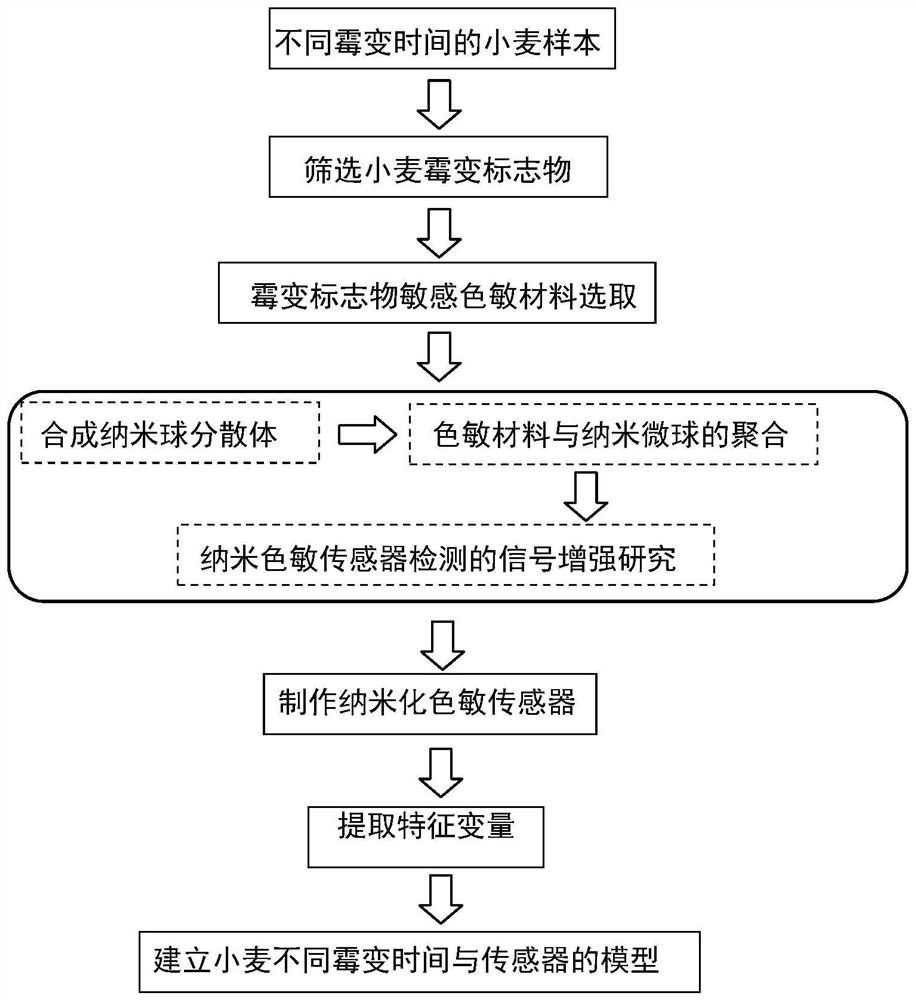

A nano-sized color-sensitive sensor and its method for discriminating the mildew degree of wheat

A color-sensitive sensor and nanotechnology, which is used in material analysis, instruments, scientific instruments and other directions by observing the effect on chemical indicators, can solve the problems of non-specific vapor results of volatiles and other problems, and achieve good color-sensitive characteristics, The effect of increasing the color rendering effect and improving the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Screening of wheat mildew characteristic gas and color-sensitive materials sensitive to it

[0044] S1. Analysis of volatile gases in the process of wheat mildew

[0045] (1) Cultivate the wheat in the constant temperature and humidity chamber with the best mildew condition, take the wheat sample in the extraction bottle with a balance and add 4-methyl-2-pentanol as an internal standard, and tighten the lid; then Heat the extraction bottle in a constant temperature water bath, insert the SPME extraction head from the rubber pad of the bottle cap into the headspace of the sample, push out the fiber head, and absorb in the headspace;

[0046] The optimal conditions for the mildew are 28°C and 80% humidity;

[0047] The amount of the sample and 4-methyl-2-pentanol is 8.0 g: 10 μL, wherein the concentration of 4-methyl-2-pentanol is 1.212 mg / L;

[0048] The water bath heating condition is 75°C;

[0049] The headspace was adsorbed for 40 minutes.

[0050] (2) ...

Embodiment 2

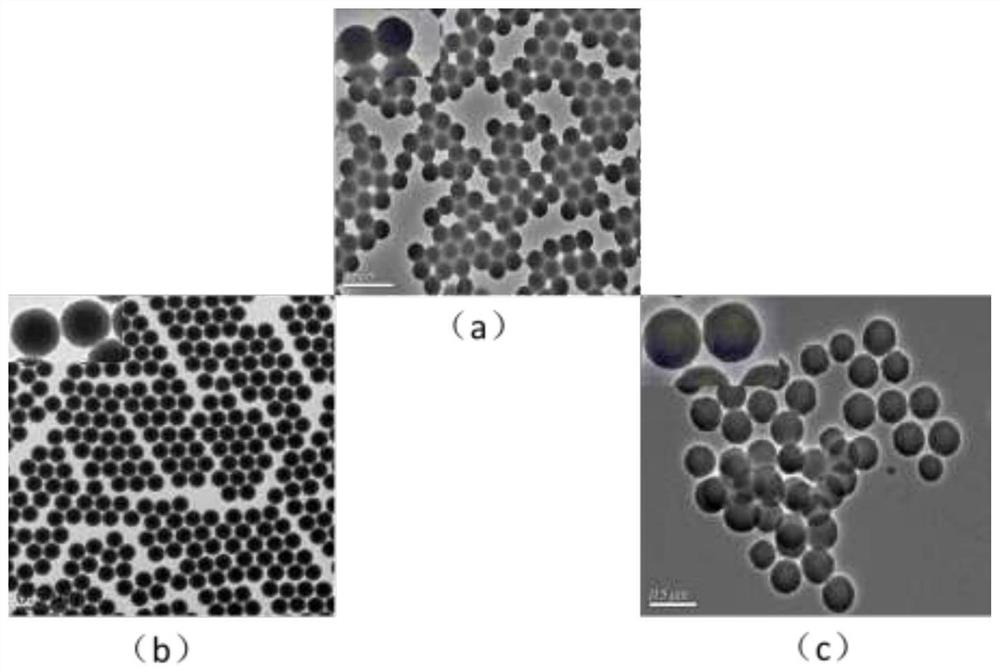

[0060] Embodiment 2: the synthesis of nano-color sensitive material

[0061] (1) Using styrene (St) and acrylic acid (AA) as monomers, ammonium persulfate (APS) as an initiator in a non-buffered medium, polystyrene-acrylic acid (P(St -co-AA)).

[0062] The specific preparation method is as follows: add 40 mL of deionized water into a 100 mL glass reaction vessel. Then it was heated to 70° C. in a constant temperature magnetic stirring water bath. After stirring at 400 rpm and purging with nitrogen for about 1 hour, 5.25 g of St and 0.18 g of AA monomer were added to the reaction vessel, and the reaction was started by adding 10 mL of a 10 g / L aqueous solution of APS. The system was controlled at 70 ° C and maintained for 8 Hour. After the reaction was completed, 0.1 mol / L HCl solution was added and centrifuged at 12,000 rpm for 30 minutes, and finally washed three times with deionized water to remove residual monomers, electrolytes and water-soluble oligomers. Finally, the...

Embodiment 3

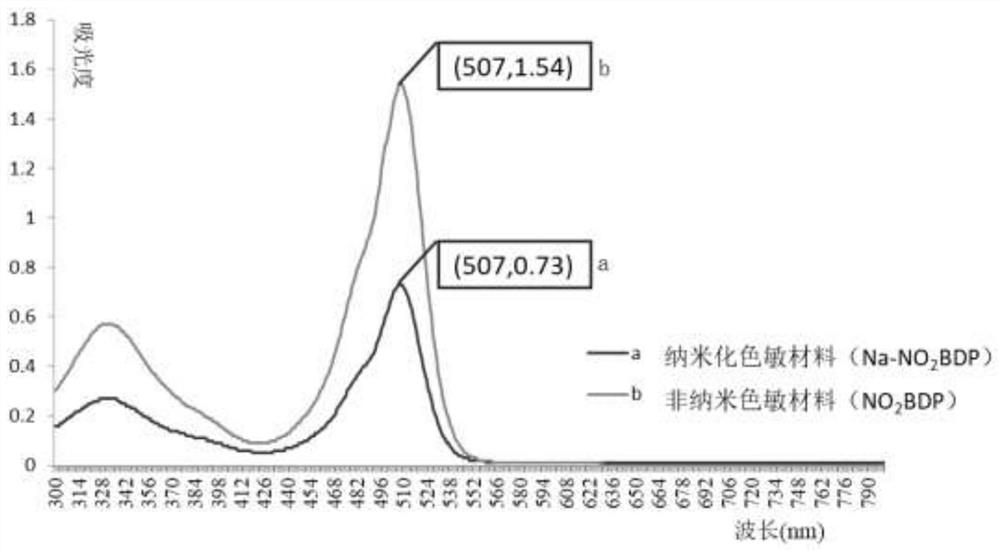

[0067] Embodiment 3: P (St-co-AA) nanosphere and the influence of different mass ratios of color-sensitive materials on material properties

[0068] P(St-co-AA)-NO 2 As a single array unit, BDP is made into a set of color-sensitive sensors to detect 1-octen-3-ol, and the response difference of each sensor array to 1-octen-3-ol is shown in Table 2 below.

[0069] By comparison, it was found that P(St-co-AA)-NO 2 When BDP captures 1-octen-3-ol molecules, its RGB response values are significantly higher than other materials.

[0070] Table 2. Different mass ratios (NO 2 BDP / PSA) and 1-octen-3-ol reaction response value mean, standard deviation and coefficient of variation

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com