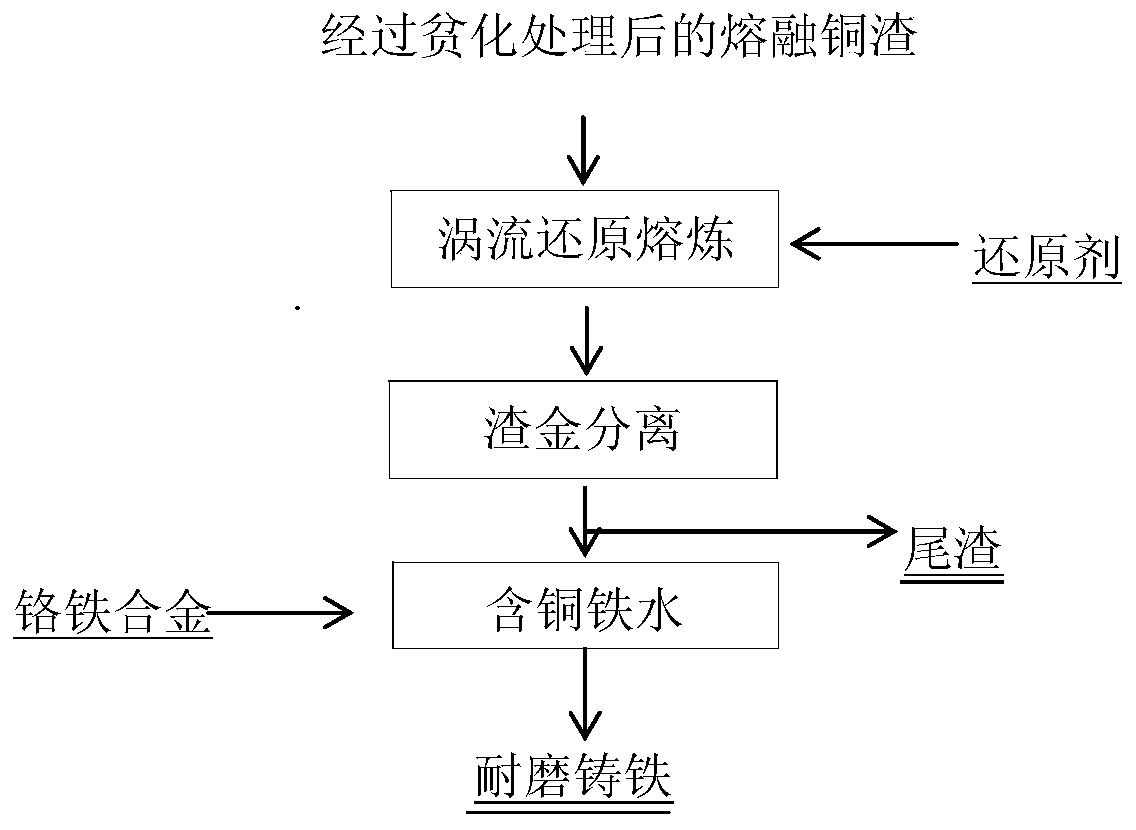

[0049] Process such asfigure 1 shown;

[0050] The molten copper slag after the depletion treatment is introduced into the reduction furnace through the chute as a raw material melt. The temperature of the molten copper slag after the depletion treatment is 1200 °C; the iron grade TFe of the molten copper slag after the depletion treatment is 45.68%, containing FeO 45.14%, Cu 0.31%, Zn 1.68%, S 0.13%, Al by mass percentage 2 o 3 4.32%, CaO 1.68%, MgO 1.45%, SiO 2 21.56%;

[0051] Raise the temperature of the raw material melt to 1400°C through the reduction furnace, insert the stirring paddle into the center of the raw material melt through the lifting device, and the height difference between the stirring paddle and the liquid surface of the raw material melt is 1 / 2 of the total height of the raw material melt; then start Stirring paddle, the raw material melt is stirred by the stirring paddle, and a molten pool with centrifugal vortex is formed in the reduction furnace;...

Embodiment 2

[0055] Method is with embodiment 1, and difference is:

[0056] (1) The temperature of the molten copper slag after depletion treatment is 1250°C; the iron grade TFe of the molten copper slag after depletion treatment is 44.96%, containing FeO 46.78%, Cu 0.32%, Zn 1.02% by mass percentage, S 0.11%, Al 2 o 3 4.33%, CaO 1.75%, MgO 1.68%, SiO 2 22.57%;

[0057] (2) The temperature of the raw material melt is raised to 1430°C, and the height difference between the stirring paddle and the liquid surface of the raw material melt is 1 / 3 of the total height of the raw material melt; the rotating speed of the stirring paddle is 150r / min;

[0058] (3) The consumption of calcium oxide and coking coal is respectively 40% of the total mass of raw material melt; 45min of vortex reduction smelting;

[0059] (4) Copper-chromium-containing wear-resistant cast iron contains Cu 0.72%, Cr 13.15%, and S 0.05% by mass percentage.

Embodiment 3

[0061] Method is with embodiment 1, and difference is:

[0062] (1) The temperature of the molten copper slag after depletion treatment is 1250°C; the iron grade of the molten copper slag after depletion treatment is TFe 44.68, containing FeO 45.32%, Cu 0.33%, Zn 1.12%, S 0.15%, Al 2 o 3 4.28%, CaO 1.69%, MgO 1.71%, SiO 2 23.57%;

[0063] (2) The temperature of the raw material melt is raised to 1450°C, the height difference between the stirring paddle and the liquid surface of the raw material melt is 1 / 3 of the total height of the raw material melt; the rotating speed of the stirring paddle is 100r / min;

[0064] (3) The consumption of calcium oxide and coking coal is respectively 35% of the total mass of the raw material melt; vortex reduction smelting for 30min;

[0065] (4) Copper-chromium-containing wear-resistant cast iron contains Cu 0.72%, Cr 13.15%, and S 0.05% by mass percentage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com