Roof cooling tower vibration and noise reduction base and construction method thereof

A technology of vibration reduction and noise reduction and construction method, which is applied in the direction of towers, floors, refrigeration plants, etc., can solve the problems of building noise pollution, work environment interference, and aggravated environmental noise pollution, and achieve the goal of improving stability and bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

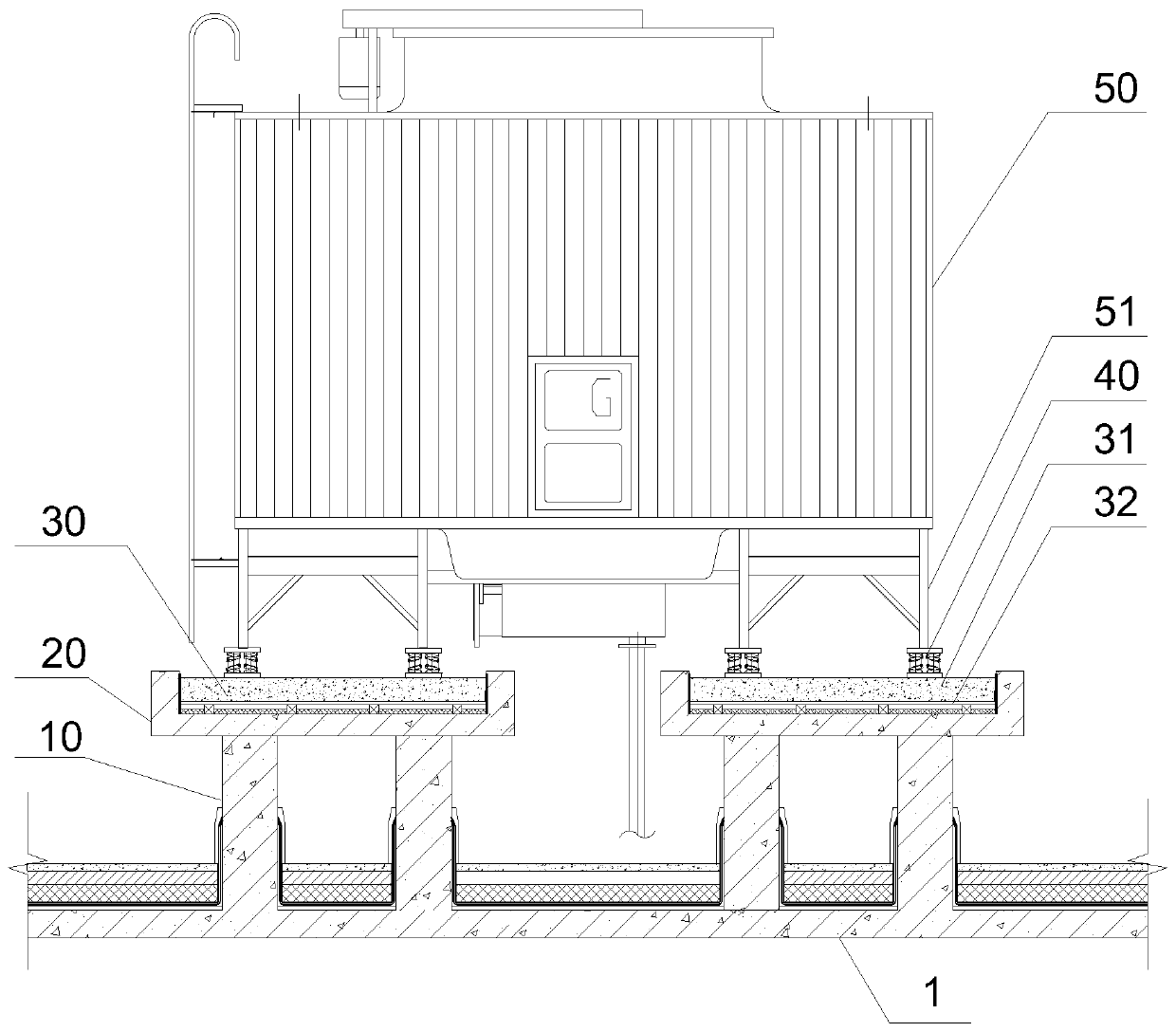

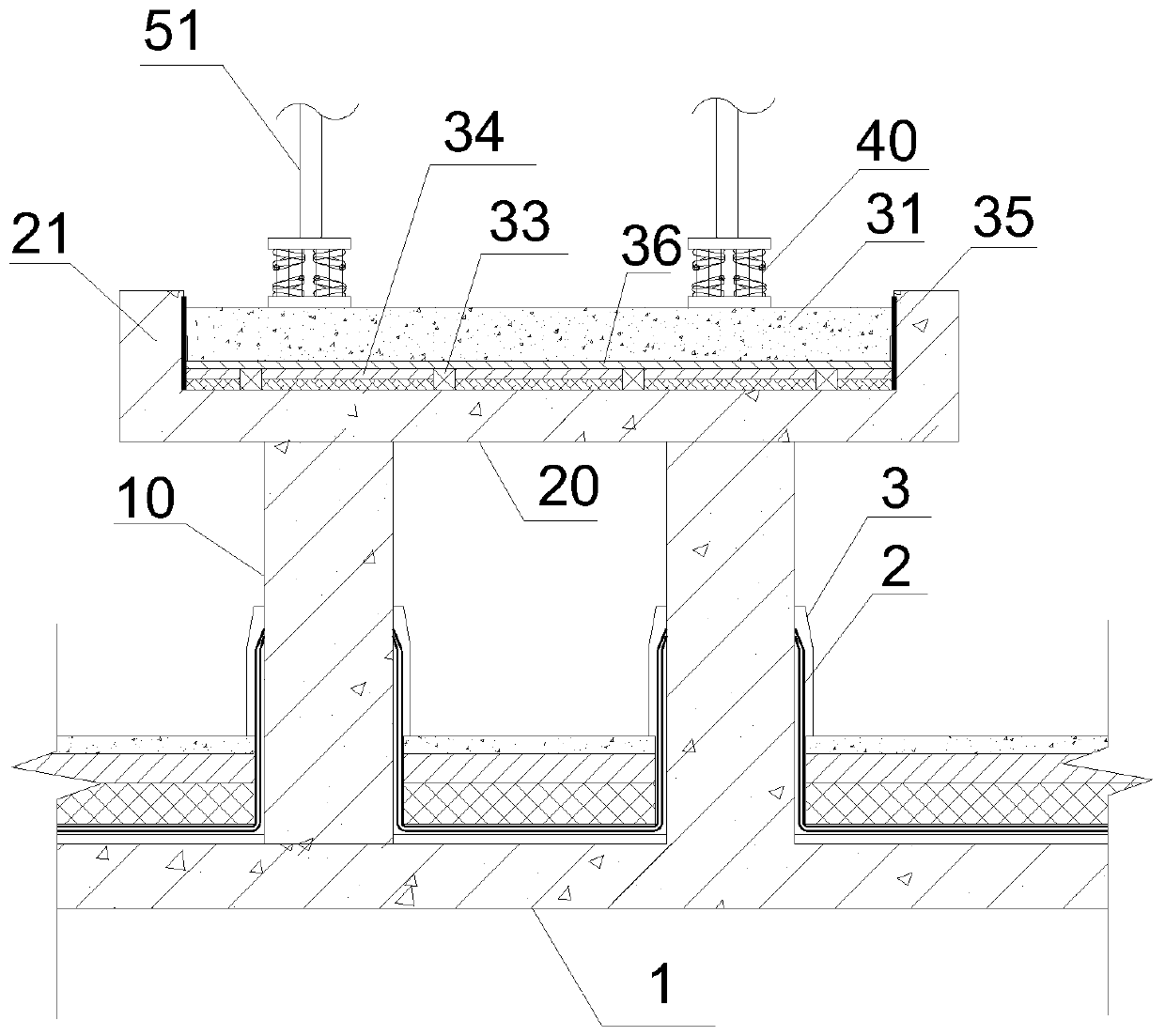

[0032] This embodiment provides a roof cooling tower vibration and noise reduction base, combined below Figure 1 to Figure 3 The vibration and noise reduction base of the roof cooling tower will be further explained. The roof cooling tower vibration and noise reduction base includes:

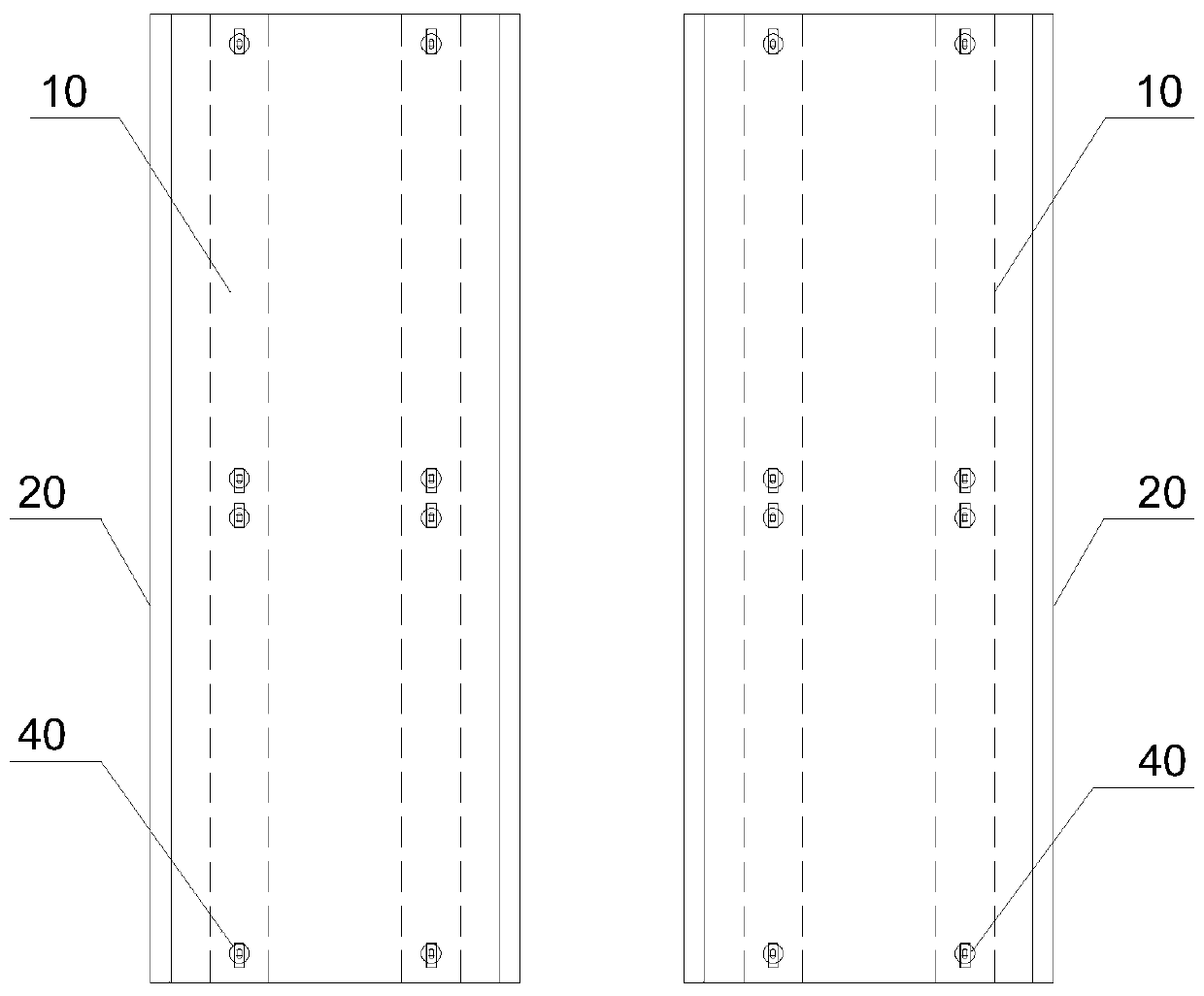

[0033] Several pairs of bottom beams 10 arranged on the floor slab 1, each pair of bottom beams 10 are arranged in parallel and spaced apart, and the bottom beams 10 and the floor slab 1 form an integral structure;

[0034] The base platform 20, the top of each pair of bottom beams 10 is connected by the base platform 20, the side of the base platform 20 is provided with a convex edge 21, and a groove is formed between the convex edges 21, the base platform 20 and the bottom beam 10 form an integrated structure;

[0035] The floating platform 30 is arranged in the groove of the base platform 20, including a force transmission plate 31, and a vibration-isolation and sound-absorbing material 32...

Embodiment 2

[0043] This embodiment provides a construction method for a roof cooling tower vibration and noise reduction base, combined below Figure 1 to Figure 3 The construction method is further introduced. The construction method includes:

[0044] In the construction of the floor slab 1, the bottom beam reinforcement of the vibration and noise reduction base of the roof cooling tower is pre-embedded, so that the bottom beam reinforcement and the floor slab reinforcement form a whole;

[0045] After the floor slab 1 is poured, the concrete at the bottom beam 10 is chiseled, and then the concrete for the bottom beam 10 and the base platform 20 are poured in vertical form, so that the base platform 20, the bottom beam 10 and the floor slab 1 form an integral structure, Wherein, the base platform 20 is provided with edges, and grooves are formed between the edges;

[0046]Lay the vibration-insulating and sound-absorbing material 32 in the groove, and then set the force-transmitting pl...

Embodiment 3

[0052] In a comprehensive commercial office building project, the cooling tower is installed on the roof of the 24th floor of the office tower, and there are 16 square cross-flow cooling towers in total. Due to the lack of good vibration reduction precautions during the installation of the cooling tower, the operating vibration of the fan motor of the cooling tower is transmitted to the building through the equipment foundation, especially on the 23rd floor with significant vibration and severe noise, which seriously affects the work and office. After on-site testing, the noise value of the roof cooling tower reached 65dB(A), and the noise detection value in the office on the 23rd floor reached 52dB(A). The value has exceeded the standard, and the cooling tower needs to be dealt with to reduce vibration and noise. In order to minimize the transmission of cooling tower vibration and noise to the lower roof through the floor, and to avoid the problems of previous vibration reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com